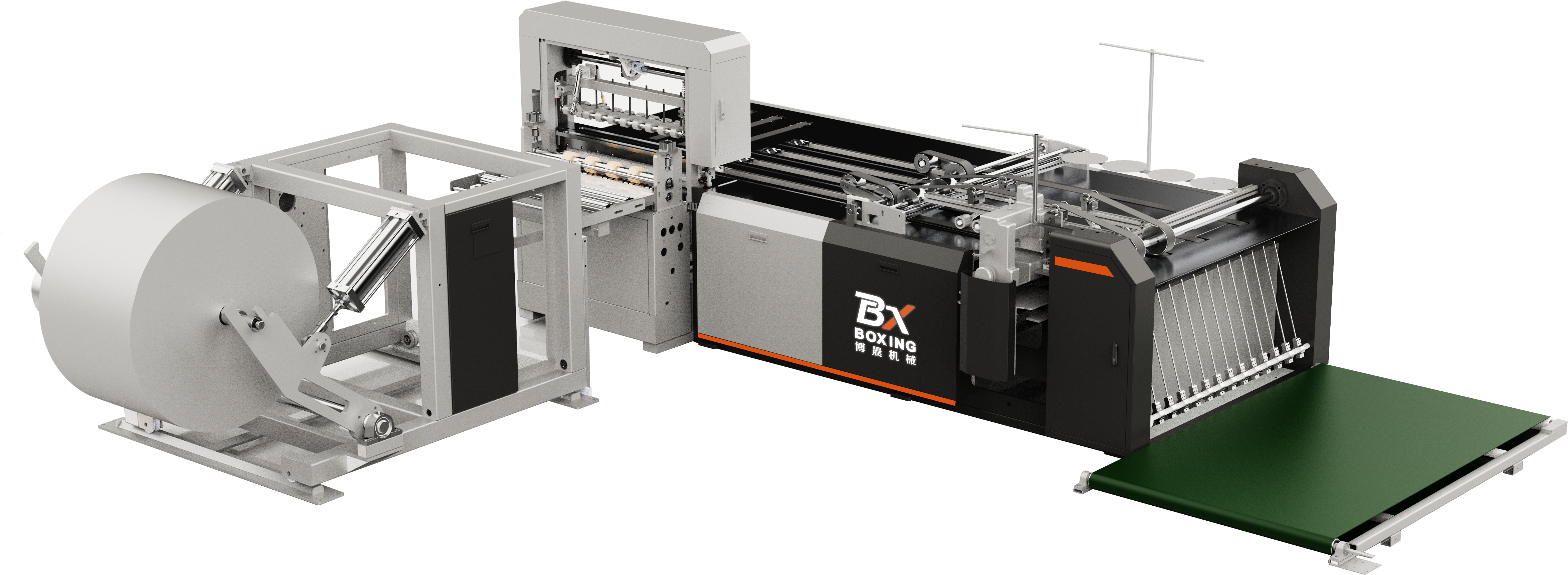

This unit uses PP or PE as the raw material, and uses the salivation process and PP Woven Fabric to perform Single Side/Double Side Lamination. The entire process flow of the unit, from Fabric Under, Lamination, and Rewider, is equipped with advanced electrical and mechanical devices to achieve single control and group control linkage. The Two Section Player uses EPC Control to perform EPC control on the fabric, and uses brakes to perform Tension Control on the fabric to achieve Automatic Roller; Before laminating, a preheating roller is installed to preheat and dry the fabric. Lamination, silica gel, pressing roller, etc. adopt a double interlayer forced water cooling circulation structure, which has a good cooling effect; Rewider adopts two section stable tension surface friction Rewider and pneumatic cross cutting to achieve non-stop Roller Change. It is equipped with a waste edge cutting, edge blowing mechanism, and product length counting device. The clutch of each roller of the entire machine is controlled pneumatically.

1) The adhesive shall be firm without obvious peeling. When the coating uses the same type of fabric as PP Woven Fabric, the adhesive peel resistance shall not be less than 3N/30mm.

2) The entire width of the fabric shall be fully coated without obvious horizontal lines or holidays, and the width of the coating side shall not be greater than 5mm.

3) Laminated layers have uniform thickness and consistent color, without bubbles, black spots, streaks, and hard lumps.

4) Rewider is neat, with a deviation of ± 5mm, and consistent tightness.

The fabric surface is clean and free from impurities.After more than 20 years of production practice, this Lamination machine has continuously improved and innovated its models, featuring advanced technology, stable quality, convenient operation, and high degree of automation. It is widely used in the packaging, storage, and transportation of chemical, petrochemical, cement, metallurgy, and mineral industries.

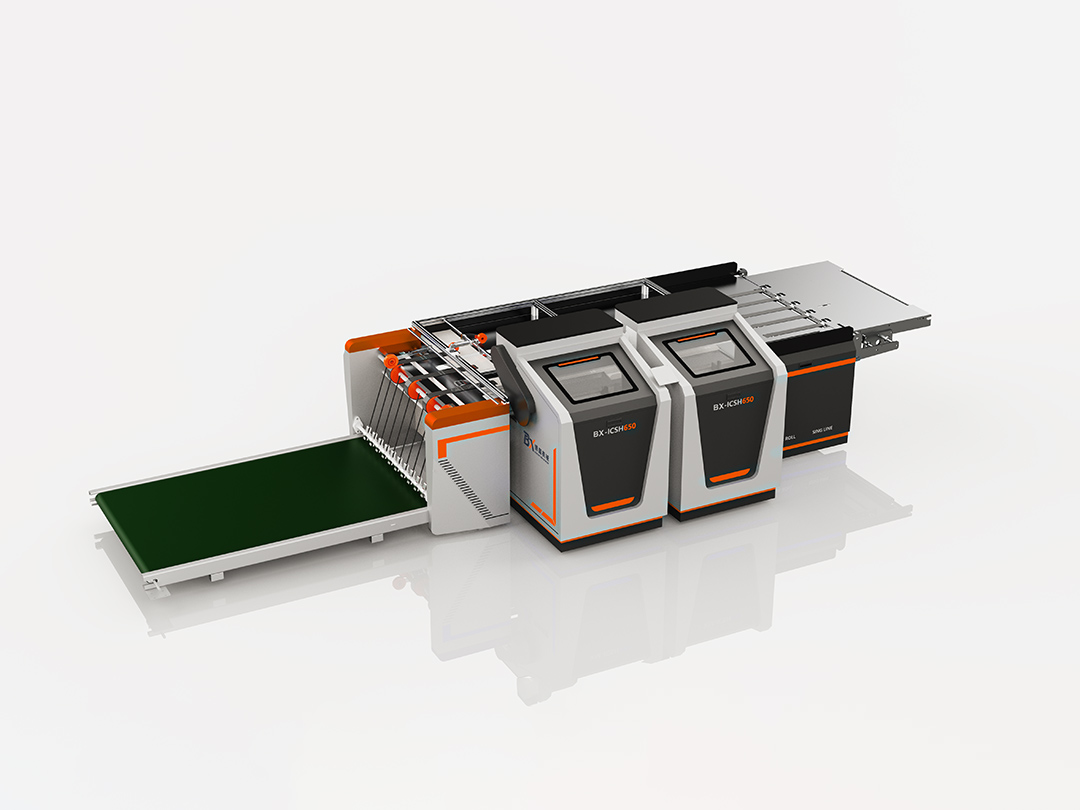

| Width of Lamination | 300-650mm |

| Thickness of Lamination | 6-60um |

| Speed | 20-200 m/min |

| Screw diameter × Length-diameter ratio | Φ75*33mm |

| Roll length | 800mm |

| Roll Speed /Min | 80rpm |

| Max Extrusion | 230(115*2)kg |

| Length of T-shaped Die Mouth | 950mm |

| Max Unwider Diameter | 1300mm |

| Max Rewider Diameter | 1300mm |

| Power Rate | 120kw |

| Air Consumption | 0.6m³/min |

| Cooling Water | 0.5³/min |

| Weight | 26Ton |

| Measurement | 16*55*2.5m |