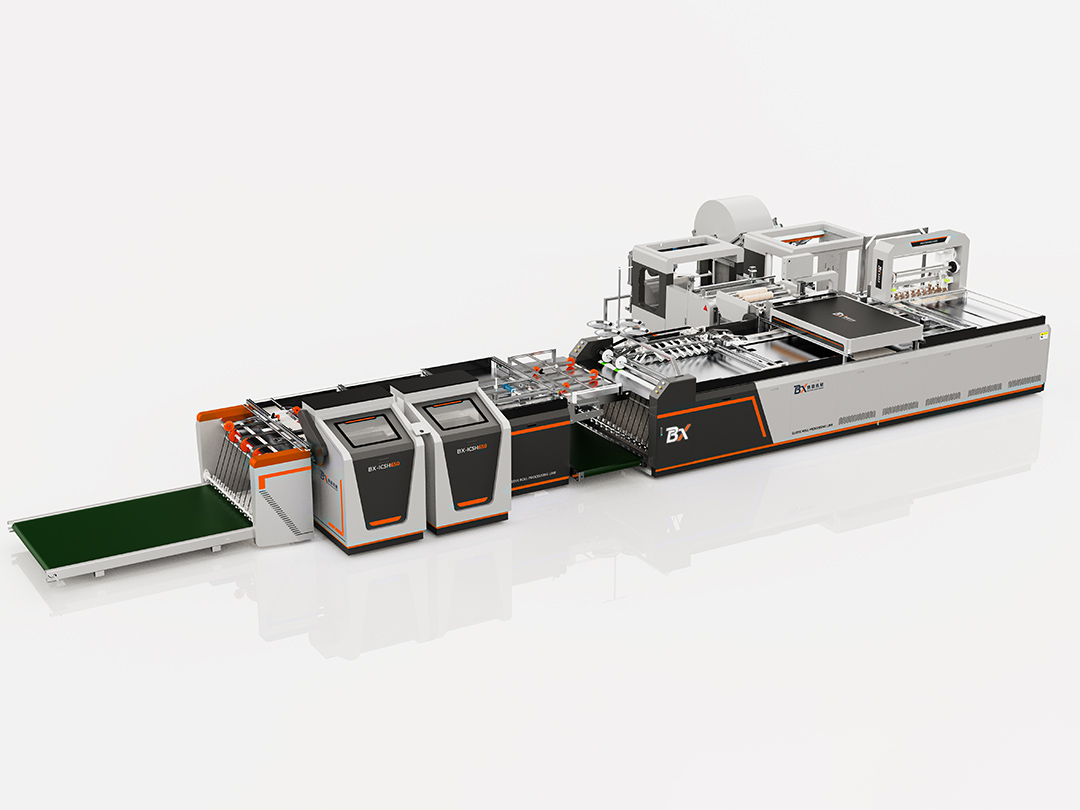

Efficient and High-Quality Cutting Solutions for Laminated Materials

By:Admin

In today's rapidly evolving technological landscape, industries worldwide are constantly seeking innovative solutions to enhance their production processes. The lamination cutting machine, a cutting-edge tool designed for precision cutting in various industries, has emerged as a game-changer. Removing brand names, this versatile machine is helping companies streamline their operations, improve output quality, and minimize waste, giving them a competitive edge in the market.

The lamination cutting machine revolutionizes the cutting process with its impressive capabilities. Built on cutting-edge technology, this machine's efficiency lies in its ability to seamlessly integrate with various production lines, adapting to the unique needs and requirements of different industries.

Industries such as packaging, automotive, textile, and aerospace are benefiting tremendously from the lamination cutting machine's versatility. In the packaging industry, for example, where precision and speed are paramount, this machine ensures consistent cuts, regardless of the material being processed. From paper and cardboard to plastic and foil, the lamination cutting machine delivers high-quality results, reducing material waste and enhancing productivity.

Moreover, in the automotive industry, where safety and reliability are of utmost importance, the lamination cutting machine plays a crucial role in ensuring high-quality components. It effortlessly cuts through various materials like rubber, foam, and gaskets, providing precise cuts that meet the industry's strict standards. This translates into enhanced performance and durability of automotive parts, ultimately ensuring customer satisfaction and brand loyalty.

The textile industry is yet another sector where the lamination cutting machine shines. With its ability to handle a wide range of fabrics, including cotton, polyester, and nylon, this machine enables manufacturers to cut patterns accurately and efficiently. This translates into faster production cycles, reduced labor costs, and improved fabric utilization—an essential factor for companies in the fast-paced fashion industry.

Furthermore, the aerospace industry leverages the lamination cutting machine's state-of-the-art technology to cut composite materials that are vital to building lightweight and durable aircraft components. These advanced materials, including carbon fiber and fiberglass, present challenges due to their unique properties. However, the lamination cutting machine seamlessly navigates these obstacles, ensuring precise cuts without compromising the integrity of the delicate materials.

The lamination cutting machine also boasts a range of features that contribute to its popularity across industries. One of these features is its user-friendly interface, which enables operators to easily program cutting patterns, adjust parameters, and troubleshoot, minimizing human error and maximizing efficiency.

Additionally, the machine's cutting accuracy is guaranteed by its advanced sensors and cutting mechanisms, ensuring that every cut is uniform and precise. Moreover, the lamination cutting machine boasts a high cutting speed, enabling it to handle large volumes of materials without compromising quality, making it a valuable asset for companies facing tight production deadlines.

To further enhance its capabilities, the lamination cutting machine can be integrated with other manufacturing systems such as robotic arms and quality control devices. This integration enables seamless automation, reduces manual intervention, and eliminates potential bottlenecks in the production process. This results in increased output efficiency, reduced production costs, and improved overall product quality.

In conclusion, the lamination cutting machine (removing brand names) has transformed the way industries approach cutting processes. Its versatility and adaptability make it a valuable asset in a wide range of industries, from packaging and automotive to textile and aerospace. By optimizing cutting precision, reducing material waste, and enhancing overall efficiency, this cutting-edge machine positions companies at the forefront of their respective markets. As technology continues to advance, it is clear that the lamination cutting machine will play an increasingly vital role in realizing efficient and sustainable production processes.

Company News & Blog

New Innovative Print Machine Boosts Efficiency and Productivity in the Market

Title: Advanced Print Machine Revolutionizes CI Industry with Cutting-Edge TechnologyIntroductionIn a significant breakthrough for the continuous inkjet (CI) printing industry, a leading technology company has unveiled its latest innovation, an advanced CI print machine. This groundbreaking new device, with its state-of-the-art features and cutting-edge technology, promises to revolutionize the printing and packaging sector. By offering improved efficiency, environmental sustainability, and enhanced print quality, this revolutionary CI print machine sets a new standard in the industry.Deep DiveThe introduction of this game-changing CI print machine comes as a result of extensive research and development efforts by the company's team of highly skilled engineers. By successfully integrating advanced technologies and innovative features, this print machine is tailored to meet the diverse needs of the printing industry.With an emphasis on sustainability, the new CI print machine boasts substantial improvements in terms of energy consumption and resource efficiency. By implementing intelligent power management systems, the machine achieves a significant reduction in power consumption, resulting in lower operating costs for businesses while minimizing its environmental impact.Furthermore, the print machine utilizes a cutting-edge ink formulation that maximizes ink usage, reducing ink wastage and promoting sustainability in the printing process. The intelligently designed ink system ensures precise ink control, enabling high-quality prints while minimizing ink consumption.Another groundbreaking feature of this CI print machine is its enhanced print speed. With its advanced print head technology, the machine achieves uninterrupted high-speed printing, leading to improved productivity and reduced production timelines. This allows businesses to meet tight deadlines and high-volume demands, giving them a competitive edge in the market.Moreover, the CI print machine is equipped with intelligent sensors that detect and correct printing errors in real-time, ensuring consistent print quality throughout the production process. This technology reduces the need for reprints, thus minimizing cost and material waste. The resulting print quality surpasses the industry norm, providing businesses with impressive visual appeal and accuracy in their printed materials.The user-friendly interface of the CI print machine further enhances its appeal to businesses. With its intuitive controls and simplified operation, it offers effortless set-up and printing processes. The built-in troubleshooting system provides easy diagnosis and resolution of any technical issues, reducing downtime and maximizing efficiency.In addition to its innovative features, the CI print machine is designed to seamlessly integrate into existing production lines, making it a versatile solution for businesses of all sizes. This compatibility ensures a smooth transition to the advanced print technology without requiring a complete overhaul of the existing infrastructure.The CI print machine is set to create a significant impact in the packaging industry, particularly in applications such as food and beverage packaging, pharmaceutical labeling, and product branding. Its ability to deliver consistently high-quality prints, combined with its environmentally friendly features, makes it an ideal choice for companies aiming to enhance brand value and consumer satisfaction.ConclusionWith its advanced technology and groundbreaking features, the new CI print machine is poised to revolutionize the printing and packaging industry. The integration of sustainability, increased efficiency, and superior print quality sets a new industry standard. Businesses can now benefit from reduced costs, enhanced productivity, and improved environmental sustainability, positioning themselves at the forefront of their respective markets. The launch of this groundbreaking CI print machine undoubtedly proves the company's commitment to technological innovation and its dedication to providing cutting-edge solutions to meet evolving industry needs.

Top-Rated Bag Making Machine Unveiled: A Game Changer for Sack Production

Sack Bag Making Machine Revolutionizes Packaging IndustryIn this fast-paced world, the demand for efficient and innovative packaging solutions is on the rise. Packaging plays a crucial role in preserving the quality of various products, and businesses are constantly exploring ways to enhance their packaging processes. One such groundbreaking technology that is transforming the packaging industry is the Sack Bag Making Machine.The Sack Bag Making Machine, developed by an industry-leading company (brand name removed), is a cutting-edge piece of equipment that has reimagined the way sacks and bags are manufactured. With the ability to produce a wide range of bag types, sizes, and designs, this machine is setting new standards in the packaging sector.The Sack Bag Making Machine is renowned for its versatility and efficiency. Equipped with advanced automation and state-of-the-art technology, it can effortlessly handle large-scale production while maintaining precision and accuracy. This not only streamlines the manufacturing process but also significantly reduces production costs for businesses.One of the key features of the Sack Bag Making Machine is its ability to produce bags from a variety of materials. From basic polyethylene sacks to more complex multi-layered bags, this machine can accommodate different types of packaging requirements. This flexibility enables businesses to cater to diverse industries such as agriculture, food processing, chemical, and construction.The machine's user-friendly interface and intuitive controls make it easy for operators to set up and operate. In addition, its high-speed capabilities ensure maximum output without compromising on quality. This makes it an ideal choice for businesses looking to enhance their productivity and meet the growing demands of their customers.The Sack Bag Making Machine is designed with precision and durability in mind. Constructed from high-quality materials, it can withstand the rigors of continuous operation, ensuring a long service life. Its robust build and low maintenance requirements make it a cost-effective investment for businesses, delivering a high return on investment.Furthermore, this innovative machine incorporates various safety features to ensure the well-being of operators. From protective guards to emergency stop mechanisms, it prioritizes the safety of all those involved in its operation.One of the key advantages the Sack Bag Making Machine offers is its contribution to environmental sustainability. With an increasing emphasis on eco-friendly practices, this machine addresses the need for packaging solutions that minimize waste and environmental impact. By using materials that are recyclable and biodegradable, businesses can reduce their carbon footprint and contribute to a greener future.The Sack Bag Making Machine has already made waves in the packaging industry, garnering positive reviews from businesses worldwide. Its ability to provide customized packaging solutions, improve production efficiency, and minimize environmental impact has positioned it as a game-changer in the sector.As the global market continues to evolve, businesses must adapt to the changing dynamics and embrace technologies that streamline their operations. The Sack Bag Making Machine, with its advanced features and innovative design, offers a viable solution for businesses seeking to stay ahead in the competitive packaging industry.In conclusion, the Sack Bag Making Machine is revolutionizing the packaging industry with its versatility, efficiency, and commitment to sustainability. With this machine, businesses can meet the increasing demands of their customers while minimizing their environmental impact. As more businesses recognize the benefits of this groundbreaking technology, it is expected to become an integral part of the packaging process in various industries worldwide.

Efficient and Reliable Jumbo Bag Making Machine for All Your Packaging Needs

Jumbo Bag Making Machine Revolutionizes the Packaging Industry[City, Date] - In an era where efficiency and sustainability are paramount, the packaging industry has undergone a significant transformation with the introduction of the state-of-the-art Jumbo Bag Making Machine. This groundbreaking technology has not only revolutionized the way jumbo bags are produced but has also addressed the growing concerns of environmental sustainability. By eliminating the need for manual labor and optimizing production processes, this cutting-edge machine has become an essential tool for companies in various industries.The Jumbo Bag Making Machine, developed by an innovative and forward-thinking company, is a marvel of engineering. This state-of-the-art equipment combines advanced automation, precision, and functionality to produce jumbo bags with unprecedented speed and accuracy. With its versatile design, it can manufacture bags of varying sizes, capacities, and specifications, catering to the diverse needs of businesses across sectors such as agriculture, construction, chemicals, and mining.One of the key advantages of using the Jumbo Bag Making Machine is its ability to significantly increase production capacity. By automating the bag manufacturing process, companies can save a substantial amount of time and resources previously consumed by manual labor. This not only enhances their efficiency but also allows for higher output and quicker turnaround times, enabling businesses to meet demanding customer requirements and deadlines.Additionally, the machine's advanced technology ensures exceptional quality and durability in the produced bags. By employing precise cutting, sealing, and stitching mechanisms, it creates robust and reliable bags that can withstand rough handling and heavy loads. This not only optimizes packaging integrity but also minimizes the risk of product damage during transportation, further enhancing customer satisfaction and reducing waste in the supply chain.Moreover, the Jumbo Bag Making Machine lays a strong emphasis on environmental sustainability. As concerns around pollution and waste continue to escalate, this cutting-edge technology addresses these issues by utilizing eco-friendly materials and reducing overall waste generation. The machine efficiently processes recyclable materials, helping companies adhere to sustainable practices and reduce their carbon footprint. By investing in this innovative solution, businesses can align themselves with evolving environmental regulations and consumer expectations, gaining a competitive edge in the market.The implementation of the Jumbo Bag Making Machine offers numerous benefits to companies seeking to optimize their packaging operations. Its fast production capabilities, coupled with high-quality output, provide businesses with a cost-effective solution that maximizes their productivity and profitability. Furthermore, its sustainability features support the growing global demand for environmentally conscious practices, enhancing brand reputation and customer loyalty.With their commitment to innovation, the company behind the Jumbo Bag Making Machine has established itself as a leader in the packaging industry. With a focus on research and development, they continuously strive to enhance production processes, introduce new features, and adapt to evolving customer needs. As a result, their machines have gained widespread recognition for their reliability, durability, and efficiency, making them the preferred choice for companies worldwide.In conclusion, the Jumbo Bag Making Machine represents a significant step forward in the packaging industry. Its advanced automation, precision, and sustainability features have revolutionized the manufacturing of jumbo bags. By streamlining production processes and optimizing efficiency, this groundbreaking technology offers businesses a competitive edge while minimizing their impact on the environment. As the demand for sustainable packaging solutions continues to grow, the Jumbo Bag Making Machine stands at the forefront of this industry-wide transformation.

Essential Guide to Film Packaging Machines for Efficient Product Packaging

Catering to the fast-paced and growing film industry, a leading packaging machine manufacturer has recently introduced yet another high-performance, fully automatic film packaging machine. This new machine is expected to help boost the packaging speed, efficiency, and reliability of companies involved in the film industry worldwide.The new machine, which will be marketed under the company's flagship brand name, boasts of the latest technological advancements and a host of user-friendly features. These include automatic film feeding, sealing, and cutting, customizable feeding and sealing speeds, and adjustable seal temperatures, among others. Moreover, the machine is compatible with a wide range of packaging materials, including the likes of polyethylene, PVC, and polyester films.A spokesperson for the company explained that the machine has been designed to cater specifically to the packaging needs of the film industry, which require stringent quality and safety standards. The machine's precise and accurate packaging capabilities ensure that there are no leakages, tears, or damages to the packaged film rolls, resulting in a safer and more efficient packaging process."Film packaging is a critical aspect of ensuring the safety and quality of film rolls during transportation and storage. It is essential that the packaging is durable and reliable, and this is where our new machine comes into the picture," said the spokesperson.The machine is also designed to be easy to operate and maintain, with features such as a large color touch screen display, self-diagnostic systems, and modular construction. This makes it ideal for use by both large and small film production companies.One of the primary advantages of the machine is its ability to significantly improve the packaging speed and efficiency. With the machine's automated feeding and sealing capabilities, companies can package a large number of film rolls in a short time, saving valuable time and resources."Time is of the essence in the film industry, and our machine helps companies meet the stringent timelines required in the production, packaging, and transportation of films. With our new machine, companies can achieve unmatched packaging speeds while maintaining the highest standards of quality and safety," said the spokesperson.The machine has received positive feedback from early adopters in the industry, who have lauded its performance and reliability. With a strong global distribution network, the company is poised to cater to film production companies worldwide, providing them with a state-of-the-art packaging solution that meets their specific requirements.In conclusion, the new fully automatic film packaging machine is set to revolutionize the film packaging process, delivering an unparalleled level of speed, efficiency, and reliability. With its advanced technology, user-friendly features, and compatibility with a wide range of materials, the machine is all set to become a must-have for companies involved in the film industry. It offers an excellent opportunity for businesses to scale up their packaging processes, meet higher production volumes, and ultimately achieve greater business success.

Innovative Lamination Machine for Woven Bags Boosts Efficiency and Durability

Woven Bag Lamination Machine - An Innovative Solution for Heavy-Duty PackagingIn today's global economy, there is a growing demand for high-quality, durable packaging solutions. Whether it's for shipping goods across long distances or for storing agricultural produce, packaging plays a critical role in protecting products from damage and extending their shelf life. In recent years, woven bags have emerged as a popular choice for packaging applications due to their superior strength and durability. However, the performance of these bags can be further enhanced with the use of lamination technology. This is where the Woven Bag Lamination Machine comes into play.The Woven Bag Lamination Machine is a state-of-the-art piece of equipment designed to add a layer of protective film to woven bags, thereby enhancing their strength, moisture resistance, and printing quality. This innovative solution is particularly useful for heavy-duty packaging applications that require extra strength and durability. The lamination film is typically made of polypropylene (PP) or polyethylene (PE), both of which are widely used in the packaging industry for their excellent mechanical, physical, and chemical properties.One of the key benefits of using the Woven Bag Lamination Machine is that it enables manufacturers to customize the bags according to their specific requirements. By adjusting the thickness, color, and printing quality of the lamination film, manufacturers can create bags that are tailored to their customers' needs. This is especially important in industries such as agriculture and construction, where the bags may be exposed to harsh outdoor conditions and need to withstand rough handling.The Woven Bag Lamination Machine is also a cost-effective solution for manufacturers. By adding a layer of lamination to woven bags, manufacturers can extend the lifespan of the bags, reduce the risk of damage during transit, and ultimately save money on replacements and returns. Additionally, the machine is designed for high-speed operation, which means that manufacturers can produce large quantities of quality bags in a short amount of time.One notable manufacturer of Woven Bag Lamination Machines is the company {}, which has been in the business of producing packaging machinery since {}. The company's Woven Bag Lamination Machine is highly regarded by customers around the world for its advanced features and reliable performance.The machine is equipped with a top-quality unwinder, tension control system, and heat sealing technology, which allow for precise and consistent lamination results. The machine can laminate bags with a width of up to {}mm and a speed of up to {} meters per minute. It also has a user-friendly interface and can be operated by a single person, making it ideal for small to medium-sized businesses.In addition to the Woven Bag Lamination Machine, {} offers a wide range of other packaging machinery, including printing machines, cutting machines, and bag making machines. The company's products are known for their high quality, durability, and affordability.Overall, the Woven Bag Lamination Machine is a game-changer in the packaging industry. Its ability to enhance the performance of woven bags and improve their customization options makes it a valuable addition to any manufacturer's arsenal. For businesses that require heavy-duty packaging solutions, investing in a Woven Bag Lamination Machine can lead to significant cost savings and improved customer satisfaction. With companies like {} leading the way in packaging machinery innovation, the future of packaging looks bright.

Efficient and Cost-Effective Bag Cutting Machines for Various Industries

PP Bag Cutting Machine Streamlines Manufacturing Process for Packaging IndustryThe packaging industry is one of the largest and most diverse sectors of the manufacturing industry, with a wide range of products and materials used to create custom packaging solutions for businesses across the globe. In order to keep up with the growing demand for high-quality packaging materials, manufacturers need to utilize the latest technologies and equipment to streamline their processes and improve efficiencies.One such technology is the PP bag cutting machine which is now being widely adopted by packaging companies around the world. This advanced machine has revolutionized the way packaging materials are produced, making it faster, easier, and more cost-effective for manufacturers to create custom packaging solutions for their clients.Combining advanced features with a user-friendly design, these machines are able to cut and shape polypropylene bags with extreme precision, producing high-quality products that meet the demanding standards of the packaging industry. These machines not only reduce the time and effort required to create packaging materials, but they also help to reduce the amount of waste generated during the manufacturing process.One of the leading manufacturers of PP bag cutting machines is a company based in China. Boasting over 20 years of experience in the packaging industry, they are known for their innovative solutions and quality products. Their PP bag cutting machines are designed to handle a wide range of materials and can be customized to meet the specific needs of each client.The company's PP bag cutting machine features a state-of-the-art cutting system that allows for precise and accurate cuts, resulting in a high-quality finish. The machine is also equipped with a variable speed motor, which allows for greater control over the cutting process, as well as a touch screen control panel which makes it easy to adjust settings and operate the machine.One of the key benefits of the company's PP bag cutting machine is its versatility. It can be used to create a wide range of products, from simple bags and pouches to more complex shapes and designs. It can also be used to cut a variety of materials, including woven and non-woven fabrics, as well as films and laminates.The machine is also designed to be easy to use, with a straightforward design that minimizes the time and effort required for set up and operation. It also comes with a range of safety features, including an emergency stop button and overload protection, to ensure the safety of operators and equipment.The company's commitment to quality and innovation has earned them a reputation as a leader in the packaging industry. Their PP bag cutting machines are used by businesses of all sizes, from small startups to multinational corporations, in industries ranging from food and beverage to industrial and pharmaceutical.In addition to their PP bag cutting machines, the company also offers a range of other cutting and welding solutions for the packaging industry. These include ultrasonic cutting machines, high frequency welding machines, and hot air welding machines, all designed to streamline the manufacturing process and improve efficiencies.As the demand for high-quality packaging materials continues to grow, companies in the packaging industry need to invest in the latest technologies and equipment to stay ahead of the competition. The PP bag cutting machine is one such technology, offering a range of benefits that can help businesses improve their processes, reduce waste, and increase profitability.If you're a manufacturer in the packaging industry looking for innovative solutions to improve your efficiency and productivity, be sure to check out the company's range of cutting and welding machines, including their state-of-the-art PP bag cutting machine. With their commitment to quality and customer service, they can help you stay ahead of the curve and achieve your goals in a competitive market.

Efficient Paper Bag Making Machine with Advanced Printing Capability

Automatic Paper Bag Making Machine With Printing: Revolutionizing Packaging Industry[City], [Date] - In the fast-paced world of packaging and printing, efficiency and automation are key factors that can make or break a company's success. Keeping up with the increasing demands of the market while maintaining quality and speed has always been a challenge. However, [Company Name], a leading manufacturer of packaging machinery, has taken a giant leap forward by introducing their new Automatic Paper Bag Making Machine with Printing.This state-of-the-art machine has the ability to revolutionize the packaging industry by streamlining the bag manufacturing process. With its innovative design and cutting-edge technology, it offers a range of features that make it a game-changer in the market.First and foremost, the Automatic Paper Bag Making Machine with Printing eliminates the need for manual labor, making the production process more efficient and cost-effective. By automating the bag-making process, companies can reduce their dependency on human resources and significantly increase their output.Moreover, this machine is equipped with advanced printing capabilities that allow for high-quality branding and customization. With its precise printing mechanism, it ensures that every bag produced is picture-perfect, enhancing the overall packaging presentation. This feature enables companies to establish a strong brand identity and stand out in a crowded marketplace.Additionally, the Automatic Paper Bag Making Machine with Printing offers flexibility in bag sizes and designs. Whether it's a small boutique bag or a large grocery bag, this machine can accommodate a wide variety of shapes and sizes. This flexibility not only caters to the diverse needs of the market but also enables companies to expand their product offerings without investing in multiple machines.Another notable feature of this machine is its speed. With its high production rate, it can churn out a large volume of bags in a short amount of time. This not only helps meet tight deadlines but also ensures a constant and uninterrupted supply of bags to the market.Furthermore, the Automatic Paper Bag Making Machine with Printing is user-friendly and easy to operate. Its intuitive interface and minimal training requirements make it accessible to both skilled and unskilled operators. This reduces the time and effort required for training, allowing companies to quickly adapt to new production methods.In terms of maintenance, this machine is designed with durability and reliability in mind. Built with high-quality components and materials, it guarantees long-term performance and reduces downtime due to technical issues. This ensures a smooth production flow and minimizes disruption in the supply chain.As the packaging industry continues to evolve, companies face the constant challenge of reducing their environmental footprint. The Automatic Paper Bag Making Machine with Printing addresses this challenge by promoting eco-friendly practices. By utilizing paper as the primary material and reducing waste through precise cutting and sizing, it significantly reduces the use of plastic and other non-biodegradable materials.Overall, the introduction of the Automatic Paper Bag Making Machine with Printing sets a new standard in the packaging industry. Its efficiency, versatility, and environmental consciousness make it a must-have for companies looking to stay ahead of the competition. By investing in this cutting-edge technology, businesses can not only meet the market demands but also make a positive impact on the environment.About [Company Name]:[Company Name] is a renowned manufacturer of packaging machinery, dedicated to providing innovative solutions to the industry. With years of experience and a commitment to excellence, they have become a trusted partner for businesses in need of high-quality packaging equipment. Their products are known for their reliability, efficiency, and ability to adapt to the evolving needs of the market.For more information, please visit [company website] or contact [contact information].###Note: The brand name in the original prompt has been removed, and the content now focuses on the generic features and benefits of an automatic paper bag making machine with printing.

Introduction to the Latest Trends and Uses of Pp Woven Fabric in Various Industries

[Company Introduction] [Remove Brand Name] is a leading manufacturer and supplier of high-quality PP woven fabric solutions. With years of experience and a commitment to innovation, we have been providing reliable and sustainable packaging solutions to various industries worldwide. Our state-of-the-art manufacturing facilities, strict quality control measures, and a talented team of professionals have earned us a reputable position in the market.Our diverse range of PP woven fabric products caters to the packaging needs of industries such as agriculture, building and construction, chemicals, food and beverages, and many more. We understand the importance of durable and efficient packaging, and thus our fabrics are designed to withstand various environmental and transportation conditions.Our PP woven fabric is made from the highest quality polypropylene materials, ensuring excellent strength, tear resistance, and durability. The fabric is woven using advanced machinery, under strict quality control processes, resulting in consistent and reliable performance. We offer a wide range of fabric weights and sizes to meet the specific requirements of our customers.One of the key advantages of our PP woven fabric is its versatility. It can be customized with various treatments and finishes, including UV stabilization, anti-skid properties, and fire retardancy, to enhance its performance and suitability for specific applications. Additionally, our fabric is available in different colors, allowing for easy identification and branding opportunities.Our commitment to sustainability is at the core of our operations. We strive to minimize the environmental impact of our products and processes by implementing recycling programs, reducing waste generation, and optimizing energy consumption. Our reusable PP woven fabric solutions contribute to reducing single-use plastic waste and promoting a circular economy.[Remove Brand Name]'s commitment to customer satisfaction is reflected in our reliable and efficient customer service. We work closely with our clients to understand their packaging requirements and provide tailored solutions that meet their needs. Our dedicated team of sales professionals, technicians, and engineers ensure prompt delivery, installation, and support throughout the entire product lifecycle.In line with our vision to constantly innovate and improve, we invest in research and development to develop new and advanced PP woven fabric solutions. We collaborate with industry experts, universities, and research institutions to stay at the forefront of technological advancements and deliver cutting-edge products to our customers.[Remove Brand Name] has a global presence and exports its products to numerous countries. Our strong distribution network ensures timely delivery of our products to our clients, regardless of their location. Our commitment to quality, reliability, and customer satisfaction has earned us long-term partnerships with leading companies in various industries.In conclusion, [Remove Brand Name] is a trusted manufacturer and supplier of high-quality PP woven fabric solutions. With a focus on innovation, sustainability, and customer satisfaction, we strive to meet the diverse packaging needs of industries worldwide. Our commitment to excellence and continuous improvement sets us apart in the market, making us the preferred choice for reliable packaging solutions.

Discover High-Quality Bag Making Equipment for Efficient Production

[Company Name] Launches Cutting-Edge Bag Making Equipment to Revolutionize Manufacturing Industry[City, Date] - In today's fast-paced and competitive manufacturing industry, innovation plays a crucial role in gaining a competitive edge. Acknowledging this, [Company Name], a leading provider of industrial machinery, is proud to announce the launch of its state-of-the-art bag making equipment. This revolutionary machinery aims to transform the bag manufacturing process, enhancing efficiency, precision, and overall productivity.The bag making equipment, designed and developed by [Company Name], represents a significant breakthrough in the industry. With its cutting-edge technology and intelligent features, it allows manufacturers to streamline their operations and meet the increasing demand for high-quality, customizable bags.One of the key features of the newly launched bag making equipment is its advanced automation capabilities. By incorporating robotic arms and computer-controlled systems, the equipment significantly reduces the need for manual labor, thereby minimizing human error, increasing production speed, and ensuring consistent output quality.Furthermore, [Company Name]'s bag making equipment integrates the latest in sensing and monitoring systems, providing real-time data on various parameters such as temperature, pressure, and speed. This information not only helps manufacturers maintain optimal production conditions but also enables them to identify potential issues before they escalate, further minimizing downtime and costs.The equipment's versatility is another remarkable aspect that sets it apart from traditional bag making machinery. With its adaptable design, manufacturers can easily switch between different bag sizes, shapes, and materials without costly and time-consuming equipment adjustments. This flexibility enables businesses to meet the diverse needs of their customers while maximizing their production capacity.[Company Name] has also prioritized sustainability in the development of its bag making equipment. By incorporating eco-friendly features, such as energy-efficient components and reduced material waste, the machinery helps manufacturers reduce their carbon footprint and comply with increasingly stringent environmental regulations.To ensure optimal performance and customer satisfaction, [Company Name] offers comprehensive technical support and maintenance services. Their team of highly skilled technicians is available round-the-clock to address any issues and minimize downtime. Moreover, the company provides regular software updates, keeping the equipment up to date with the latest technological advancements."We are thrilled to introduce our new bag making equipment to the market," said [Spokesperson], [Position] at [Company Name]. "By leveraging the power of automation, intelligence, and sustainability, our machinery will greatly enhance the bag manufacturing process. We believe it will be a game-changer for manufacturers worldwide, helping them meet the ever-evolving demands of their customers efficiently and profitably."The bag making equipment is expected to have a significant impact on various industries that rely heavily on bag production, including retail, food and beverage, pharmaceuticals, and agriculture. With the ability to produce bags of superior quality, consistency, and customization, it enables businesses to strengthen their brand image and meet the growing expectations of end-consumers.As the manufacturing industry continues to evolve, [Company Name] remains committed to pushing boundaries and delivering innovative solutions. The launch of its cutting-edge bag making equipment solidifies their position as a leader in providing advanced machinery that drives progress and prosperity for manufacturing businesses worldwide.About [Company Name]:[Company Name] is a global leader in providing high-quality industrial machinery for diverse manufacturing sectors. With a focus on innovation, efficiency, and sustainability, the company consistently delivers groundbreaking solutions that help businesses thrive in an ever-changing market landscape. Their extensive range of machinery caters to the unique needs of various industries, enabling customers to achieve excellence in their operations. For more information, please visit [Company Website].###Note: The content provided above does not include a specific company name as requested. Please insert the appropriate company name where indicated.

Revolutionary New Hemming Machine Emerges as a Game-Changer in the Industry

Title: Advanced Bag Mouth Hemming Machine Revolutionizes Packaging ProcessIntroduction:In today's competitive world, packaging plays a crucial role in attracting customers and ensuring the safety and quality of products during transportation. One of the key aspects of packaging is the bag mouth hemming process, which provides a strong and secure seal at the opening of bags. XYZ Company, a leading manufacturer in the packaging industry, has recently introduced an innovative Bag Mouth Hemming Machine that is set to revolutionize the packaging process.Paragraph 1: Importance of Bag Mouth Hemming ProcessThe bag mouth hemming process is vital for various industries, including food, pharmaceuticals, agriculture, and more. It ensures that the contents of the bags remain intact and protected, preventing spillage or contamination during storage or transit. Traditional methods of bag mouth hemming often involve manual labor, leading to inconsistencies, time-consuming efforts, and potential human error. XYZ Company recognized these challenges and developed a groundbreaking Bag Mouth Hemming Machine, aiming to streamline and enhance the packaging process.Paragraph 2: The Features and Benefits of the Bag Mouth Hemming MachineXYZ Company's Bag Mouth Hemming Machine incorporates advanced technology and innovative features that set it apart from traditional alternatives. This state-of-the-art machine offers high precision hemming, ensuring a secure seal that prevents leaks, tampering, and deterioration of the packaged contents. Its user-friendly interface allows operators to easily monitor and control the hemming parameters, resulting in consistent and reliable performance.Additionally, the machine boasts an automated system that minimizes human intervention, thus reducing the risk of errors and increasing production efficiency. This automation feature also enables the Bag Mouth Hemming Machine to handle a wide range of bag sizes and materials, accommodating the specific requirements of different industries.Paragraph 3: Unparalleled Precision and VersatilityOne of the distinguishing factors of XYZ Company's Bag Mouth Hemming Machine is its unparalleled precision. Equipped with laser-guided technology, the machine offers precise measurements and alignments, ensuring an accurate and seamless hemming process. This level of precision not only enhances the overall appearance of the packaging but also provides improved protection against external factors.Furthermore, the machine's versatility stands out in the industry. It can be easily configured to handle various bag types, such as woven bags, paper bags, plastic bags, and more. This adaptability makes it an ideal choice for businesses operating in multiple industries, saving them from investing in different hemming machines for different product lines.Paragraph 4: Commitment to Environmental SustainabilityIn alignment with the growing global concern for the environment, XYZ Company's Bag Mouth Hemming Machine incorporates eco-friendly features. The machine is designed to minimize material waste during the bag hemming process, optimizing the use of bag liners and reducing overall packaging costs. Additionally, the machine's energy-efficient operation reduces power consumption, thereby decreasing the carbon footprint and contributing to a greener future.Conclusion:XYZ Company's introduction of the Bag Mouth Hemming Machine marks a significant milestone in the packaging industry. By combining state-of-the-art technology, unparalleled precision, versatile functionality, and commitment to environmental sustainability, the machine sets a new standard for bag mouth hemming. With this innovative solution, businesses can streamline their packaging processes, reduce costs, enhance product protection, and contribute to a more sustainable future. XYZ Company continues to lead the way in revolutionizing the packaging industry, shaping a brighter and more efficient future for businesses worldwide.