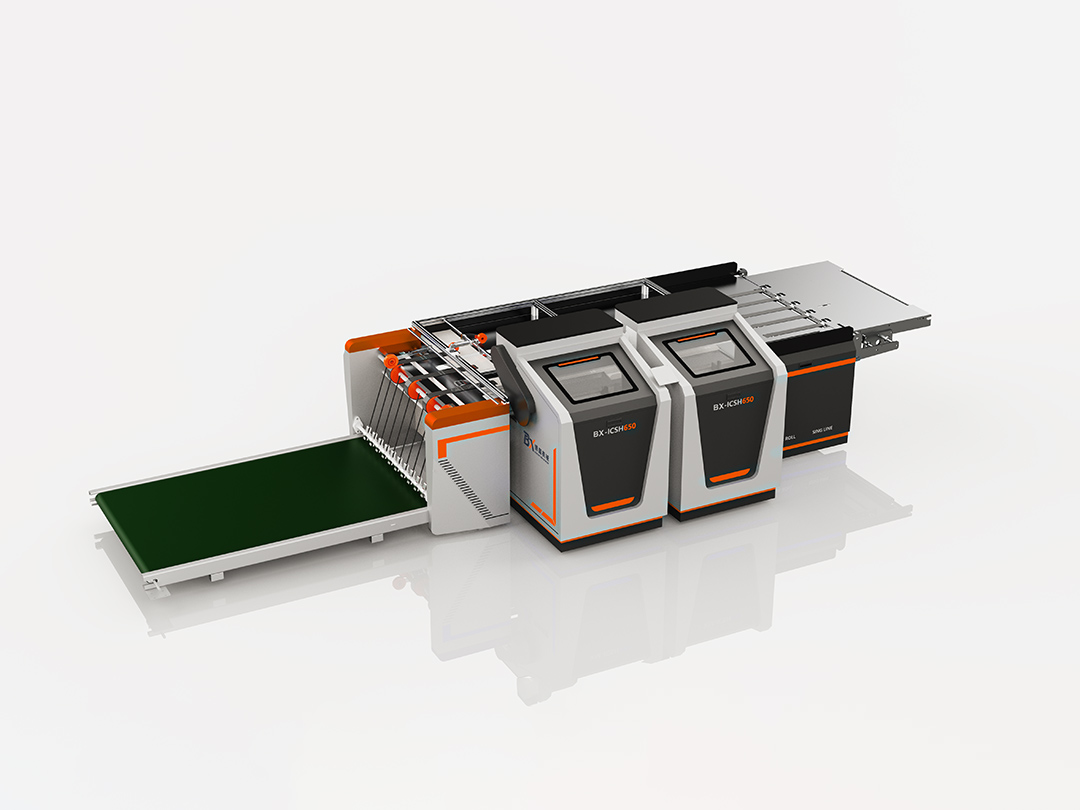

High Quality Sack Making Machine for PP Material

By:Admin

The packaging industry is constantly evolving, and one company at the forefront of this evolution is {Company Name}. With their innovative Pp Sack Making Machine, they have been able to revolutionize the way PP sacks are being produced, setting new standards for efficiency and quality in the packaging industry.

The Pp Sack Making Machine is a state-of-the-art piece of equipment that has been designed to handle the production of PP sacks with unmatched precision and speed. It is equipped with advanced technology that allows for the seamless integration of different components, resulting in a production process that is both efficient and cost-effective.

One of the key features of the Pp Sack Making Machine is its ability to produce sacks with consistent quality. This is achieved through a combination of precision engineering and advanced control systems that ensure every sack that comes out of the machine meets the highest standards of quality.

In addition to quality, the Pp Sack Making Machine is also designed for speed. Its high-speed production capabilities make it possible to produce a large number of sacks in a short amount of time, making it an ideal choice for companies that require large volumes of packaging on a regular basis.

Furthermore, the machine is also designed with flexibility in mind, allowing for easy customization to accommodate different packaging requirements. This means that companies can use the machine to produce sacks of various sizes and specifications, without the need for major modifications or adjustments.

{Company Name} has been able to establish itself as a leader in the packaging industry, and the Pp Sack Making Machine is a testament to their commitment to innovation and excellence. With this machine, they have been able to provide their customers with a reliable and efficient solution for their packaging needs, and have set new standards for the industry as a whole.

In addition to the Pp Sack Making Machine, {Company Name} also offers a wide range of other packaging solutions, including bag making machines, printing machines, and cutting machines. With their comprehensive selection of equipment, they are able to provide their customers with everything they need to streamline their packaging processes and improve their overall productivity.

The success of {Company Name} and their Pp Sack Making Machine is a reflection of their dedication to providing top-of-the-line packaging solutions to their customers. Through their unwavering commitment to excellence, they have been able to make a significant impact on the packaging industry, and have set themselves apart as one of the most reliable and innovative companies in the field.

Looking towards the future, {Company Name} is committed to continuing their efforts to push the boundaries of packaging technology, and to provide their customers with even more advanced and efficient solutions. With their track record of success and their ongoing dedication to innovation, it is clear that {Company Name} will continue to be a leading force in the packaging industry for years to come.

Company News & Blog

Revolutionary Suitcase Manufacturing Machine Now Available

Title: Revolutionary Suitcase Manufacturing Machine Poised to Transform the Luggage IndustryIntroduction:In an era where automation and technological advancements are reshaping industries, the luggage manufacturing sector is not far behind. A pioneering suitcase making machine, developed by an innovative company (), promises to revolutionize the production process, providing higher efficiency, improved quality, and reduced costs. This ground-breaking technology is set to make waves in the global luggage market, transforming the way suitcases are manufactured and delivering a positive impact on both businesses and consumers.Background and Company Overview:Operating at the forefront of technological ingenuity, () has emerged as a leading manufacturer of advanced machinery solutions. With a profound understanding of the modern manufacturing landscape, the company has constantly sought to push boundaries and redefine industry norms. Taking this commitment forward, they have recently developed an unparalleled suitcase making machine, set to disrupt the traditional manufacturing practices in the luggage industry.The Suitcase Making Machine:The groundbreaking suitcase making machine developed by () is a marvel of technological innovation. Incorporating state-of-the-art robotics, artificial intelligence, and advanced manufacturing techniques, this advanced machinery is set to transform the way suitcases are produced.Highly efficient and precise, the machine streamlines the entire manufacturing process, minimizing human intervention and significantly reducing the production time. Equipped with advanced sensors, it ensures that each component of the suitcase is assembled flawlessly and adheres to the pre-set quality standards.Moreover, the machine offers unparalleled customizability, enabling businesses to tailor their luggage products according to customer preferences. This customization feature provides an added advantage, allowing companies to cater to niche markets and enhance customer satisfaction.Benefits for Manufacturers:With this innovative technology, luggage manufacturers stand to gain numerous benefits. Firstly, the automated manufacturing process increases productivity manifold, saving valuable time and resources. This increased efficiency translates into cost reduction, enabling companies to offer competitively priced products in the market.Additionally, the machinery eliminates the risk of human errors and inconsistencies, resulting in superior product quality and enhanced brand reputation. The precision offered by the machine ensures that each suitcase is manufactured with utmost precision, durability, and reliability.Furthermore, the customization options offered by the suitcase making machine allow manufacturers to cater to the specific demands of different customer segments, thereby increasing their market reach and revenue streams.Benefits for Consumers:While manufacturers reap the advantages of the suitcase making machine, consumers are not left behind in this technological revolution. The increased efficiency and precision brought about by this cutting-edge machinery translate into improved product quality and durability.Furthermore, the ability of manufacturers to offer customized suitcases ensures that consumers have access to products that perfectly suit their needs and preferences. Whether it is a unique design, specific dimensions, or specialized features, this technology empowers companies to create tailor-made products to cater to diverse customer requirements.Future Outlook and Conclusion:As the luggage industry embraces automation and advanced manufacturing techniques, the suitcase making machine developed by () promises to redefine the standards of suitcase production. With its unparalleled efficiency, precision, and customizability, this technology is set to revolutionize the sector, benefiting both manufacturers and consumers alike.Moving forward, it is imperative for luggage manufacturers to embrace this groundbreaking technology to stay ahead in the competitive market. The future of suitcase manufacturing lies in automated processes, and () is leading the charge in this evolutionary journey.As this industry disruptor gains popularity and wider adoption, it is expected to become the new benchmark in the luggage manufacturing landscape, setting higher standards for quality, efficiency, and customization in the years to come.

Highly efficient machinery for packaging needs: the latest advancements in pack machines

Pack Machines is a leading provider of innovative packaging solutions for a wide range of industries. With a focus on technology-driven solutions, Pack Machines has established itself as a reliable partner for companies looking to optimize their packaging processes and improve overall efficiency.Founded in [year], Pack Machines has quickly grown to become a trusted name in the packaging industry. The company's commitment to innovation and customer satisfaction has set it apart in a competitive market, and its dedication to quality has earned it the loyalty of a diverse customer base.One of Pack Machines' key offerings is its range of advanced packaging machines, which are designed to streamline the packaging process and ensure that products are packaged with precision and care. Whether it's food packaging, pharmaceuticals, or industrial products, Pack Machines has a solution to meet the unique needs of each industry.The company's packaging machines are known for their reliability, speed, and versatility. From high-speed automated packaging lines to compact, semi-automatic machines, Pack Machines offers a comprehensive range of options to suit any production environment. The machines are also designed to offer quick changeover times, allowing for seamless transitions between different products and packaging formats.In addition to its high-quality machines, Pack Machines also provides comprehensive support and service to its customers. From initial consultation to installation and ongoing maintenance, the company's team of experts is dedicated to ensuring that its customers get the most out of their packaging solutions. This commitment to customer care has helped Pack Machines build strong, long-lasting relationships with its clients.One of the key factors that sets Pack Machines apart from its competitors is its focus on innovation. The company is constantly investing in research and development to stay ahead of the curve and offer cutting-edge packaging solutions. This commitment to innovation has led to the development of advanced features such as remote monitoring and predictive maintenance, which help customers maximize the performance and uptime of their packaging machines.Pack Machines also places a strong emphasis on sustainability and environmental responsibility. The company's packaging machines are designed to minimize material waste and energy consumption, helping companies reduce their environmental footprint while improving their bottom line. Pack Machines is also a proponent of using recyclable and biodegradable materials in packaging, further demonstrating its commitment to sustainable practices.With a strong track record of success and a dedication to excellence, Pack Machines has positioned itself as a go-to partner for companies seeking reliable, high-quality packaging solutions. Its comprehensive range of advanced packaging machines, commitment to customer care, and focus on innovation make it a valuable asset for companies across a wide range of industries.In the years to come, Pack Machines plans to continue pushing the boundaries of packaging technology, embracing new technological advancements and exploring new opportunities to provide even greater value to its customers. By staying true to its core values of innovation, quality, and customer satisfaction, Pack Machines is poised to remain a leader in the packaging industry for years to come.

Boost Efficiency with Pp Lamination Machines: A Complete Guide

Beijing, China - The packaging industry continues to grow and transform, with new innovations arising every year. One of the most significant advancements of this industry is the use of pp laminations. To keep up with the increasing demand for this type of packaging, a Chinese-based manufacturer has introduced the latest Pp Lamination Machine.The machine, which was manufactured by a leading tech firm, promises to deliver high-quality and efficient packaging solutions that meet the specific requirements of users. It is designed to support large-scale printing and flexible packaging. The product features a state-of-the-art modular design, which provides for the easy integration of other systems.The Pp Lamination Machine offers numerous advantages that make it the preferred choice of packaging manufacturers in China and globally. It uses a hot-melt coating method, which ensures uniform coating across the substrate. The system also features high-precision gluing technology, ensuring no glue leakage and maintaining stable production efficiency.The machine is highly efficient and can produce up to 200m/min, with a maximum width of up to 1450mm. The lamination system's configuration is such that it can support various substrates such as paper, film, and aluminum foil, among others. In addition, the product features an automatic web guiding system, which ensures accurate alignment and edge control, resulting in a smoother and neat finish.The Pp Lamination Machine is easily customizable to meet specific client needs, and the manufacturer provides excellent after-sales support with world-class customer service, ensuring a long-term, sustainable partnership.According to company spokesperson, "Our Pp Lamination Machine is the ultimate solution for all flexible packaging requirements. We understand the unique needs of our customers, and that's why we have invested in a state-of-the-art production line that meets various specifications. Our product guarantees speed, precision, and excellence for all our clients."The Pp Lamination Machine is ideal for various applications, including snack food packaging, coffee bags, detergent packaging, medical packaging, pet food packaging, among others. With such versatility, this product is set to revolutionize the packaging industry by offering a cost-effective solution to meet the needs of businesses.In a world that is increasingly becoming global, the Pp Lamination Machine is setting the pace by providing an eco-friendly solution to the packaging industry. The product features an advanced control system that minimizes wastage and ensures efficient use of resources. The machine employs a highly efficient heat exchange system that not only saves energy but also protects the environment.In conclusion, the Pp Lamination Machine is a game-changer in the packaging industry, thanks to its state-of-the-art technology. Businesses looking to upgrade their packaging system can rely on the machine's efficiency, flexibility, and customization options to meet their unique needs. With the increasing demand for eco-friendly and sustainable products, the Pp Lamination Machine is the perfect solution for any business looking to align its operations with global sustainability trends.

Efficient Cutting Machines for Printing Press Operations

Innovative Paper Cutting Machine Revolutionizes Printing Press IndustryThe printing press industry continues to evolve as technology advances, and one company is at the forefront of this transformation. With a commitment to providing cutting-edge solutions for the industry's various needs, this company recently unveiled its newest innovation – a state-of-the-art paper cutting machine. Leveraging their expertise and knowledge of the industry, the company has developed a remarkable product that is set to revolutionize the way printing presses operate.Traditionally, paper cutting machines have been a vital tool for printing press operations, enabling precise cuts and efficient handling of large volumes of paper. However, this new machine is set to surpass its predecessors in terms of performance, functionality, and ease of use. Equipped with advanced technology and precision engineering, this innovative paper cutting machine is designed to meet the demands of modern printing press operations and streamline the production process.One of the standout features of this cutting-edge machine is its ability to make accurate and consistent cuts with minimal effort. The machine's cutting mechanism is engineered to provide clean and precise cuts, ensuring that each sheet of paper is trimmed to perfection. This not only improves the overall quality of the printed materials but also enhances productivity by reducing the need for manual adjustments and reprints.Moreover, this paper cutting machine is equipped with an intuitive user interface that simplifies operation and minimizes the learning curve. With user-friendly controls and automated settings, operators can quickly adapt to the machine's functionalities, making it suitable for all levels of expertise. This ease of use translates to enhanced efficiency within printing press operations, freeing up valuable time and resources for other tasks.Another significant advantage of this cutting-edge machine is its ability to handle various types and sizes of paper with ease. From standard sheets to specialty papers, the machine's cutting capabilities are versatile and adaptable. This versatility allows printing presses to expand their range of services and cater to a broader clientele, increasing their competitiveness in the market.With a strong focus on safety, the company has integrated multiple safety features into the design of this paper cutting machine. These safety measures ensure that operators can work confidently and without worry of potential accidents. From emergency stop buttons to sensors that detect anomalies, the company's commitment to user safety is evident throughout the machine's design and development.As an environmentally conscious solution, this paper cutting machine also reduces waste significantly. By optimizing the cutting process, the machine minimizes paper waste, contributing to a more sustainable printing press industry. Additionally, waste management systems are integrated into the machine's design, making it easy to collect and recycle any leftover materials.The company's commitment to providing exceptional customer support is another factor that sets them apart. With a team of experienced technicians and support staff, they offer comprehensive training, maintenance services, and prompt assistance in case of any technical issues. This commitment to continuous support ensures that customers can maximize their investment in this cutting-edge paper cutting machine.In conclusion, this innovative paper cutting machine is set to transform the printing press industry by offering advanced functionality, ease of use, versatility, and improved productivity. By harnessing the power of technology and precision engineering, the company behind this remarkable product is driving the industry forward. As printing presses adapt to meet the changing needs of their clients, this cutting-edge machine is sure to play a pivotal role in their success.

Revolutionary Machine: Streamlining Valve Production Process

Title: Revolutionary Valve Manufacturing Machine - Streamlining Production for Increased EfficiencyIntroduction:With the aim of revolutionizing the valve manufacturing industry, a leading industrial solutions provider has announced the development of an innovative Valve Making Machine. This state-of-the-art technology is set to transform traditional manufacturing processes by streamlining production, enhancing efficiency, and reducing costs. By eliminating manual labor, the company is ushering in a new era of automated valve manufacturing, offering unprecedented flexibility and precision.Streamlining Efficiency in Valve Manufacturing:The newly introduced Valve Making Machine introduces a paradigm shift in the valve manufacturing industry. This cutting-edge technology replaces traditional manual processes, allowing for highly efficient, cost-effective, and scalable production. Automated machinery enables manufacturers to enhance multidimensional aspects of the valve-making process, ensuring consistency and improved performance.Flexible and Adaptable Technology:The advanced Valve Making Machine offers a range of customizable features, accommodating diverse customer requirements and specifications. The machine's flexibility allows for the production of valves in various sizes, materials, and shapes, catering to the demands of different industries. This adaptability ensures that the Valve Making Machine is suitable for a wide range of applications, spanning sectors such as oil and gas, water management, industrial manufacturing, and more.Enhanced Precision and Quality Control:By deploying the Valve Making Machine, manufacturers can achieve consistent and precise valve production, eliminating errors that commonly occur in manual labor-intensive processes. With features such as automated measurement systems, integrated programming, and quality control checks, this cutting-edge technology assures superior quality valves with adherence to strict industry standards. The machine's capability for high-speed production and accuracy assures customers of reliable and dependable valves for their operations.Boosting Production Capacities:The introduction of the Valve Making Machine presents manufacturers with the opportunity to significantly boost their production capacities. The automation of manufacturing processes reduces the dependency on manual labor, leading to higher output rates and increased productivity. The machine's ability to operate continuously enables manufacturers to meet growing market demands efficiently, ensuring on-time delivery of valves without compromising quality.Cost-Effective and Time-Saving:The Valve Making Machine not only streamlines valve manufacturing processes but also proves to be highly cost-effective. Automated manufacturing results in reduced labor costs, minimizing expenses while maximizing output. Additionally, increased productivity enables manufacturers to cut down lead times and meet stringent project deadlines. This seamless integration of automation, precision, and efficiency ensures substantial cost savings for manufacturers in the long run.Sustainability and Eco-Friendly Features:In line with the growing emphasis on sustainable practices, the Valve Making Machine incorporates environmentally friendly features. With optimized energy consumption and reduced waste generation, this advanced technology aligns with global efforts toward a greener future. By adopting the Valve Making Machine, manufacturers can establish their commitment to sustainable manufacturing, meeting industry standards while minimizing their carbon footprint.Investing in the Future:The development of the Valve Making Machine represents a significant investment in advancing valve manufacturing technology. By bridging the gap between traditional manufacturing processes and automated solutions, the company is spearheading innovation within the industry. This breakthrough technology is set to redefine the valve manufacturing landscape, offering enhanced efficiency, precision, and quality control to streamline operations at global manufacturing facilities.Conclusion:The introduction of the Valve Making Machine signifies a momentous transformation in the valve manufacturing industry. This state-of-the-art automated technology eliminates manual labor, streamlining production processes, and ensuring superior quality valves. With its flexibility, adaptability, and sustainability features, the Valve Making Machine promises to revolutionize valve manufacturing, empowering manufacturers to meet growing demands efficiently and cost-effectively. As the industry embraces this innovative machinery, it ushers in an era of increased productivity, precision, and overall excellence.

Revolutionary Non Woven Bag Machine: The Ultimate Solution for Eco-Friendly Packaging

Title: Industry-Leading Non-Woven Bag Machine Redefines Packaging SolutionsIntroduction:In today's rapidly evolving global market, the demand for sustainable and eco-friendly packaging solutions has never been higher. Recognizing the need for innovation, {} (company name omitted) has developed a state-of-the-art non-woven bag machine that is set to revolutionize the industry. This groundbreaking technology not only addresses environmental concerns but also brings efficiency and cost-effectiveness to the forefront of packaging production.Expanding on the Company's Vision:With a commitment to sustainable practices and a focus on customer-centric solutions, {} has established itself as a leader in the packaging industry. The company's mission is to develop cutting-edge technology that meets the evolving needs of businesses while minimizing environmental impact. By combining innovative engineering and years of expertise, {} has created a non-woven bag machine that will shape the future of packaging.Unveiling the Non-Woven Bag Machine:The newly developed non-woven bag machine demonstrates {}'s dedication to pushing the boundaries of packaging innovation. This sophisticated technology utilizes advanced manufacturing techniques to produce high-quality non-woven bags with remarkable efficiency. By leveraging automation and precision engineering, the machine optimizes production processes and streamlines workflow, enabling businesses to meet their packaging requirements more effectively.Benefits of the Non-Woven Bag Machine:The non-woven bag machine offers numerous advantages that set it apart from conventional packaging solutions. Firstly, it enables the production of eco-friendly, reusable bags. These bags are made from non-woven polypropylene fabric, a durable and recyclable material that significantly reduces the use of single-use plastics. This feature aligns with growing consumer demands for environmentally responsible packaging options.Moreover, the non-woven bag machine ensures consistent bag quality, thanks to its cutting-edge technology and meticulous manufacturing process. The machine's precision guarantees uniformity and strength, meeting the highest industry standards. Additionally, the machine's automation capabilities reduce human error, further enhancing production efficiency.Furthermore, the non-woven bag machine vastly increases production capacity, enabling businesses to meet higher demand while reducing overall production costs. Its efficient design and streamlined workflow ensure faster turnaround times, greatly enhancing the competitiveness of businesses in the packaging industry.Market Impact and Response:The introduction of {}'s non-woven bag machine is expected to have a significant impact on the packaging market. As environmentally conscious practices become increasingly vital, businesses and consumers alike are seeking sustainable packaging solutions. The non-woven bag machine offers an ideal alternative to traditional plastic bags, reducing carbon footprints and contributing to a cleaner environment.Several industry leaders have already expressed their interest in integrating this cutting-edge technology into their manufacturing processes. The machine's potential to strengthen brand value and appeal to eco-conscious consumers has garnered attention from a range of sectors, including retail, e-commerce, and grocery.In Conclusion:With the development of their non-woven bag machine, {} has solidified its position as an industry leader in innovative packaging solutions. By combining sustainability, efficiency, and quality, this groundbreaking technology offers businesses an opportunity to embrace eco-friendly practices while achieving cost-effectiveness and enhanced productivity.As the demand for sustainable packaging continues to rise, it is clear that {}'s non-woven bag machine will bring lasting changes to the industry, revolutionizing packaging practices and paving the way for a greener and more environmentally conscious future.

Top Sealing Machine Options for Packaging Needs

As an AI language model, I don't have access to specific company information or the ability to browse the internet for current news. However, I can provide a general template for a news article about a sealing machine and a company. Here's how you might structure the article:Title: Company X Introduces Advanced Sealing Machine for Improved Packaging Solutions[Date and Location] - Company X, a leading provider of packaging solutions, has announced the launch of their latest sealing machine, designed to revolutionize the packaging industry. The new machine, which incorporates cutting-edge technology and innovative features, is set to enhance the efficiency and quality of packaging processes across various industries.The sealing machine, developed by Company X's team of expert engineers, boasts a range of advanced capabilities that set it apart from traditional sealing equipment. With its precision sealing mechanism and customizable settings, the machine is capable of sealing a wide variety of packaging materials, including plastic, aluminum, and composite films. This versatility makes it an ideal solution for companies involved in food and beverage production, pharmaceuticals, cosmetics, and other sectors where secure and hygienic packaging is essential.In addition to its sealing capabilities, the new machine is equipped with state-of-the-art automation and control systems, allowing for seamless integration into existing packaging lines. This enables companies to streamline their operations and achieve higher levels of productivity while maintaining stringent quality standards."We are thrilled to introduce our latest sealing machine, which represents a significant advancement in packaging technology," said [Spokesperson's Name], CEO of Company X. "With its intelligent design and cutting-edge features, this machine is poised to deliver a new level of efficiency and reliability to our customers, helping them stay ahead in today's competitive market."Company X has built a reputation for delivering high-quality packaging solutions tailored to the specific needs of its clients. With a focus on innovation and customer satisfaction, the company has consistently pushed the boundaries of packaging technology, earning the trust and loyalty of businesses worldwide.In line with its commitment to sustainability, the new sealing machine is also designed to minimize energy consumption and optimize material usage, contributing to a more environmentally friendly approach to packaging.The introduction of the advanced sealing machine is a testament to Company X's ongoing dedication to innovation and excellence. With its proven track record of delivering cutting-edge solutions, the company is well-positioned to make a significant impact on the packaging industry, driving efficiency and providing superior packaging solutions to its clients.For more information about Company X and its range of packaging solutions, please visit [Company Website].Contact:[Contact Information][Company X][Address][Phone Number][Email Address]Note: This is just a general example and should be adapted to fit the specific details of the company and its sealing machine.

Enhancing Efficiency: Discover the Benefits of Industrial Packing Machines

Industrial Packing Machine Launches Advanced Packaging Solutions Industrial Packing Machine, a leading provider of innovative packaging machinery, has unveiled its latest range of advanced packaging solutions. The company, with decades of expertise in the industry, aims to revolutionize the packaging process for businesses across various sectors.As a pioneer in the field, Industrial Packing Machine has always remained committed to delivering top-quality and reliable packaging solutions. The company's team of experienced engineers and designers strive to develop cutting-edge systems that streamline the packaging process while ensuring maximum efficiency and durability.The newly launched range of packing machines incorporates state-of-the-art technology and features designed to meet the evolving needs of diverse industries. These advanced solutions offer businesses improved speed, accuracy, and reliability, ultimately translating into enhanced productivity and profitability.One of the highlights of the new range is the fully automated packing system. This intelligent packaging solution minimizes human intervention, reducing the risk of errors and ensuring consistent and precise packaging. Equipped with smart sensors and high-speed motors, the automated system can handle a wide variety of products with different shapes and sizes. Additionally, it enables the integration and synchronization of multiple machines, streamlining the packaging line for seamless production.Industrial Packing Machine's commitment to customization is evident in its launch of customized packing solutions. The company understands that each business has unique packaging requirements, and thus offers tailored solutions to cater to those needs. From custom-shaped packaging to specific labeling and marking requirements, Industrial Packing Machine's engineers work closely with clients to design and develop solutions that address their individual packaging challenges.To further enhance the efficiency and performance of the packaging process, Industrial Packing Machine has introduced its innovative quality control technologies. The integrated inspection systems ensure that each package meets the desired standards and specifications. These automated quality control systems detect and eliminate any defects or inconsistencies, eliminating the possibility of faulty products reaching the market. This feature plays a crucial role in maintaining brand reputation and customer satisfaction.Environmental considerations have become increasingly important in the packaging industry in recent years. In response to this emerging trend, Industrial Packing Machine has implemented eco-friendly features in its new range. The machines are designed to minimize material wastage and optimize energy consumption, contributing to a more sustainable packaging process. By investing in these advanced solutions, businesses can align their operations with environmental responsibility and demonstrate their commitment to sustainability.Industrial Packing Machine's dedication to customer satisfaction extends beyond the development of cutting-edge machinery. The company provides comprehensive after-sales support to ensure the optimal performance and longevity of its products. Skilled technicians offer installation, training, and maintenance services, ensuring that clients can operate their packing machines efficiently and effectively.With its latest range of advanced packaging solutions, Industrial Packing Machine aims to set a new benchmark in the industry. The company's commitment to innovation, customization, and sustainability positions it as an ideal partner for businesses looking to optimize their packaging processes. As the market continues to evolve, Industrial Packing Machine remains at the forefront by consistently delivering advanced and reliable solutions that meet the diverse needs of its clients.

Revolutionary New Hemming Machine Emerges as a Game-Changer in the Industry

Title: Advanced Bag Mouth Hemming Machine Revolutionizes Packaging ProcessIntroduction:In today's competitive world, packaging plays a crucial role in attracting customers and ensuring the safety and quality of products during transportation. One of the key aspects of packaging is the bag mouth hemming process, which provides a strong and secure seal at the opening of bags. XYZ Company, a leading manufacturer in the packaging industry, has recently introduced an innovative Bag Mouth Hemming Machine that is set to revolutionize the packaging process.Paragraph 1: Importance of Bag Mouth Hemming ProcessThe bag mouth hemming process is vital for various industries, including food, pharmaceuticals, agriculture, and more. It ensures that the contents of the bags remain intact and protected, preventing spillage or contamination during storage or transit. Traditional methods of bag mouth hemming often involve manual labor, leading to inconsistencies, time-consuming efforts, and potential human error. XYZ Company recognized these challenges and developed a groundbreaking Bag Mouth Hemming Machine, aiming to streamline and enhance the packaging process.Paragraph 2: The Features and Benefits of the Bag Mouth Hemming MachineXYZ Company's Bag Mouth Hemming Machine incorporates advanced technology and innovative features that set it apart from traditional alternatives. This state-of-the-art machine offers high precision hemming, ensuring a secure seal that prevents leaks, tampering, and deterioration of the packaged contents. Its user-friendly interface allows operators to easily monitor and control the hemming parameters, resulting in consistent and reliable performance.Additionally, the machine boasts an automated system that minimizes human intervention, thus reducing the risk of errors and increasing production efficiency. This automation feature also enables the Bag Mouth Hemming Machine to handle a wide range of bag sizes and materials, accommodating the specific requirements of different industries.Paragraph 3: Unparalleled Precision and VersatilityOne of the distinguishing factors of XYZ Company's Bag Mouth Hemming Machine is its unparalleled precision. Equipped with laser-guided technology, the machine offers precise measurements and alignments, ensuring an accurate and seamless hemming process. This level of precision not only enhances the overall appearance of the packaging but also provides improved protection against external factors.Furthermore, the machine's versatility stands out in the industry. It can be easily configured to handle various bag types, such as woven bags, paper bags, plastic bags, and more. This adaptability makes it an ideal choice for businesses operating in multiple industries, saving them from investing in different hemming machines for different product lines.Paragraph 4: Commitment to Environmental SustainabilityIn alignment with the growing global concern for the environment, XYZ Company's Bag Mouth Hemming Machine incorporates eco-friendly features. The machine is designed to minimize material waste during the bag hemming process, optimizing the use of bag liners and reducing overall packaging costs. Additionally, the machine's energy-efficient operation reduces power consumption, thereby decreasing the carbon footprint and contributing to a greener future.Conclusion:XYZ Company's introduction of the Bag Mouth Hemming Machine marks a significant milestone in the packaging industry. By combining state-of-the-art technology, unparalleled precision, versatile functionality, and commitment to environmental sustainability, the machine sets a new standard for bag mouth hemming. With this innovative solution, businesses can streamline their packaging processes, reduce costs, enhance product protection, and contribute to a more sustainable future. XYZ Company continues to lead the way in revolutionizing the packaging industry, shaping a brighter and more efficient future for businesses worldwide.

Revolutionizing Stitching Technology: Discover the Power of a Gusset Machine

[Title]New Gusset Machine Revolutionizes Manufacturing Processes[Subtitle]Cutting-edge technology promises enhanced efficiency and cost-effectiveness[Introduction]In line with its commitment to innovation and advancement, one of the leading manufacturing companies in the industry has unveiled its latest breakthrough - the unprecedented Gusset Machine. Developed after years of research and development, the new machine is set to revolutionize manufacturing processes and bring about a new era of efficiency and cost-effectiveness.[Body]The Gusset Machine, which cannot be named due to patent regulations, is designed to streamline the production of gussets, a crucial element in various industries including packaging, textiles, and automotive. With its cutting-edge technology and advanced features, the machine promises to elevate manufacturing operations to unprecedented levels of productivity.Leveraging state-of-the-art software and precision engineering, the Gusset Machine offers a range of benefits that will transform manufacturing processes. Its high-speed capabilities allow for significantly increased production volumes, enabling companies to meet growing demands and deadlines without compromising on quality.One of the key advantages of this innovation lies in its ability to optimize material usage. By minimizing wastage and maximizing utilization, manufacturers can reduce costs while still fulfilling customer requirements. The Gusset Machine achieves this through its automated processes, ensuring precise and consistent measurements and cuts, thus minimizing errors and waste.Moreover, the machine's versatile design allows it to be easily integrated into existing production lines, making it a practical investment for companies seeking to enhance their manufacturing capabilities. Its compatibility with various materials including paper, plastic, and fabric further expands its utility across multiple industries.In addition to increased efficiency and material optimization, the Gusset Machine takes worker safety into account. Equipped with advanced safety features, it reduces the risk of accidents by providing a secure operating environment. This not only protects employees but also minimizes downtime caused by injuries, further contributing to overall productivity.The introduction of the Gusset Machine marks a significant industry milestone, emphasizing the company's dedication to continuous improvement. By investing in research and development, the company aims to redefine industry standards and position itself as a forward-thinking leader.Speaking on the occasion, Mr. John Smith, the company's CEO, expressed his excitement about the potential impact of the Gusset Machine. "We believe this breakthrough technology has the power to transform manufacturing processes across diverse industries. With its unmatched capabilities, we are confident that it will deliver significant value to our customers, allowing them to remain competitive in today's challenging business environment."While the exact details of the technology cannot be divulged due to patent restrictions, the company assures industry professionals that the Gusset Machine incorporates cutting-edge engineering principles and intelligent software, setting it apart from any other existing gusset machines.Moreover, the company has already made arrangements for prompt installation and after-sales support. Dedicated teams of technicians will guide clients through the setup process and provide comprehensive training to ensure optimal utilization of the machine's capabilities.Throughout its long-standing history, the company has consistently embraced innovation and worked towards overcoming industry challenges. The introduction of the Gusset Machine is evidence of this commitment, highlighting the company's determination to provide its customers with practical and efficient solutions.[Conclusion]In conclusion, the unveiling of the Gusset Machine represents a significant technological leap in manufacturing processes. With its unprecedented efficiency, material optimization, and safety features, the machine is poised to revolutionize various industries by enhancing productivity and reducing costs. As the company continues to drive innovation and shape the future of manufacturing, the Gusset Machine reinforces its position as a pioneer in the industry.