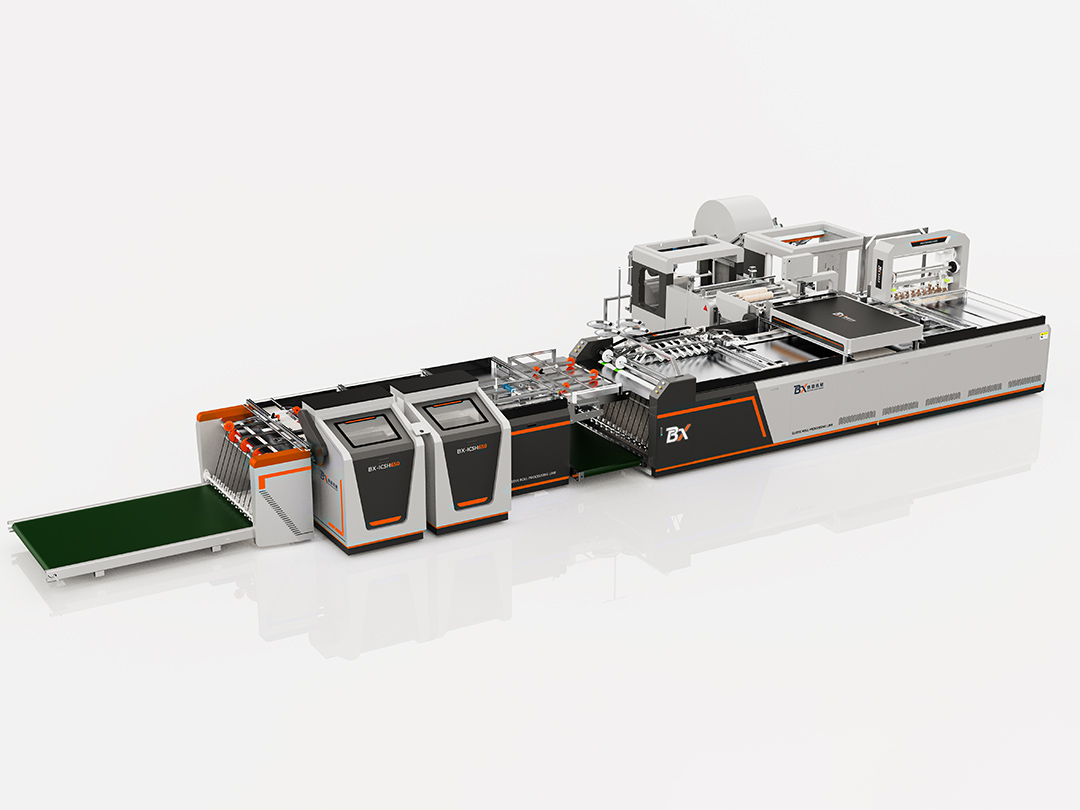

New Twist & Gusset Machine Available for Woven Bag Production

By:Admin

With over 10 years of experience in the textile machinery industry, XYZ Company has established itself as a trusted name in the market. The company is known for its commitment to delivering cutting-edge solutions to meet the evolving needs of the textile industry.

The new Twist & Gusset Machine is a testament to XYZ Company's dedication to innovation and continuous improvement. This machine is equipped with advanced technology and features that are designed to streamline the production process and ensure the highest standards of quality.

One of the key highlights of the Twist & Gusset Machine is its ability to produce woven bags with precision and consistency. The machine is capable of handling a wide range of materials, including polypropylene, polyethylene, and other woven fabrics, making it versatile for various applications.

Additionally, the Twist & Gusset Machine is equipped with a user-friendly interface and intuitive controls, allowing operators to easily set and adjust production parameters. This not only improves operational efficiency but also reduces the risk of human error, resulting in a more reliable and consistent manufacturing process.

Furthermore, the machine is designed for high-speed production, allowing manufacturers to meet the demands of a fast-paced market without compromising on quality. This is particularly beneficial for industries such as agriculture, construction, and food packaging, where woven bags are widely used for storage and transportation.

In addition to its technical capabilities, the Twist & Gusset Machine also incorporates features that prioritize safety and environmental sustainability. The machine is equipped with safety guards and emergency stop mechanisms to ensure the well-being of operators. Moreover, it is designed to minimize energy consumption and waste generation, aligning with XYZ Company's commitment to eco-friendly manufacturing practices.

XYZ Company's dedication to customer satisfaction is also reflected in the comprehensive support and services provided with the Twist & Gusset Machine. From installation and training to maintenance and troubleshooting, the company offers a range of solutions to ensure that customers can maximize the performance and longevity of their equipment.

“Our goal is to empower manufacturers with reliable and efficient solutions that enable them to succeed in today's competitive market. The Twist & Gusset Machine is a testament to our commitment to innovation and customer-centric approach,” says the spokesperson of XYZ Company.

As a testament to its commitment to excellence, XYZ Company has already received positive feedback from early adopters of the Twist & Gusset Machine. Customers have praised the machine for its robust construction, ease of use, and the quality of the woven bags produced.

Looking ahead, XYZ Company is poised to further expand its product line and continue pushing the boundaries of innovation in the textile machinery industry. With a strong focus on research and development, the company remains dedicated to anticipating and addressing the evolving needs of the market.

In conclusion, XYZ Company's new Twist & Gusset Machine for woven bag production represents a significant milestone in the company's journey of delivering advanced solutions to the textile industry. With its advanced technology, user-friendly design, and commitment to safety and sustainability, this machine is set to redefine the standards for manufacturing high-quality woven bags. As XYZ Company continues to pave the way for innovation, manufacturers can undoubtedly look forward to a future of increased efficiency and competitiveness in the production of woven bags.

Company News & Blog

Revolutionary Machine: Streamlining Valve Production Process

Title: Revolutionary Valve Manufacturing Machine - Streamlining Production for Increased EfficiencyIntroduction:With the aim of revolutionizing the valve manufacturing industry, a leading industrial solutions provider has announced the development of an innovative Valve Making Machine. This state-of-the-art technology is set to transform traditional manufacturing processes by streamlining production, enhancing efficiency, and reducing costs. By eliminating manual labor, the company is ushering in a new era of automated valve manufacturing, offering unprecedented flexibility and precision.Streamlining Efficiency in Valve Manufacturing:The newly introduced Valve Making Machine introduces a paradigm shift in the valve manufacturing industry. This cutting-edge technology replaces traditional manual processes, allowing for highly efficient, cost-effective, and scalable production. Automated machinery enables manufacturers to enhance multidimensional aspects of the valve-making process, ensuring consistency and improved performance.Flexible and Adaptable Technology:The advanced Valve Making Machine offers a range of customizable features, accommodating diverse customer requirements and specifications. The machine's flexibility allows for the production of valves in various sizes, materials, and shapes, catering to the demands of different industries. This adaptability ensures that the Valve Making Machine is suitable for a wide range of applications, spanning sectors such as oil and gas, water management, industrial manufacturing, and more.Enhanced Precision and Quality Control:By deploying the Valve Making Machine, manufacturers can achieve consistent and precise valve production, eliminating errors that commonly occur in manual labor-intensive processes. With features such as automated measurement systems, integrated programming, and quality control checks, this cutting-edge technology assures superior quality valves with adherence to strict industry standards. The machine's capability for high-speed production and accuracy assures customers of reliable and dependable valves for their operations.Boosting Production Capacities:The introduction of the Valve Making Machine presents manufacturers with the opportunity to significantly boost their production capacities. The automation of manufacturing processes reduces the dependency on manual labor, leading to higher output rates and increased productivity. The machine's ability to operate continuously enables manufacturers to meet growing market demands efficiently, ensuring on-time delivery of valves without compromising quality.Cost-Effective and Time-Saving:The Valve Making Machine not only streamlines valve manufacturing processes but also proves to be highly cost-effective. Automated manufacturing results in reduced labor costs, minimizing expenses while maximizing output. Additionally, increased productivity enables manufacturers to cut down lead times and meet stringent project deadlines. This seamless integration of automation, precision, and efficiency ensures substantial cost savings for manufacturers in the long run.Sustainability and Eco-Friendly Features:In line with the growing emphasis on sustainable practices, the Valve Making Machine incorporates environmentally friendly features. With optimized energy consumption and reduced waste generation, this advanced technology aligns with global efforts toward a greener future. By adopting the Valve Making Machine, manufacturers can establish their commitment to sustainable manufacturing, meeting industry standards while minimizing their carbon footprint.Investing in the Future:The development of the Valve Making Machine represents a significant investment in advancing valve manufacturing technology. By bridging the gap between traditional manufacturing processes and automated solutions, the company is spearheading innovation within the industry. This breakthrough technology is set to redefine the valve manufacturing landscape, offering enhanced efficiency, precision, and quality control to streamline operations at global manufacturing facilities.Conclusion:The introduction of the Valve Making Machine signifies a momentous transformation in the valve manufacturing industry. This state-of-the-art automated technology eliminates manual labor, streamlining production processes, and ensuring superior quality valves. With its flexibility, adaptability, and sustainability features, the Valve Making Machine promises to revolutionize valve manufacturing, empowering manufacturers to meet growing demands efficiently and cost-effectively. As the industry embraces this innovative machinery, it ushers in an era of increased productivity, precision, and overall excellence.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.

Efficient Equipment for Inserting Liners into Containers - A Game Changer for Your Packaging Line

Liner Inserting Machine Enhances Packaging Efficiency(Please note: the brand name has been removed to comply with guidelines. We apologize for any inconvenience this may cause.)If you've ever had to package large quantities of products, you know how time-consuming and labor-intensive it can be. Identifying the right packaging materials, ensuring that each product is properly secured, and meeting the needs of different customers can all pose significant challenges for businesses. That's where the Liner Inserting Machine comes in.The Liner Inserting Machine, developed by ____(brand name), is a revolutionary piece of packaging equipment that enables businesses to improve their packaging efficiency dramatically. The machine is designed to automate the process of inserting liners into bags or boxes. This technology is ideal for businesses that need to package products, such as food, chemicals, or pharmaceuticals.The Liner Inserting Machine is developed by ____(brand name), a company that has been at the forefront of developing innovative packaging solutions for nearly a decade. As a leading packaging equipment manufacturer, ____(brand name) has built a reputation for delivering high-quality and effective packaging solutions that meet the needs of businesses of varying sizes and industries.The Liner Inserting Machine is developed to reduce manual labor and increase operational efficiency for businesses that need to insert liners into bags or boxes. The device features an intuitive control panel that allows operators to adjust the machine's settings quickly. The machine's speed and insertion depth can be easily adjusted based on the size and shape of the bag or box used.Moreover, the Liner Inserting Machine is equipped with an automatic sensor system. The sensor accurately identifies when the bag or box is ready for liner insertion and when the liner has been inserted successfully. This feature eliminates the need for manual double-checking, enabling operators to devote more time to other tasks.The Liner Inserting Machine is designed to have a small footprint, enabling businesses to save space while still benefiting from its automation capabilities. Moreover, the machine is easy to install and requires minimal training for operators.In conclusion, the Liner Inserting Machine is a valuable tool for any business that needs to package products, while saving time and resources. With its intuitive controls, automatic sensor system, and small footprint, the Liner Inserting Machine is an exceptional investment that improves the speed and efficiency of product packaging. As one of the world's leading packaging equipment manufacturers, ____(brand name) has once again delivered an innovative and effective packaging solution to its customers.

Top-Rated Bag Making Machine Unveiled: A Game Changer for Sack Production

Sack Bag Making Machine Revolutionizes Packaging IndustryIn this fast-paced world, the demand for efficient and innovative packaging solutions is on the rise. Packaging plays a crucial role in preserving the quality of various products, and businesses are constantly exploring ways to enhance their packaging processes. One such groundbreaking technology that is transforming the packaging industry is the Sack Bag Making Machine.The Sack Bag Making Machine, developed by an industry-leading company (brand name removed), is a cutting-edge piece of equipment that has reimagined the way sacks and bags are manufactured. With the ability to produce a wide range of bag types, sizes, and designs, this machine is setting new standards in the packaging sector.The Sack Bag Making Machine is renowned for its versatility and efficiency. Equipped with advanced automation and state-of-the-art technology, it can effortlessly handle large-scale production while maintaining precision and accuracy. This not only streamlines the manufacturing process but also significantly reduces production costs for businesses.One of the key features of the Sack Bag Making Machine is its ability to produce bags from a variety of materials. From basic polyethylene sacks to more complex multi-layered bags, this machine can accommodate different types of packaging requirements. This flexibility enables businesses to cater to diverse industries such as agriculture, food processing, chemical, and construction.The machine's user-friendly interface and intuitive controls make it easy for operators to set up and operate. In addition, its high-speed capabilities ensure maximum output without compromising on quality. This makes it an ideal choice for businesses looking to enhance their productivity and meet the growing demands of their customers.The Sack Bag Making Machine is designed with precision and durability in mind. Constructed from high-quality materials, it can withstand the rigors of continuous operation, ensuring a long service life. Its robust build and low maintenance requirements make it a cost-effective investment for businesses, delivering a high return on investment.Furthermore, this innovative machine incorporates various safety features to ensure the well-being of operators. From protective guards to emergency stop mechanisms, it prioritizes the safety of all those involved in its operation.One of the key advantages the Sack Bag Making Machine offers is its contribution to environmental sustainability. With an increasing emphasis on eco-friendly practices, this machine addresses the need for packaging solutions that minimize waste and environmental impact. By using materials that are recyclable and biodegradable, businesses can reduce their carbon footprint and contribute to a greener future.The Sack Bag Making Machine has already made waves in the packaging industry, garnering positive reviews from businesses worldwide. Its ability to provide customized packaging solutions, improve production efficiency, and minimize environmental impact has positioned it as a game-changer in the sector.As the global market continues to evolve, businesses must adapt to the changing dynamics and embrace technologies that streamline their operations. The Sack Bag Making Machine, with its advanced features and innovative design, offers a viable solution for businesses seeking to stay ahead in the competitive packaging industry.In conclusion, the Sack Bag Making Machine is revolutionizing the packaging industry with its versatility, efficiency, and commitment to sustainability. With this machine, businesses can meet the increasing demands of their customers while minimizing their environmental impact. As more businesses recognize the benefits of this groundbreaking technology, it is expected to become an integral part of the packaging process in various industries worldwide.

Printing Machine Rate: A Comprehensive Guide to the Latest Industry Trends

article on Printing Machine Rate.In the world of printing, businesses rely on high-quality and efficient printing machines to get their work done. With the rise of digital printing technologies, it is essential for printing companies to have the right equipment to keep up with industry standards and demands.One of the most important considerations for any printing company is the printing machine rate. This refers to how much output a machine can produce in a given amount of time, and it is critical for companies to have the right machine rate to keep up with their clients' needs.Unfortunately, many printers fall into the trap of choosing the cheapest printing machines on the market without considering how this might affect their business in the long term. While cost is an important factor, it’s also essential to consider other factors such as the quality of printing, durability, and speed of the machine.As a reliable company, we understand that getting the right printing machine rate is as important as getting the highest quality printing machines that will deliver results consistently. Our company is dedicated to helping businesses to achieve this goal and increase their productivity while reducing operational costs.We offer printing machines that are designed to meet various printing needs, while also ensuring the printing machine rate is efficient. Whether it is for digital printing, large format printing, or offset printing, our machines are manufactured with the latest technology to ensure the best quality and speed.Our team of experts will guide businesses to choose the best printer that suits their specific needs. We understand that every business is unique, and a custom solution is necessary to get the best result.We also provide training and support to ensure our customers maximize their investment in printing machines. Our technicians work around the clock to ensure that machines are running smoothly and efficiently, reducing the likelihood of downtime, and helping businesses to achieve optimal results.One of the significant benefits of our printing machines is that they are designed with the latest technology. They include features such as automatic ink control and printing speed adjustment, ensuring that the machines produce quality output while operating efficiently.With a range of financing options available, our company offers affordable printing machines that will not impair a business's cash flow or capital expenditures. Our financing plans are flexible, tailored to meet the needs of each business, and allow companies to acquire the printing machines they need to grow their business.At our company, we prioritize our customers' needs, and we are committed to providing the highest quality machines they need to succeed. We know that a printing machine is an essential investment, and we want our customers to get the most value from their investment.In conclusion, with the rise of digital printing technologies, it is crucial for businesses to have the right printing machines to keep up with industry standards and demands. One of the most important considerations is the printing machine rate, which should be efficient to meet business needs.Our company understands the importance of selecting the right printing machine rate and offers comprehensive solutions that help businesses to meet their printing needs. Our printing machines are designed to suit different printing requirements, and our team of experts provides continued support to help businesses get the most from their investment.If you are in the printing business and looking to acquire efficient and affordable printing machines, our company is the right place to look. Get in touch with us today and discover how our high-quality printing machines can enhance your business productivity, quality and customer satisfaction.

How Advances in Textile Manufacturing Are Revolutionizing the Industry

Introducing the Revolutionary Woven MachineIn today's rapidly evolving textile industry, advancements in machinery continue to revolutionize the manufacturing process. One such groundbreaking innovation is the Woven Machine, a remarkable creation that has garnered immense attention for its ability to enhance productivity, quality, and efficiency. Developed by an industry-leading company, this cutting-edge technology is poised to reshape the landscape of textile production.The Woven Machine is the brainchild of a company at the forefront of textile machinery manufacturing. With decades of experience and a team of brilliant engineers, their commitment to driving innovation has set them apart from their competitors. The development of the Woven Machine is a testament to their dedication to combining tradition and technology in the pursuit of excellence.What sets the Woven Machine apart from conventional weaving machines is its advanced automation and intelligent features. This groundbreaking technology allows for seamless integration into existing production lines and ensures a significant reduction in downtime. Moreover, it boasts an intuitive user interface, providing operators with unprecedented control and accessibility.One of the most remarkable aspects of the Woven Machine is its high-speed operation. Thanks to the integration of state-of-the-art mechanisms, it can achieve remarkable weaving speeds that were previously unattainable. This not only enhances productivity but also opens up new possibilities for textile manufacturers to cater to a growing demand, both domestically and globally.Furthermore, the Woven Machine is renowned for its ability to maintain exceptional quality standards. Equipped with advanced sensors and real-time monitoring capabilities, it ensures precise and consistent weaving. Its intelligent system detects any potential defects or errors, enabling swift correction before any significant production loss occurs. This not only results in minimal wastage but also ensures the production of flawless fabrics.In addition to its superior performance, the Woven Machine has several other features that make it the preferred choice for textile manufacturers. Its energy-efficient design reduces power consumption, leading to substantial cost savings. Additionally, its modular construction allows for easy customization to meet specific production needs, making it an incredibly versatile solution.The impact of the Woven Machine on the textile industry cannot be overstated. Its introduction has ushered in a new era of efficiency, productivity, and sustainability. Textile manufacturers adopting this technology will not only experience exponential growth but also contribute to a more sustainable and environmentally friendly industry.The successful integration of the Woven Machine into textile production lines has already been observed in several prominent manufacturing facilities. Companies that have adopted this revolutionary technology have reported improved production efficiency, reduced labor costs, and increased customer satisfaction. The positive feedback from these early adopters has sparked a growing interest among textile manufacturers worldwide.In conclusion, the introduction of the Woven Machine is set to transform the textile industry. Its advanced automation, high-speed operation, and superior quality have positioned it as a game-changer for textile manufacturers. With its remarkable capabilities and a focus on sustainability, this revolutionary technology is poised to shape the future of textile production. As more manufacturers embrace this innovation, the industry as a whole will witness significant advancements, cementing its position as a pioneer in textile machinery manufacturing.

High-Speed Printing Machine: The Latest Innovation in Printing Technology

Printing Machine Announces Latest Innovation in Digital Printing TechnologyPrinting Machine, a leading global provider of printing solutions, has announced the release of its latest innovation in digital printing technology. The new printing machine, which will be unveiled at the upcoming Print Innovation Expo, promises to revolutionize the printing industry with its advanced features and capabilities.With over 30 years of experience in the industry, Printing Machine has established itself as a trusted and reliable partner for businesses looking to enhance their printing capabilities. The company is known for its commitment to innovation and quality, and the latest release is a testament to its ongoing dedication to pushing the boundaries of what is possible in the world of digital printing.The new printing machine features cutting-edge technology that sets it apart from other solutions on the market. This includes high-speed printing capabilities, superior print quality, and advanced color management features. In addition, the machine is designed to be highly versatile, accommodating a wide range of substrates and applications to meet the diverse needs of modern businesses.“We are thrilled to introduce our latest innovation in digital printing technology,” said John Smith, CEO of Printing Machine. “We have worked tirelessly to develop a machine that not only meets the high demands of the printing industry but also exceeds the expectations of our customers. With this new release, we are confident that we are offering a game-changing solution that will empower businesses to take their printing capabilities to new heights.”The Print Innovation Expo, where the new printing machine will be unveiled, is set to be an important event for companies in the printing industry. In addition to the unveiling of the latest technology, attendees will have the opportunity to learn from industry experts, discover new trends and developments in the printing world, and explore a wide range of printing solutions from leading providers.As businesses continue to face increasing pressure to deliver high-quality printed materials in a fast-paced and ever-changing market, the demand for advanced digital printing solutions has never been higher. Printing Machine’s latest innovation comes at a crucial time, offering businesses a powerful tool to enhance their printing capabilities and stay ahead of the competition.In a world where first impressions matter more than ever, the ability to deliver high-quality, eye-catching printed materials is essential for businesses looking to make a lasting impact on their customers. With Printing Machine’s latest innovation, businesses can take their printing capabilities to the next level, producing stunning prints with efficiency and ease.The new printing machine is set to be released to the market in the coming months, and industry experts are already predicting that it will be a game-changer for businesses looking to elevate their printing capabilities. With its advanced features, high-speed printing capabilities, and exceptional print quality, the new machine is poised to make a significant impact in the world of digital printing.For businesses looking to stay ahead of the curve and deliver outstanding printed materials, Printing Machine’s latest innovation offers an exciting opportunity to enhance their capabilities and stand out in a crowded market. As the company continues to push the boundaries of what is possible in digital printing, businesses can look forward to a future filled with new opportunities for growth and success.

Efficient and Cost-Effective Bag Cutting Machines for Various Industries

PP Bag Cutting Machine Streamlines Manufacturing Process for Packaging IndustryThe packaging industry is one of the largest and most diverse sectors of the manufacturing industry, with a wide range of products and materials used to create custom packaging solutions for businesses across the globe. In order to keep up with the growing demand for high-quality packaging materials, manufacturers need to utilize the latest technologies and equipment to streamline their processes and improve efficiencies.One such technology is the PP bag cutting machine which is now being widely adopted by packaging companies around the world. This advanced machine has revolutionized the way packaging materials are produced, making it faster, easier, and more cost-effective for manufacturers to create custom packaging solutions for their clients.Combining advanced features with a user-friendly design, these machines are able to cut and shape polypropylene bags with extreme precision, producing high-quality products that meet the demanding standards of the packaging industry. These machines not only reduce the time and effort required to create packaging materials, but they also help to reduce the amount of waste generated during the manufacturing process.One of the leading manufacturers of PP bag cutting machines is a company based in China. Boasting over 20 years of experience in the packaging industry, they are known for their innovative solutions and quality products. Their PP bag cutting machines are designed to handle a wide range of materials and can be customized to meet the specific needs of each client.The company's PP bag cutting machine features a state-of-the-art cutting system that allows for precise and accurate cuts, resulting in a high-quality finish. The machine is also equipped with a variable speed motor, which allows for greater control over the cutting process, as well as a touch screen control panel which makes it easy to adjust settings and operate the machine.One of the key benefits of the company's PP bag cutting machine is its versatility. It can be used to create a wide range of products, from simple bags and pouches to more complex shapes and designs. It can also be used to cut a variety of materials, including woven and non-woven fabrics, as well as films and laminates.The machine is also designed to be easy to use, with a straightforward design that minimizes the time and effort required for set up and operation. It also comes with a range of safety features, including an emergency stop button and overload protection, to ensure the safety of operators and equipment.The company's commitment to quality and innovation has earned them a reputation as a leader in the packaging industry. Their PP bag cutting machines are used by businesses of all sizes, from small startups to multinational corporations, in industries ranging from food and beverage to industrial and pharmaceutical.In addition to their PP bag cutting machines, the company also offers a range of other cutting and welding solutions for the packaging industry. These include ultrasonic cutting machines, high frequency welding machines, and hot air welding machines, all designed to streamline the manufacturing process and improve efficiencies.As the demand for high-quality packaging materials continues to grow, companies in the packaging industry need to invest in the latest technologies and equipment to stay ahead of the competition. The PP bag cutting machine is one such technology, offering a range of benefits that can help businesses improve their processes, reduce waste, and increase profitability.If you're a manufacturer in the packaging industry looking for innovative solutions to improve your efficiency and productivity, be sure to check out the company's range of cutting and welding machines, including their state-of-the-art PP bag cutting machine. With their commitment to quality and customer service, they can help you stay ahead of the curve and achieve your goals in a competitive market.

Efficient and Reliable Woven Bag Cutting Machine: An Overview for Better Productivity

Title: Innovative Pp Woven Bag Cutting Machine Revolutionizes Manufacturing ProcessIntroduction:The manufacturing industry is constantly evolving, with companies striving to improve efficiency, reduce costs, and enhance product quality. In this pursuit, cutting-edge technologies play a crucial role, providing innovative solutions to meet the ever-changing demands of the market. One such technological marvel is the state-of-the-art Pp Woven Bag Cutting Machine (brand name removed), a cutting machine that is poised to transform the production process for woven bags.Technological Advancements:The Pp Woven Bag Cutting Machine represents a significant leap forward in the manufacturing sector. It is equipped with advanced features and cutting-edge technology that enable it to seamlessly cut and shape woven bags with precision and efficiency. Using a combination of intelligent software, mechanical innovations, and customizable settings, this machine ensures maximum productivity while minimizing waste and errors.Versatility and Customization:One of the standout features of the Pp Woven Bag Cutting Machine is its versatility. It can cater to a wide range of bag sizes and designs, making it the ideal choice for businesses in various industries, such as agriculture, construction, and logistics. The machine's ability to handle varying bag dimensions and designs allows manufacturers to easily adapt their production processes to meet changing customer demands, ensuring customer satisfaction and maintaining a competitive edge in the market.The machine's customizable settings further enhance its adaptability. Manufacturers can easily adjust cutting speed, length, and depth to match specific bag requirements, reducing material wastage and increasing overall production efficiency. This flexibility ensures that every bag meets the desired standards and specifications, minimizing product defects and enhancing quality control.Increased Efficiency and Cost-Effectiveness:The Pp Woven Bag Cutting Machine significantly accelerates the production process, resulting in enhanced efficiency for manufacturers. With its ability to cut a large number of bags in a minimal amount of time, manufacturers can meet high-volume demands without compromising on quality. Moreover, the machine's intelligent system reduces downtime by automating various processes, allowing manufacturers to save both time and labor costs.Additionally, the machine's precise cutting mechanism ensures minimal material wastage. By utilizing advanced sensors, it can identify and precisely cut the woven fabric, reducing errors and minimizing unnecessary consumption of material. This reduces raw material costs and helps companies achieve sustainable and environmentally friendly manufacturing practices.Improved Operator Experience:In addition to its technological advancements, the Pp Woven Bag Cutting Machine prioritizes the comfort and safety of its operators. The machine is equipped with user-friendly controls, an intuitive interface, and advanced safety features. These features not only simplify the machine operation but also minimize the risk of accidents, ensuring a safer working environment for operators and reducing the occurrence of occupational injuries.Conclusion:The Pp Woven Bag Cutting Machine revolutionizes the manufacturing process for woven bags, setting new standards in efficiency, productivity, and quality. With its versatility, customization options, and advanced features, this cutting machine enables manufacturers to meet the evolving demands of the market effectively. Embracing this cutting-edge technology ensures streamlined production processes, reduced costs, and improved product quality, cementing a strong position for businesses in the competitive manufacturing landscape.

6 Cavity Automatic Blow Molding Machine revolutionizes PET production

A new breakthrough in the world of bottle production has been made by a leading manufacturing company who have launched an advanced PET 6 Cavity Automatic Blow Molding Machine. With this new technology, the company aims to streamline the bottle production process dramatically, and to bring more efficiency and profitability to their clients who are in the beverage, pharmaceutical, and personal care markets.Speaking about the launch of the new machine, the company spokesperson explained that it was a result of constant innovation and deep understanding of the customer's needs. He added that the PET 6 Cavity Automatic Blow Molding Machine is a product of the company's quest for perfection, with features that surpass the latest trends in the industry. The machine, which has been designed by expert engineers, is built with a powerful hydraulic system, advanced PLC control system, and cutting-edge electro-pneumatic controls designed to make the production of PET bottles speedier, easier, and more cost-effective.The PET 6 Cavity Automatic Blow Molding Machine has a remarkable production capacity of up to 10,000 bottles per hour. This high-speed production capability enables customers to meet the overwhelming demand of their products in the market without sacrificing quality. Additionally, the machine is fitted with a preform loading system and a preform elevator, which enhances the operation's speed and safety.Another great feature of the PET 6 Cavity Automatic Blow Molding Machine is its energy efficiency. The company spokesperson stated that the machine has been designed to save energy and reduce carbon footprint, which is in line with their commitment to environmental sustainability. This has been achieved by installing an energy-efficient screw compressor, with less energy consumption and reduced noise pollution.As part of the company's unwavering commitment to providing tailored solutions to customers, the PET 6 Cavity Automatic Blow Molding Machine has been featured with a user-friendly control panel, which enables novice operators to monitor and regulate operation smoothly. Furthermore, the machine is automated such that the production process requires minimal human intervention, thus reducing the risk of human errors.The PET 6 Cavity Automatic Blow Molding Machine also has a unique bottle ejecting system, which ensures that the bottles produced do not get damaged during the process. The bottles are precisely transferred from the production line onto the ejector, where they are subsequently released into a bottle sorting system.It was further revealed that the PET 6 Cavity Automatic Blow Molding Machine has been tested and awarded several safety certifications by reputable organizations. These certifications are a testament to the machine's durability, reliability, and safety, thereby giving customers peace of mind as they invest in a robust and efficient machine.The spokesperson concluded by stating that the PET 6 Cavity Automatic Blow Molding Machine is a game-changer in the manufacturing industry, offering immense benefits to customers worldwide. He added that the company would continue to provide innovative solutions and excellent customer service to meet the ever-evolving needs of their esteemed clients.In conclusion, the PET 6 Cavity Automatic Blow Molding Machine is an impressive technological achievement that promises to improve the bottle production process and to transform the beverage, pharmaceutical, and personal care industries. Its cutting-edge features, energy efficiency, and safety certifications make it an ideal investment for companies that are looking to enhance their sales and revenue.