New Twist and Gusset Machine for Woven Bag Offers Improved Efficiency and Quality

By:Admin

[Brand Name] is a leading manufacturer of packaging machinery, specializing in the design and production of high-quality equipment for the packaging industry. With a strong focus on innovation and customer satisfaction, [Brand Name] has become a trusted name in the industry, known for its commitment to delivering top-notch products and exceptional service.

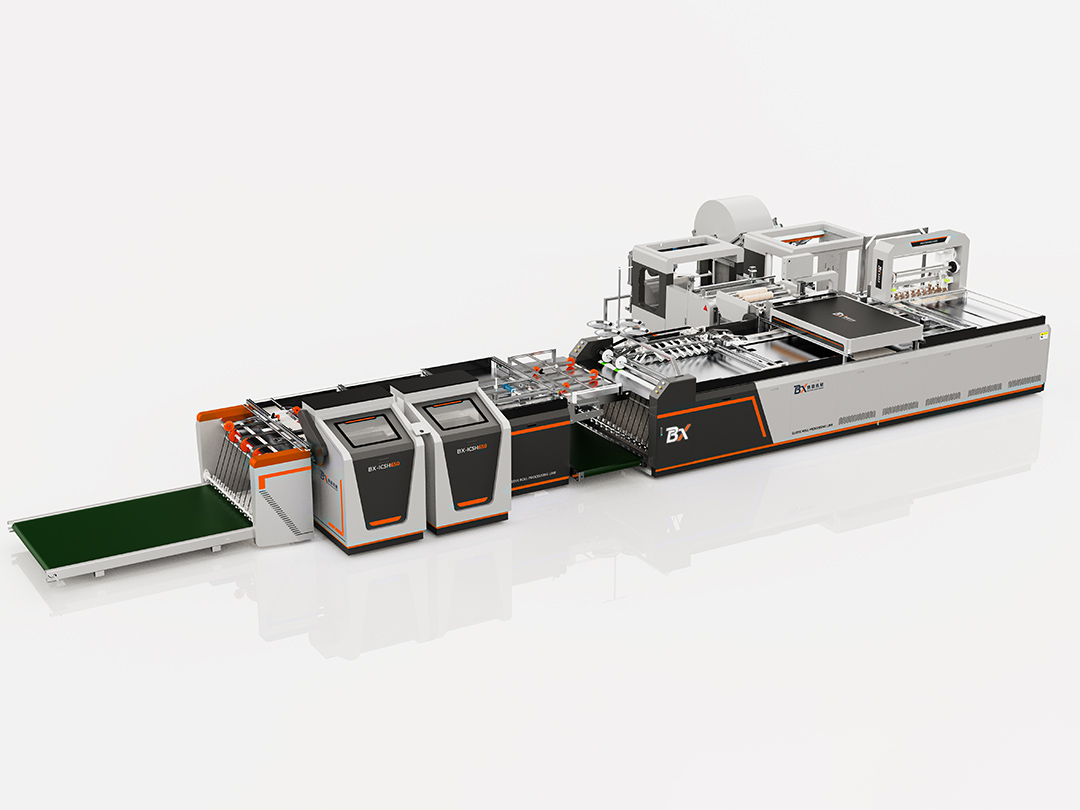

The twist and gusset machine for woven bags is the latest addition to [Brand Name]'s impressive line of packaging machinery. This state-of-the-art machine is designed to meet the growing demand for high-quality woven bags with twist and gusset features, providing bag manufacturers with a reliable and efficient solution for producing top-notch woven bags.

One of the key features of the twist and gusset machine is its advanced technology, which allows for precise and accurate twisting and gusseting of woven bags. This level of precision ensures that every bag produced meets the highest standards of quality, providing customers with a reliable and durable packaging solution.

In addition to its cutting-edge technology, the twist and gusset machine also offers a high level of efficiency, helping bag manufacturers increase their production capacity and reduce production costs. This is achieved through the machine's automated operation, which streamlines the bag manufacturing process and minimizes the need for manual intervention.

Furthermore, the twist and gusset machine is designed with user-friendly features, making it easy for operators to set up, operate, and maintain the equipment. This minimizes downtime and ensures a smooth and hassle-free production process, allowing bag manufacturers to meet tight deadlines and customer demands with ease.

The twist and gusset machine for woven bags is quickly gaining popularity within the packaging industry, with bag manufacturers recognizing the significant benefits it offers. Whether producing bags for the agriculture, construction, or industrial sectors, the machine provides a versatile solution for meeting diverse packaging needs.

[Brand Name] is proud to be at the forefront of this innovation, and the company's commitment to delivering top-quality products and exceptional service has solidified its reputation as a leader in the packaging machinery industry. With a strong focus on customer satisfaction and continuous improvement, [Brand Name] is well-positioned to meet the evolving needs of bag manufacturers around the world.

As the demand for high-quality woven bags continues to grow, the twist and gusset machine for woven bags developed by [Brand Name] is poised to play a key role in the industry. With its advanced technology, efficiency, and user-friendly design, the machine is proving to be a game-changer for bag manufacturers, providing them with the tools they need to stay competitive in a fast-paced and demanding market.

In conclusion, the twist and gusset machine for woven bags developed by [Brand Name] is a testament to the company's dedication to innovation and excellence. This innovative machine is not only reshaping the way woven bags are manufactured but also empowering bag manufacturers to meet the evolving needs of their customers with confidence and efficiency. As the packaging industry continues to evolve, [Brand Name] remains committed to staying at the forefront of innovation, delivering cutting-edge solutions that drive success for its customers.

Company News & Blog

New Innovative Print Machine Boosts Efficiency and Productivity in the Market

Title: Advanced Print Machine Revolutionizes CI Industry with Cutting-Edge TechnologyIntroductionIn a significant breakthrough for the continuous inkjet (CI) printing industry, a leading technology company has unveiled its latest innovation, an advanced CI print machine. This groundbreaking new device, with its state-of-the-art features and cutting-edge technology, promises to revolutionize the printing and packaging sector. By offering improved efficiency, environmental sustainability, and enhanced print quality, this revolutionary CI print machine sets a new standard in the industry.Deep DiveThe introduction of this game-changing CI print machine comes as a result of extensive research and development efforts by the company's team of highly skilled engineers. By successfully integrating advanced technologies and innovative features, this print machine is tailored to meet the diverse needs of the printing industry.With an emphasis on sustainability, the new CI print machine boasts substantial improvements in terms of energy consumption and resource efficiency. By implementing intelligent power management systems, the machine achieves a significant reduction in power consumption, resulting in lower operating costs for businesses while minimizing its environmental impact.Furthermore, the print machine utilizes a cutting-edge ink formulation that maximizes ink usage, reducing ink wastage and promoting sustainability in the printing process. The intelligently designed ink system ensures precise ink control, enabling high-quality prints while minimizing ink consumption.Another groundbreaking feature of this CI print machine is its enhanced print speed. With its advanced print head technology, the machine achieves uninterrupted high-speed printing, leading to improved productivity and reduced production timelines. This allows businesses to meet tight deadlines and high-volume demands, giving them a competitive edge in the market.Moreover, the CI print machine is equipped with intelligent sensors that detect and correct printing errors in real-time, ensuring consistent print quality throughout the production process. This technology reduces the need for reprints, thus minimizing cost and material waste. The resulting print quality surpasses the industry norm, providing businesses with impressive visual appeal and accuracy in their printed materials.The user-friendly interface of the CI print machine further enhances its appeal to businesses. With its intuitive controls and simplified operation, it offers effortless set-up and printing processes. The built-in troubleshooting system provides easy diagnosis and resolution of any technical issues, reducing downtime and maximizing efficiency.In addition to its innovative features, the CI print machine is designed to seamlessly integrate into existing production lines, making it a versatile solution for businesses of all sizes. This compatibility ensures a smooth transition to the advanced print technology without requiring a complete overhaul of the existing infrastructure.The CI print machine is set to create a significant impact in the packaging industry, particularly in applications such as food and beverage packaging, pharmaceutical labeling, and product branding. Its ability to deliver consistently high-quality prints, combined with its environmentally friendly features, makes it an ideal choice for companies aiming to enhance brand value and consumer satisfaction.ConclusionWith its advanced technology and groundbreaking features, the new CI print machine is poised to revolutionize the printing and packaging industry. The integration of sustainability, increased efficiency, and superior print quality sets a new industry standard. Businesses can now benefit from reduced costs, enhanced productivity, and improved environmental sustainability, positioning themselves at the forefront of their respective markets. The launch of this groundbreaking CI print machine undoubtedly proves the company's commitment to technological innovation and its dedication to providing cutting-edge solutions to meet evolving industry needs.

High-Quality Pp Woven Bag Making Machine for Efficient Production

Pp Woven Bag Making Machine Revolutionizes Production ProcessThe global packaging industry has witnessed a significant transformation in recent years, with the introduction of advanced machinery to streamline the production process. One such remarkable innovation is the Pp Woven Bag Making Machine, which has revolutionized the manufacturing of woven bags and packaging materials. The machine, developed by an industry-leading company specializing in packaging solutions, has set a new standard for efficiency and quality in bag production.The Pp Woven Bag Making Machine is equipped with state-of-the-art technology and advanced features that enhance the production process. It is capable of producing a wide range of woven bags, including shopping bags, packaging bags, and industrial bags, with precision and consistency. The machine's high-speed operation and automated functions allow for maximum output and minimal downtime, resulting in increased productivity and cost savings for manufacturers.One of the key advantages of the Pp Woven Bag Making Machine is its versatility and flexibility in producing customized bag designs. The machine can accommodate various specifications, including bag size, thickness, printing, and lamination options, to meet the diverse needs of customers. This capability is particularly valuable for businesses looking to differentiate their products and brand through unique packaging solutions.In addition to its advanced manufacturing capabilities, the Pp Woven Bag Making Machine is also designed for sustainability and environmental responsibility. The machine utilizes eco-friendly materials and processes to reduce waste and minimize its carbon footprint. This aligns with the growing demand for sustainable packaging solutions in the market, as businesses and consumers alike prioritize environmentally friendly alternatives.The company behind the Pp Woven Bag Making Machine is a renowned leader in the packaging industry, with a track record of delivering innovative solutions to global markets. With a strong focus on research and development, the company has consistently pushed the boundaries of technology to create cutting-edge machinery that meets the evolving needs of the industry.Furthermore, the company's commitment to customer satisfaction and support sets it apart as a trusted partner for businesses seeking reliable packaging solutions. Its team of experts provides comprehensive training, technical assistance, and after-sales services to ensure seamless integration and operation of the Pp Woven Bag Making Machine. This dedication to customer success has earned the company a reputation for excellence and reliability in the market.The introduction of the Pp Woven Bag Making Machine represents a significant milestone in the packaging industry, setting new standards for efficiency, quality, and sustainability in bag production. Its advanced capabilities and commitment to customer satisfaction position it as a game-changing solution for manufacturers seeking to elevate their packaging processes.As the demand for woven bags and sustainable packaging solutions continues to grow, the Pp Woven Bag Making Machine is poised to make a lasting impact on the industry. With its innovative technology and unwavering commitment to excellence, the machine is set to lead the way in redefining the future of bag production and elevating the overall standard of packaging solutions worldwide.

High-Quality Woven Bag Making Machine for Efficient Production

Woven Bag Making Machine Brings Innovation to Packaging IndustryIn the fast-paced and ever-evolving world of packaging and manufacturing, innovation is the key to staying ahead of the competition. One such innovation comes in the form of the Woven Bag Making Machine by a leading machinery manufacturer. This state-of-the-art machine has revolutionized the process of creating woven bags, bringing efficiency and precision to the packaging industry.The Woven Bag Making Machine is designed to produce high-quality woven bags with speed and precision. It is equipped with advanced technology and features that allow for seamless production and consistent results. The machine is capable of creating a wide range of woven bags, including those used for packaging agricultural products, food items, and industrial materials.One of the key features of the machine is its versatility. It can accommodate various types of woven fabrics, allowing for customization and flexibility in bag design. Additionally, the machine is equipped with precision cutting and stitching mechanisms, ensuring that each bag is of the highest quality.Furthermore, the Woven Bag Making Machine is designed with efficiency in mind. Its automated processes and streamlined workflow reduce the need for manual labor, resulting in faster production times and reduced operating costs. This not only benefits manufacturers but also contributes to a more sustainable and environmentally friendly production process.In addition to its technical capabilities, the Woven Bag Making Machine is backed by a reputable machinery manufacturer. With years of experience and expertise in the industry, the company has a strong track record of delivering high-quality machinery to businesses around the world. Their commitment to innovation and customer satisfaction has made them a trusted partner for businesses in the packaging and manufacturing sector.The company's dedication to quality and service is also reflected in their after-sales support and maintenance services. They offer comprehensive training programs for operators and maintenance personnel, ensuring that the Woven Bag Making Machine operates at its full potential. Additionally, their responsive customer service team is always available to provide assistance and support, further enhancing the value of their products.The introduction of the Woven Bag Making Machine has been met with enthusiasm and excitement in the packaging industry. Its advanced technology and efficiency have positioned it as a game-changer for businesses looking to enhance their packaging capabilities. With its proven track record and the backing of a reputable manufacturer, the machine is set to make a significant impact on the market.As the demand for high-quality woven bags continues to grow, the Woven Bag Making Machine offers businesses a competitive edge in meeting customer needs. Its ability to produce customized, durable, and aesthetically appealing bags sets a new standard for packaging solutions. Furthermore, its efficient production process and low operating costs make it an attractive investment for manufacturers looking to optimize their operations.In conclusion, the Woven Bag Making Machine represents a significant advancement in the packaging industry. Its technological capabilities, combined with the expertise and support of a reputable manufacturer, make it a valuable asset for businesses seeking to elevate their packaging capabilities. With its potential to enhance efficiency, quality, and sustainability, the machine is poised to lead the way in the future of woven bag production.

The Latest Woven Sack Lamination Machine Technology in the News

Woven sack lamination machine is a crucial piece of equipment in the packaging industry. It is used to create laminated woven bags that are strong, durable, and resistant to moisture and other environmental factors. These bags are highly versatile and widely used in various industries including agriculture, construction, and transportation.One of the leading manufacturers of woven sack lamination machines is {}. With years of experience and expertise in the industry, they have gained a reputation for producing high-quality, reliable, and efficient machines that meet the needs of their customers.The [Company Name] woven sack lamination machine is designed to meet the ever-growing demand for durable and cost-effective packaging solutions. It is equipped with advanced technology and features that ensure seamless operation and consistent production of high-quality laminated woven sacks.The machine is capable of laminating a wide range of materials including PP (Polypropylene) woven fabric, BOPP (Biaxially Oriented Polypropylene) film, and other types of laminates. This versatility allows manufacturers to produce custom laminated woven sacks according to their specific requirements.The lamination process performed by the machine enhances the strength and durability of the woven sacks, making them ideal for packaging heavy and bulky products. The laminated bags also offer excellent barrier properties, protecting the contents from moisture, UV radiation, and other external factors.With a focus on efficiency and productivity, the {} woven sack lamination machine is designed for high-speed operation while maintaining precision and accuracy. This ensures that manufacturers can meet their production targets without compromising on the quality of the laminated bags.In addition to its advanced features, the machine is also user-friendly, with intuitive controls and interfaces that make operation and maintenance easy and convenient. This helps in minimizing downtime and optimizing the overall production process.The {} woven sack lamination machine is backed by a team of skilled engineers and technicians who provide excellent technical support and after-sales service. This ensures that customers can rely on the machine for continuous and reliable operation, contributing to their overall operational efficiency and success.The company's commitment to quality, innovation, and customer satisfaction has earned them a strong market presence and a loyal customer base. They strive to stay ahead of the curve by continuously improving their machines and adapting to the evolving needs of the packaging industry.As the demand for reliable and sustainable packaging solutions continues to rise, the {} woven sack lamination machine is poised to play a key role in meeting these demands. With its advanced technology, high efficiency, and superior performance, it is set to remain a preferred choice for manufacturers looking to produce high-quality laminated woven sacks.In conclusion, the {} woven sack lamination machine is a testament to the company's dedication to excellence and innovation in the packaging industry. With its advanced capabilities and commitment to customer satisfaction, it is set to make a significant impact in the market and contribute to the success of manufacturers across various industries.

Durable and Eco-Friendly Printed Non Woven Bags for Everyday Use

[Company Name] Introduces Eco-Friendly Printed Non Woven Bags to Promote Sustainable Living[Company Name], a leading provider of eco-friendly products, has recently introduced a new line of printed non woven bags as part of their commitment to promoting sustainability and eco-conscious living.Non woven bags are becoming increasingly popular as an alternative to traditional plastic bags due to their durability, reusability, and environmentally-friendly nature. Unlike plastic bags, non woven bags are made from spunbond polypropylene, a type of thermoplastic polymer that is recyclable and biodegradable. This makes them a more sustainable choice for consumers who are looking to reduce their environmental impact.[Company Name] has taken their commitment to sustainability a step further by offering printed non woven bags, which are not only practical and eco-friendly but also customizable. The company uses a high-quality printing process to create vibrant and eye-catching designs on the bags, making them ideal for promoting businesses, events, and causes while also encouraging the use of reusable bags.In addition to their environmental benefits, the printed non woven bags offered by [Company Name] are also designed to be extremely durable and long-lasting. This means that they can be used repeatedly, reducing the need for single-use plastic bags and ultimately helping to minimize waste.The introduction of these printed non woven bags is in line with [Company Name]'s mission to provide sustainable alternatives to everyday products. The company is dedicated to offering high-quality, eco-friendly solutions that enable consumers to make more environmentally-conscious choices without sacrificing style or functionality."We are thrilled to introduce our new line of printed non woven bags as part of our ongoing commitment to promoting sustainability," said [Company Name] spokesperson. "We believe that it's important for businesses to offer eco-friendly alternatives to traditional products, and our printed non woven bags are a perfect example of this. Not only are they practical and durable, but they also allow our customers to showcase their brand or message in a visually appealing way."The introduction of these printed non woven bags aligns with the growing trend of businesses and consumers alike moving towards more sustainable practices. With increasing awareness of the environmental impact of single-use plastics, there is a growing demand for reusable and eco-friendly alternatives. [Company Name] aims to meet this demand by providing a stylish and practical solution that promotes sustainable living.The printed non woven bags offered by [Company Name] are available in a variety of sizes, styles, and designs, making them suitable for a wide range of applications. Whether used for grocery shopping, carrying everyday essentials, or promoting a brand or event, these bags offer a versatile and eco-friendly solution.As the global movement towards sustainability continues to gain momentum, the introduction of printed non woven bags by [Company Name] is a timely and welcome addition to the market. By offering a practical and customizable alternative to single-use plastic bags, the company is empowering consumers and businesses to make a positive impact on the environment while also meeting their everyday needs.With their dedication to promoting sustainability and eco-conscious living, [Company Name] is setting a commendable example for businesses seeking to make a positive difference in the world. The introduction of their printed non woven bags is a significant step towards reducing plastic waste and encouraging responsible consumption, and is sure to be well-received by consumers and businesses alike.

Top Quality Fabric Bag Machines for Efficient Production

The demand for eco-friendly and sustainable products has been steadily increasing in recent years, and {Company Name} is proud to be at the forefront of this movement with their innovative fabric bag machine. The company, known for their commitment to environmental sustainability and social responsibility, has developed a cutting-edge machine that is revolutionizing the production of fabric bags.The fabric bag machine, which is the latest addition to {Company Name}'s line of sustainable packaging solutions, is designed to meet the growing demand for reusable bags as consumers and businesses seek alternatives to single-use plastic bags. This state-of-the-art machine is capable of producing high-quality fabric bags at a rapid pace, making it an efficient and cost-effective solution for businesses looking to reduce their environmental impact.In addition to its impressive production capabilities, the fabric bag machine is also designed with sustainability in mind. It is equipped with advanced technology that minimizes waste and maximizes energy efficiency, ensuring that the production process is as eco-friendly as possible. This aligns with {Company Name}'s overarching mission to prioritize sustainability and reduce their carbon footprint across all aspects of their operations.The introduction of the fabric bag machine is a testament to {Company Name}'s ongoing commitment to environmental stewardship. As a company that has long been dedicated to providing sustainable packaging solutions, they recognize the importance of offering alternatives to traditional plastic bags that are harmful to the environment. The fabric bag machine is a reflection of their dedication to finding innovative and pragmatic solutions to address the pressing issue of plastic pollution.Moreover, {Company Name} is not only providing a solution to the growing demand for eco-friendly bags but also setting an example for other companies in the packaging industry. By investing in sustainable technology and prioritizing environmental responsibility, they are demonstrating that it is possible to balance business success with a commitment to the planet.The fabric bag machine is just one of {Company Name}'s many initiatives aimed at reducing the environmental impact of packaging. They have also implemented a range of other sustainable practices within their operations, such as using recycled materials in their products and optimizing their supply chain to minimize transportation emissions. By taking a comprehensive approach to sustainability, they are working to create a more environmentally-friendly future for the packaging industry as a whole.As the fabric bag machine enters the market, it is expected to have a transformative impact on the way businesses approach their packaging needs. With the ability to produce high-quality fabric bags in a sustainable and efficient manner, it presents an attractive alternative to traditional plastic bags. This is particularly significant as more and more consumers and businesses are seeking out eco-friendly options in response to the global movement to reduce plastic waste.The introduction of the fabric bag machine also underscores {Company Name}'s commitment to corporate social responsibility. By offering a sustainable alternative to plastic bags, they are contributing to the global effort to reduce plastic pollution and protect the environment. This aligns with their broader mission to operate in a manner that is socially and environmentally responsible, and to make a positive impact on the world.In conclusion, the introduction of {Company Name}'s fabric bag machine represents a significant step forward in the pursuit of sustainable packaging solutions. By offering a cutting-edge machine that is capable of producing high-quality fabric bags in an efficient and environmentally friendly manner, they are setting a new standard for the packaging industry. With their ongoing commitment to sustainability and environmental responsibility, {Company Name} is leading the way towards a more sustainable future for packaging.

High-Quality Woven Sack Making Machine for Your Business Needs

Woven Sack Making Machine Revolutionizing the Packaging IndustryIn today's fast-paced world, the packaging industry plays a vital role in ensuring the safe transportation and storage of goods. With the increasing demand for packaging materials, the need for innovative and efficient manufacturing solutions has become more apparent than ever. This is where the Woven Sack Making Machine comes into the picture, offering state-of-the-art technology to revolutionize the packaging industry.The Woven Sack Making Machine, offered by [Company Name], is designed to produce high-quality woven sacks that are widely used for packaging a variety of products such as grains, chemicals, fertilizers, cement, and more. This advanced machine is equipped with cutting-edge features that enable seamless production of woven sacks with enhanced strength, durability, and flexibility.[Company Name] has established itself as a leading provider of machinery and equipment for the packaging industry. With a strong focus on innovation and customer satisfaction, the company has earned a reputation for delivering reliable and cutting-edge solutions to its clients worldwide. The Woven Sack Making Machine is a testament to the company's commitment to offering advanced technology that meets the evolving needs of the packaging industry.One of the key features of the Woven Sack Making Machine is its high production capacity, which allows for the efficient manufacturing of woven sacks in large volumes. This not only increases productivity but also ensures that the demand for packaging materials can be met effectively. Moreover, the machine is designed for easy operation and maintenance, making it a cost-effective solution for packaging manufacturers.The Woven Sack Making Machine is also equipped with advanced automation features that allow for precise control over the production process. This results in consistent quality and uniformity in the woven sacks produced, which is crucial for meeting the stringent requirements of the packaging industry. Additionally, the machine is designed to minimize waste and optimize raw material usage, contributing to sustainable and eco-friendly manufacturing practices.The versatility of the Woven Sack Making Machine makes it suitable for a wide range of applications in the packaging industry. Whether it is for the production of standard woven sacks or customized packaging solutions, the machine can be tailored to meet specific requirements. This flexibility allows packaging manufacturers to adapt to changing market demands and offer innovative solutions to their clients.As the demand for sustainable packaging solutions continues to rise, the Woven Sack Making Machine is well-positioned to meet this need. The machine is capable of producing woven sacks from a variety of eco-friendly materials, further contributing to the global efforts towards environmental conservation. This aligns with [Company Name]'s commitment to sustainable manufacturing practices and corporate responsibility.With a strong emphasis on research and development, [Company Name] continues to enhance the capabilities of the Woven Sack Making Machine to address the evolving needs of the packaging industry. The company's dedication to innovation and customer satisfaction has earned the trust of packaging manufacturers worldwide, making the Woven Sack Making Machine a preferred choice for enhancing productivity and quality in the production of woven sacks.In conclusion, the Woven Sack Making Machine offered by [Company Name] represents a significant advancement in the packaging industry. With its advanced technology, high production capacity, and versatility, the machine is well-equipped to meet the growing demand for packaging materials while promoting sustainable manufacturing practices. As packaging manufacturers continue to seek efficient and reliable solutions, the Woven Sack Making Machine stands as a game-changer in the industry, driving innovation and excellence in packaging production.

Efficient and Reliable Liner Inserting Machine for Streamlined Production

Liner Inserting Machine Revolutionizes Packaging IndustryThe packaging industry has undergone significant advancements in recent years, with the introduction of innovative technologies that have streamlined manufacturing processes and improved overall efficiency. One such technology that has gained widespread attention is the Liner Inserting Machine, a state-of-the-art equipment that has revolutionized the way packaging materials are handled and processed.The Liner Inserting Machine, developed by a leading packaging machinery manufacturer, is a versatile and highly efficient piece of equipment that is designed to automatically insert liners into various packaging containers. The machine is capable of handling a wide range of liner materials, including paper, plastic, and aluminum, making it an ideal solution for companies that have diverse packaging needs.With its advanced automation features and intuitive control system, the Liner Inserting Machine is able to streamline the liner insertion process, reducing the need for manual intervention and significantly improving production output. This not only translates to cost savings for companies but also ensures consistency and accuracy in liner placement, thereby enhancing the overall quality of the packaged products.The company behind the Liner Inserting Machine has a long-standing reputation for delivering cutting-edge packaging solutions to the industry. With a strong focus on research and development, the company has consistently introduced technological innovations that have set new standards for packaging machinery. In addition to the Liner Inserting Machine, the company offers a comprehensive range of packaging equipment, including filling machines, capping machines, and labeling machines, catering to the diverse needs of its global clientele.Furthermore, the company takes pride in its commitment to sustainability and environmental responsibility. The Liner Inserting Machine, in particular, is designed with energy-efficient components and processes, minimizing its environmental impact while maximizing its operational efficiency. This aligns with the company's broader mission to deliver sustainable packaging solutions that support the growing demand for eco-friendly practices in the industry.The Liner Inserting Machine has garnered praise from packaging professionals and industry experts for its exceptional performance and reliability. Its ability to handle various liner materials with precision and speed has made it a valuable asset for companies seeking to optimize their packaging operations. Additionally, the machine's user-friendly interface and low maintenance requirements have made it a preferred choice for companies looking to enhance their production capabilities.In response to the positive reception of the Liner Inserting Machine, the company has continued to invest in research and development, driving further advancements in packaging technology. By staying at the forefront of innovation, the company is well-positioned to address the evolving needs of the packaging industry and deliver solutions that empower companies to thrive in a competitive market.Looking ahead, the company remains dedicated to its core values of innovation, quality, and customer satisfaction. As the demand for efficient and sustainable packaging solutions continues to grow, the company is poised to lead the way with its pioneering technologies and commitment to excellence. The Liner Inserting Machine, in particular, stands as a testament to the company's relentless pursuit of advancement and its unwavering dedication to shaping the future of packaging.

High-quality Woven Making Machine for Efficient Production

Woven Making Machine Revolutionizing the Textile IndustryThe textile industry has always been at the forefront of innovation and technological advancements. One such advancement that is making waves in the industry is the introduction of the Woven Making Machine, which is set to revolutionize the way textiles are produced.This cutting-edge machine, developed by an industry-leading company, is equipped with state-of-the-art technology and advanced features that are designed to enhance efficiency, productivity, and quality in the manufacturing of woven fabrics. It is a game-changer for textile manufacturers, enabling them to meet the growing demand for high-quality textiles while remaining competitive in the global market.The Woven Making Machine boasts a range of impressive features that set it apart from traditional weaving machines. Its advanced automation and digital control system allow for precise and consistent fabric production, eliminating the variability and errors often associated with manual weaving processes. This not only improves the quality of the end product but also reduces wastage and enhances overall production efficiency.Furthermore, the machine is capable of producing a wide variety of woven fabrics, including plain weaves, twills, and satins, among others. This versatility makes it an ideal choice for textile manufacturers looking to cater to diverse market demand and explore new design possibilities.In addition to its advanced technical capabilities, the Woven Making Machine is also designed with sustainability in mind. It features energy-efficient components and innovative design elements that minimize environmental impact and contribute to a more sustainable manufacturing process. This aligns with the growing industry trend towards sustainable and ethical production practices, further positioning the machine as a valuable asset for forward-thinking textile manufacturers.The company behind the Woven Making Machine is a global leader in textile machinery and equipment manufacturing. With a rich history of innovation and a strong commitment to research and development, the company has consistently delivered cutting-edge solutions that have reshaped the textile industry. Their expertise, combined with a deep understanding of the evolving needs of textile manufacturers, has enabled them to develop the Woven Making Machine as a response to the industry's demand for smarter, more efficient production solutions.In addition to the Woven Making Machine, the company offers a comprehensive range of textile machinery and equipment, catering to the entire production process from spinning and weaving to finishing and quality control. With a focus on innovation, reliability, and customer satisfaction, the company has established itself as a trusted partner for textile manufacturers worldwide, providing them with the tools they need to stay competitive and meet the demands of a rapidly changing market.The introduction of the Woven Making Machine marks a significant milestone in the evolution of textile production. Its advanced technology, versatility, and commitment to sustainability make it a valuable asset for textile manufacturers looking to enhance their production capabilities and stay ahead of the competition. As the industry continues to evolve, innovative solutions like the Woven Making Machine will play a crucial role in driving progress and shaping the future of textile manufacturing. With the support of companies at the forefront of innovation, the industry is poised to embrace the opportunities and challenges that lie ahead, setting the stage for a new era of excellence in textile production.

Guide to Roll-to-Roll Lamination Machines: What You Need to Know

Title: Roll-To-Roll Lamination Machine Revolutionizes Packaging IndustryIntroduction:In today's fast-paced consumer-driven world, packaging plays a crucial role in attracting customers and preserving product integrity. As a result, manufacturers are constantly seeking innovative solutions to enhance their packaging capabilities. A pioneer in the field, a leading technology company has launched an advanced Roll-To-Roll Lamination Machine that is set to revolutionize the packaging industry.In this news article, we will delve into the key features and benefits of this groundbreaking machine, explore its potential implications for the packaging industry, and highlight how this investment aligns with the company's commitment to delivering cutting-edge solutions to its clients.Unveiling the Next-Generation Roll-To-Roll Lamination Machine:The recently introduced Roll-To-Roll Lamination Machine, developed after extensive research and development, is highly efficient and seamlessly automates the packaging process. It offers revolutionary features that will significantly enhance productivity, reduce costs, and improve the overall quality of packaging.Key Features and Benefits:1. High-Speed Performance: The Roll-To-Roll Lamination Machine boasts an impressive production speed, enabling manufacturers to meet increasing demands while maintaining a competitive edge in the market. It can achieve seamless lamination of materials, ensuring excellent quality with minimal defects.2. Versatile and Wide Range of Capability: This machine supports the lamination of various materials, including paper, film, and foil, allowing manufacturers to adapt to different product requirements. Its versatility is a game-changer for packaging companies looking to diversify their offerings without investing in multiple machines.3. Advanced Control System: Equipped with state-of-the-art control systems, this machine provides manufacturers with precise control over critical parameters such as temperature, pressure, and speed. The user-friendly interface and intuitive control panel simplify operations, reducing the learning curve for operators.4. Cost-Effective Solution: The Roll-To-Roll Lamination Machine optimizes material usage and reduces waste significantly, resulting in substantial cost savings for packaging manufacturers. Additionally, its efficient design reduces energy consumption, making it an environmentally friendly choice.Implications for the Packaging Industry:The introduction of this advanced Roll-To-Roll Lamination Machine disrupts the traditional packaging landscape, empowering manufacturers with enhanced capabilities and flexibility. This innovation is expected to revolutionize how packaging companies approach their production processes, offering a competitive advantage and bringing new opportunities for growth.The reduction in production time, elimination of manual errors, and increased versatility of the machine enable manufacturers to scale their operations and maintain higher levels of productivity. This, in turn, has a positive impact on meeting market demands promptly and ensures timely delivery to retailers.Moreover, the precise control system and automation features of the machine enhance the overall quality of the packaging, leading to customer satisfaction and increased brand loyalty. The ability to work with different materials enables manufacturers to explore new markets and target a broader range of industries, expanding their customer base.Company's Commitment to Innovation:As a renowned technology company, {} has always been at the forefront of delivering cutting-edge solutions to its clients. The development and introduction of the Roll-To-Roll Lamination Machine are in line with the company's commitment to innovation and continuous improvement.By investing in research and development, {} aims to empower packaging manufacturers with the latest technology, enabling them to elevate their operations and gain a competitive advantage. This dedication to excellence further solidifies {}'s position as a trusted industry leader and a reliable partner for companies seeking to stay ahead in the ever-evolving packaging industry.Conclusion:The unveiling of the advanced Roll-To-Roll Lamination Machine signifies a significant milestone in the evolution of the packaging industry. With its game-changing features like high-speed performance, exceptional versatility, and precise control, this innovation enables manufacturers to optimize their operations, reduce costs, and produce high-quality packaging consistently.The implications of this innovation extend beyond immediate benefits, opening new avenues for growth, market expansion, and increased customer satisfaction. As {} continues to pioneer technological advancements, it is poised to shape the future of the packaging industry, empowering manufacturers and revolutionizing how products are packaged and presented to consumers.