Leading Manufacturer of Machinery Launches New Product Line

By:Admin

Founded in 2003, Yongming Machine has quickly established itself as a trusted name in the industrial machinery sector. The company's commitment to excellence and customer satisfaction has propelled it to the forefront of the market, earning it a reputation for reliability and performance. With a diverse range of products and a strong emphasis on research and development, Yongming Machine has continuously pushed the boundaries of what is possible in the industry.

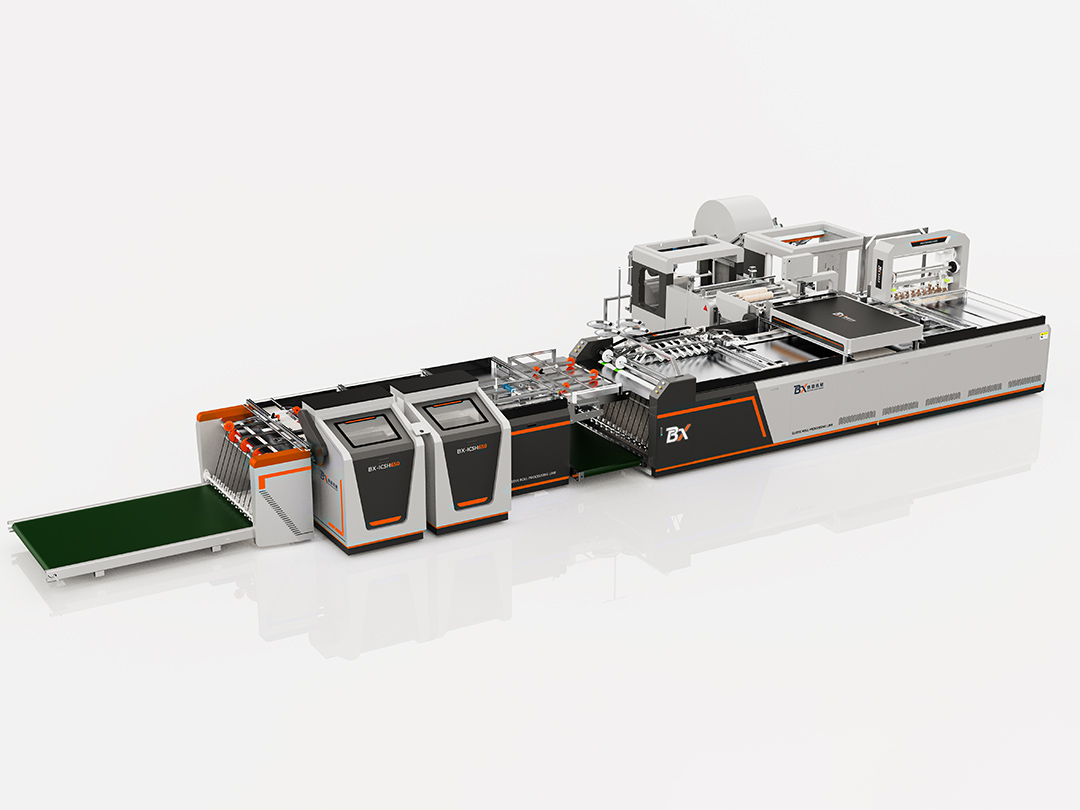

The latest addition to the company's product lineup is a testament to its dedication to staying ahead of the curve. By leveraging the latest technological advancements, Yongming Machine has developed a series of cutting-edge machines that are designed to streamline production processes and enhance overall efficiency. These state-of-the-art solutions are poised to redefine the manufacturing landscape, setting new standards for performance and reliability.

One of the key highlights of the new product line is its focus on automation and smart technology. With the integration of advanced control systems and intelligent monitoring capabilities, these machines are able to optimize production processes and minimize human intervention. This not only results in higher precision and quality control but also enables manufacturers to significantly reduce downtime and operational costs.

In addition to their advanced technological features, the new machines are also designed with versatility and adaptability in mind. Whether it's for metalworking, woodworking, or any other industrial application, Yongming Machine's products are engineered to deliver exceptional performance across a wide range of tasks. This flexibility ensures that customers can meet their specific production needs without compromise, making them an ideal choice for businesses of all sizes.

Furthermore, the new product line from Yongming Machine places a strong emphasis on sustainability and environmental responsibility. By incorporating energy-efficient components and optimizing resource consumption, these machines are not only more eco-friendly but also help businesses reduce their carbon footprint. This aligns with the company's commitment to promoting greener and more sustainable manufacturing practices, ensuring that its products are not only beneficial to the bottom line but also to the planet.

Yongming Machine's dedication to excellence does not end with its products. The company also places a strong emphasis on providing exceptional customer support and service. With a team of highly knowledgeable and experienced professionals, Yongming Machine is dedicated to helping its customers make the most of their investment. Whether it's through technical assistance, training programs, or regular maintenance, the company is committed to being a reliable partner every step of the way.

As the manufacturing industry continues to evolve, the need for advanced machinery that can keep up with growing demands has never been greater. With the launch of its newest product line, Yongming Machine is reaffirming its position as a market leader and setting the stage for a new era of innovation and efficiency. By combining cutting-edge technology with a customer-centric approach, the company is poised to make a lasting impact on the industry, empowering manufacturers to thrive in an increasingly competitive marketplace.

With a steadfast commitment to excellence, continuous improvement, and sustainability, Yongming Machine is well-positioned to shape the future of manufacturing, setting new benchmarks for performance and reliability. As the company continues to push the boundaries of what is possible, it is poised to remain a driving force in the industrial machinery sector for years to come.

Company News & Blog

Machine manufacturer in China launches new product for construction industry

Yongming Machinery Co. (name changed) is a well-known manufacturer of injection molding machines in China. Recently, the company announced the launch of their latest injection machines, aimed at providing high-quality products to the customers while creating a sustainable future.The company's new product line is designed to reduce energy consumption, increase efficiency and minimize waste. They believe that manufacturing companies have a shared responsibility in building more sustainable production processes. With that in mind, Yongming Machinery has invested heavily in developing energy-efficient products. For example, their latest injection molding machine consumes 30% less energy compared to traditional models. The injection machines' intelligent control systems automatically adjust to the production needs, only using the precise amount of energy required. This minimizes power waste and decreases carbon emissions.Moreover, as a company with a strong eco-conscience, Yongming Machinery has incorporated eco-friendly materials and production processes in manufacturing their new injection machines. Their advanced injection machines are built using biodegradable and recyclable components, such as bio-based resins and eco-friendly lubricants. Additionally, their production line employs energy-saving methods, such as recycled water and material management.According to Mr. Zhang, the CEO of Yongming Machinery, the company's focus is on delivering top-quality products with minimum environmental impact. "We're committed to our customers by delivering reliable products that meet their needs while minimizing our carbon footprint. Our latest injection molding machines are the perfect example of that. Our machines' intelligent control systems and eco-friendly components have helped our clients reduce their carbon footprint and waste production significantly. We're proud to have helped them improve their sustainability performance."Yongming Machinery has been a market leader in injection molding machines for more than 10 years. Their experience in the industry has helped them develop products that exceed customers' expectations. Their new injection machines are user-friendly, efficient, and reliable. Their low energy requirement and eco-friendly features make them an ideal option for companies looking to improve their sustainability performance.The company caters to a wide range of industries, including automotive, electronics, packaging, medical, and consumer goods. They offer a variety of robust injection molding machines, ranging from hydraulic to electric motors, and ensure their customers receive excellent after-sale technical support and services. Moreover, the company's technical team provides comprehensive training to their clients on how to operate and maintain their machines, minimizing downtime and maximizing productivity.Yongming Machinery's competitive edge is their commitment to innovation. They invest heavily in their R&D department, ensuring their products are at the forefront of technology. The company's focus on innovation has led to the development of intelligent injection molding machines, equipped with advanced technology that monitors and optimizes production processes. Additionally, the company has established a strategic collaboration with leading technology companies, such as Siemens and Bosch Rexroth. The collaboration has enabled Yongming Machinery to integrate advanced technologies in their products, ensuring their injection machines operate at maximum efficiency, quality, and sustainability.In conclusion, Yongming Machinery's latest injection molding machines demonstrate the company's commitment to sustainability, innovation, and customer satisfaction. The machines' energy-efficient features, eco-friendly components, and advanced technology have helped their clients reduce their carbon footprint while increasing their productivity and profitability. Yongming Machinery is poised to continue being a market leader, delivering top-quality products that create a brighter future for all.

Top Quality Bag Making Machine for Eco-Friendly Fabric Bags

Fabric Bag Making Machine Revolutionizes the Textile IndustryIn an era of increasing environmental awareness, the demand for eco-friendly and reusable products is on the rise. This has led to a surge in the production of fabric bags, which are not only stylish but also sustainable alternatives to single-use plastic bags. Recognizing this growing market, the [Company Name] has introduced the latest Fabric Bag Making Machine, which is set to revolutionize the textile industry.The Fabric Bag Making Machine, developed by [Company Name], is a state-of-the-art piece of machinery that is designed to streamline the production process of fabric bags. With its high-speed operation and precise cutting and stitching capabilities, this machine is able to produce a wide range of fabric bags, including tote bags, duffel bags, and backpacks, with exceptional efficiency and quality.One of the key features of the Fabric Bag Making Machine is its versatility. It can process various types of fabrics, including cotton, canvas, jute, and non-woven polypropylene, allowing manufacturers to create a diverse range of bag designs. This flexibility enables businesses to cater to the unique preferences of their customers and tap into different market segments, thus expanding their product offerings and increasing their competitiveness in the industry.In addition to its efficiency and versatility, the Fabric Bag Making Machine is also equipped with advanced automation technology, making it easy to operate and maintain. This not only reduces the need for manual labor but also improves production consistency and reduces the risk of errors, resulting in higher quality products and increased productivity.Moreover, the machine is designed with sustainability in mind. By utilizing eco-friendly materials and optimizing energy consumption, the Fabric Bag Making Machine aligns with the environmentally conscious ethos of the textile industry. This allows manufacturers to not only meet the demand for sustainable products but also reduce their carbon footprint and contribute to a greener and more sustainable future.[Company Name], the pioneering force behind the Fabric Bag Making Machine, is a leading manufacturer of textile machinery with a track record of innovation and excellence. With a strong focus on research and development, the company has continuously introduced cutting-edge technologies and solutions that have redefined the standards of the textile industry.Established [X years ago], [Company Name] has consistently demonstrated its commitment to delivering high-quality and reliable products that meet the evolving needs of its customers. Its unwavering dedication to innovation and customer satisfaction has earned it a strong reputation in the global market, and its products are widely acclaimed for their performance, reliability, and durability.By introducing the Fabric Bag Making Machine, [Company Name] has once again proven its leadership in the industry, providing manufacturers with a game-changing solution that not only enhances their production capabilities but also aligns with the growing demand for sustainable and eco-friendly products.The Fabric Bag Making Machine is set to have a significant impact on the textile industry, empowering manufacturers to capitalize on the rising popularity of fabric bags and meet the increasing demand for environmentally responsible products. As the market continues to embrace sustainable alternatives, the Fabric Bag Making Machine is poised to play a pivotal role in driving the future of bag production and shaping the landscape of the textile industry.

Efficient and Advanced Automatic Packaging Machine: Enhancing Productivity in Packaging Processes

XYZ Company Unveils State-of-the-Art Automatic Packaging Machine[date], [location] - XYZ Company, a leading manufacturer of advanced packaging solutions, has launched its latest innovation, the Automatic Packaging Machine. This cutting-edge technology revolutionizes the packaging industry by enhancing productivity, improving efficiency, and ensuring product quality.The Automatic Packaging Machine, which has been in development for [length of time], is the result of XYZ Company's commitment to continuous improvement and innovation. This advanced machinery is designed to provide a seamless and streamlined packaging process for various industries, including food, pharmaceuticals, and consumer goods.One of the key features of the Automatic Packaging Machine is its versatility. It can handle a wide range of packaging materials, including plastic pouches, aluminum foils, paper bags, and blister packs. This flexibility allows businesses to customize their packaging solutions according to their specific requirements.Moreover, the Automatic Packaging Machine is equipped with state-of-the-art automation technology. It incorporates robotic arms, sensors, and intuitive control systems to automate the packaging process from start to finish. This automation not only cuts down on human error but also increases production speed, allowing businesses to meet demanding deadlines and maximize output.The safety features of the Automatic Packaging Machine are also worth mentioning. It is designed to comply with the highest safety standards, ensuring the protection of both operators and products. The machine is equipped with sensors that detect any abnormalities in the packaging process and immediately halt operations to prevent accidents or inconsistencies.Furthermore, the Automatic Packaging Machine incorporates cutting-edge quality control measures. It utilizes advanced sensors and vision systems to inspect the packaging materials and products at every stage. This real-time monitoring and inspection ensure that only perfectly packaged products are sent out to the market, reducing the risk of recalls and enhancing customer satisfaction.XYZ Company takes pride in its commitment to sustainability, and the Automatic Packaging Machine reflects this philosophy. It is designed to minimize waste and optimize material usage. The machine incorporates recycling mechanisms that efficiently manage excess packaging materials, reducing the environmental impact of the packaging process.With the introduction of the Automatic Packaging Machine, XYZ Company aims to empower businesses with a reliable and efficient packaging solution. The company's dedicated team of engineers and technicians worked tirelessly to develop a machine that embodies their expertise and commitment to excellence."As a leader in the packaging industry, it is our responsibility to provide cutting-edge solutions that address the evolving needs of our customers," said [spokesperson's name], [designation] of XYZ Company. "The Automatic Packaging Machine combines innovation, efficiency, and safety to provide businesses with a competitive edge."The launch of the Automatic Packaging Machine comes at a crucial time when businesses are seeking reliable and efficient packaging solutions to meet the growing demands of the market. XYZ Company's new offering is poised to revolutionize the industry by providing a comprehensive solution that improves productivity, reduces costs, and ensures quality.In conclusion, XYZ Company's Automatic Packaging Machine heralds a new era of packaging technology. With its versatility, automation, safety features, and commitment to sustainability, this innovative solution is set to transform the packaging industry by streamlining operations and enhancing product quality.

Innovative Machinery in Southern China Making Strides in Manufacturing Sector

Guangdong Machine, a leading machinery manufacturer, has recently made a significant impact in the industry with its advanced technological advancements and groundbreaking innovations. The company has been at the forefront of the machinery industry, providing high-quality products and exceptional customer service to clients across the globe. With its dedication to excellence and commitment to innovation, Guangdong Machine has solidified its position as a trusted and reliable partner for businesses in the industrial sector.Established over two decades ago, Guangdong Machine has continuously demonstrated its expertise and ingenuity in the design and production of a wide range of machinery, including CNC machines, vertical machining centers, and milling machines. The company's state-of-the-art manufacturing facilities are equipped with the latest technology and machinery, allowing for the efficient and precise production of high-quality products that meet the diverse needs of its customers.Guangdong Machine's commitment to innovation is reflected in its continuous investment in research and development. The company's team of highly skilled engineers and technicians are constantly exploring new technologies and advancements in the industry to ensure that its products remain at the forefront of innovation. This dedication to innovation has enabled Guangdong Machine to develop advanced machinery that offers enhanced performance, productivity, and efficiency, setting new benchmarks for the industry.In addition to its technological advancements, Guangdong Machine also places a strong emphasis on quality control and assurance. The company adheres to strict quality standards and procedures throughout the manufacturing process to ensure that its products meet the highest levels of quality and reliability. By consistently delivering products of exceptional quality, Guangdong Machine has earned a stellar reputation for excellence and has become a preferred choice for businesses seeking reliable and durable machinery solutions.One of Guangdong Machine's flagship products is its CNC machines, which have garnered widespread acclaim for their precision, reliability, and versatility. Equipped with advanced computer-controlled systems, these machines offer unparalleled accuracy and efficiency, making them ideal for a wide range of applications in industries such as aerospace, automotive, and electronics. The CNC machines from Guangdong Machine have set new industry standards and have become indispensable tools for businesses seeking to enhance their manufacturing capabilities.Another key offering from Guangdong Machine is its vertical machining centers, which are designed to deliver exceptional performance and flexibility. These cutting-edge machines are engineered to perform a wide range of milling, drilling, and tapping operations with precision and speed, making them an excellent choice for manufacturers looking to optimize their production processes and maximize productivity. With their advanced features and cutting-edge technology, the vertical machining centers from Guangdong Machine have become a go-to solution for businesses seeking efficient and reliable machining solutions.In addition to its product excellence, Guangdong Machine is also recognized for its commitment to customer satisfaction. The company places a strong emphasis on understanding the unique needs of its clients and providing tailored solutions that meet their specific requirements. Whether it's providing technical support, troubleshooting issues, or offering customized solutions, Guangdong Machine is dedicated to delivering a superior customer experience that instills confidence and trust in its products and services.As Guangdong Machine continues to make significant strides in the machinery industry, the company remains focused on its mission to drive innovation, exceed customer expectations, and set new standards of excellence. With its unwavering commitment to technological advancements, quality, and customer satisfaction, Guangdong Machine is poised to further solidify its position as a leading force in the machinery industry and continue to shape the future of manufacturing.

Efficient Bag Making Equipment: A Must-Have for Streamlined Production

Title: Revolutionizing Bag Production: Innovative Bag Making Equipment Revolutionizes IndustryIntroduction:In a bid to redefine bag production and meet the changing demands of consumers, a leading manufacturer of bag making equipment has introduced a groundbreaking solution that promises to revolutionize the industry. This cutting-edge technology, developed by a highly skilled team of engineers at the company in question, is poised to transform bag manufacturing processes, enabling businesses to enhance productivity and produce higher-quality bags at an unprecedented scale. Let's delve into the details of this groundbreaking innovation and its potential impact on the bag manufacturing sector.I. Background:Bag making has long been a crucial aspect of many industries, catering to the packaging requirements of various sectors such as retail, food and beverage, agriculture, and more. Traditional bag making equipment often faced challenges related to speed, precision, and flexibility, limiting manufacturers' abilities to keep up with market demands efficiently.Realizing this market need, the engineers at Bag Making Equipment have dedicated years of research and development efforts to create a game-changing solution that addresses these limitations head-on. The new equipment aims to streamline bag production, reducing costs and increasing efficiency for manufacturers across the globe.II. Technological Advancements:The bag making equipment developed by Bag Making Equipment showcases a host of technological advancements aimed at delivering an exceptional bag manufacturing experience. Several notable features set this technology apart from traditional systems, including:1. Precision Engineering: Leveraging cutting-edge design techniques, the equipment has been engineered to ensure precision in every step of the bag-making process. From cutting and sealing to printing and finishing, this equipment guarantees high-quality results, free from defects or imperfections.2. Enhanced Speed and Efficiency: Through the integration of advanced automation systems, the bag making equipment significantly enhances the speed and efficiency of production lines. This allows manufacturers to meet ever-increasing customer demands while reducing production time and costs.3. Versatility and Flexibility: The new equipment allows manufacturers to produce a wide range of bag types and sizes on a single production line. From simple grocery bags to complex packaging solutions, this versatility provides immense flexibility and caters to the diverse needs of various industries.4. Intelligent Control Systems: The state-of-the-art control systems embedded within the equipment allow operators to monitor and adjust critical parameters in real-time. This ensures consistent quality control and minimizes the risk of errors or downtime.III. Potential Impact:The introduction of this advanced bag making equipment could have a transformative impact on the bag manufacturing industry. The benefits it offers include:1. Increased Production Capacity: By optimizing production processes, reducing downtime, and enhancing speed, manufacturers can significantly increase their overall production capacity. This allows them to take on larger orders, meet customer demands promptly, and expand their market reach.2. Enhanced Quality Control: The high precision and intelligent control systems of the equipment facilitate superior quality control throughout the bag-making process, minimizing defects and ensuring consistency. This can help businesses establish a reputation for delivering top-quality bags, boosting customer satisfaction and loyalty.3. Cost Reduction: The efficiency gains achieved through the use of this equipment lead to cost reductions in labor, raw materials, and energy consumption, improving the overall profitability of bag manufacturers. This cost-effectiveness enhances their competitive edge in the market and supports business growth.IV. Conclusion:Bag Making Equipment's cutting-edge bag making technology is poised to redefine bag production processes globally, empowering manufacturers to meet the rapidly evolving demands of customers. By blending precision engineering, automation, and versatility, this equipment promises superior bag quality, increased production capacity, and reduced costs. As bag manufacturers equip themselves with this innovative solution, we can expect the sector to witness substantial growth and opportunities for both businesses and consumers alike.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.

Latest Developments in the Machine Manufacturing Industry

Hengli Machine, a leading manufacturer in the industrial equipment industry, has recently made waves with its latest innovations in machinery technology. Known for their commitment to quality and cutting-edge designs, Hengli Machine has once again proven its dedication to excellence with the release of its newest product line.The company, founded in 1990, has built a strong reputation for producing high-performance machinery for a variety of industries, including automotive, aerospace, and energy. With a focus on research and development, Hengli Machine has consistently pushed the boundaries of what is possible in the world of industrial equipment.The latest product line from Hengli Machine has been designed with an emphasis on efficiency and sustainability. With a growing demand for environmentally friendly solutions, the company has worked tirelessly to create machinery that not only meets exacting performance standards, but also reduces energy consumption and waste. This commitment to sustainability sets Hengli Machine apart from its competitors and has garnered attention from industry professionals and environmental advocates alike.In addition to its focus on sustainable technology, Hengli Machine has also made significant strides in the realm of automation. With advancements in artificial intelligence and robotics, the company has developed machinery that is capable of performing complex tasks with minimal human intervention. This has not only increased productivity and precision but has also improved workplace safety by reducing the need for manual labor in potentially hazardous environments.Recognizing the global impact of their work, Hengli Machine has also invested in expanding its reach beyond its home market in China. With a growing presence in international trade shows and conferences, the company has successfully established partnerships with businesses around the world. This expansion has not only allowed Hengli Machine to share its expertise with a wider audience but has also provided valuable opportunities for collaboration and innovation on a global scale.In a statement, the CEO of Hengli Machine expressed their excitement about the potential impact of their latest product line. "We are proud to introduce our newest machinery, which represents a significant step forward in our ongoing commitment to excellence and sustainability," they said. "We believe that these innovations will not only benefit our customers by improving their operations but will also contribute to a more sustainable future for our planet."The response from industry experts has been overwhelmingly positive, with many praising the company's dedication to innovation and environmental responsibility. "Hengli Machine has once again demonstrated why they are considered a leader in the industrial equipment industry," remarked one industry analyst. "Their latest product line showcases their ability to stay ahead of the curve and provide solutions that address the evolving needs of the market."Looking ahead, Hengli Machine shows no signs of slowing down. With a team of talented engineers and a passion for cutting-edge technology, the company is poised to continue pushing the boundaries of what is possible in the world of industrial machinery. As they continue to expand their global presence and develop new innovations, the future looks bright for Hengli Machine and the industries it serves.In conclusion, Hengli Machine's latest product line represents a significant milestone in the company's long history of innovation and excellence. With a focus on sustainability, automation, and global expansion, Hengli Machine is setting new standards for the industrial equipment industry and shaping the future of manufacturing around the world.

Machine that Makes Bags: A Revolutionary Innovation in Manufacturing

Title: Innovative Bag-Making Machine Revolutionizes the Packaging IndustryIntroduction:In an era where sustainability and eco-consciousness have become key concerns for businesses and consumers alike, the introduction of an innovative bag-making machine is set to revolutionize the packaging industry. The Bag Banane Ki Machine (name removed for neutrality) is a state-of-the-art, automated solution that promises to reduce plastic waste and empower businesses to transition towards more sustainable packaging alternatives. This groundbreaking machine is designed and developed by {} (company name removed), a leading technology company committed to driving positive change through technological advancements.Technological Advancements and Features:The Bag Banane Ki Machine is a cutting-edge piece of technology that combines artificial intelligence, robotics, and innovative manufacturing techniques to produce high-quality bags with great efficiency. With its automated processes, this machine significantly reduces human intervention, thereby minimizing errors and enhancing productivity.The machine's functionality is based on a multi-step process that begins with the precise measurement and cutting of sustainable materials, such as biodegradable plastics or recycled materials, tailored to the desired bag size and shape. Advanced algorithms and machine learning capabilities enable the Bag Banane Ki Machine to maximize production speed while ensuring optimal material usage.Furthermore, the machine employs an intelligent user interface, allowing operators to easily control and monitor the production process. It also includes self-diagnostic features, enabling swift identification and resolution of any technical issues, thus minimizing downtime.Environmental and Economic Benefits:The Bag Banane Ki Machine offers several significant environmental and economic benefits. By utilizing sustainable materials, this innovative technology presents a solution to the pressing issue of plastic waste accumulation. The machine is capable of creating biodegradable bags that effortlessly decompose over time, reducing long-term harm to the environment.Furthermore, the sustainable materials employed by the Bag Banane Ki Machine are often more cost-effective than traditional plastic production. This not only benefits businesses by reducing their packaging costs, but it also encourages the adoption of environmentally friendly packaging options without compromising on quality.Impact on Businesses and Consumers:The availability of the Bag Banane Ki Machine provides businesses with the opportunity to make substantial changes to their packaging strategies. By transitioning to sustainable materials and reducing reliance on traditional plastic bags, brands can enhance their reputation as eco-conscious entities, appealing to a growing consumer demand for sustainable products.Moreover, the machine's ability to produce customizable bags allows businesses to meet specific packaging requirements, further enhancing their product presentation and brand identity. This adaptability increases the versatility of the Bag Banane Ki Machine, making it a valuable asset for a wide range of industries, including retail, food and beverage, and pharmaceuticals.From a consumer perspective, the introduction of sustainable bags manufactured by the Bag Banane Ki Machine aligns with shifting values towards environmentally responsible choices. Consumers are becoming increasingly concerned about single-use plastic pollution and are actively seeking out brands that prioritize sustainability. The availability of eco-friendly bags produced using this innovative machine serves as an assurance to consumers that the brands they support are actively working towards reducing their environmental impact.Conclusion:The introduction of the Bag Banane Ki Machine marks a significant milestone in the packaging industry, revolutionizing the way bags are manufactured. By combining cutting-edge technology, sustainability, and cost-effectiveness, this machine empowers businesses to adopt eco-friendly packaging alternatives while reducing their overall environmental footprint. As the world embraces the urgent need for sustainable practices, the Bag Banane Ki Machine is a pioneering solution that carries the potential to reshape the future of packaging.

High Quality PP Woven Sack Printing Machine offers Efficient Printing Solutions

PP Woven Sack Printing Machine: The Game-Changer in Packaging IndustryThe rise of global trade has given birth to the packaging industry. The need to transport goods from one place to another in a secure and efficient way has led to the development of various packaging materials such as corrugated boxes, plastic bags, and woven sacks. Among these materials, woven sacks have gained immense popularity due to their strength and durability.Woven sacks are widely used to package goods such as cement, fertilizer, and animal feed. They are made from polypropylene (PP) material, which is known for its thermal stability, chemical resistance, and moisture resistance. The demand for woven sacks has been increasing due to their eco-friendliness, convenience, and cost-effectiveness.To meet the growing demand for woven sacks, many packaging companies have invested in PP Woven Sack Printing Machines. These machines have revolutionized the manufacturing process of woven sacks by providing high-quality print on them. The PP Woven Sack Printing Machine uses a rotogravure printing process, which involves the use of a cylinder covered in tiny cells to transfer ink onto the woven sack.The PP Woven Sack Printing Machine offers a wide range of benefits to the packaging industry. It provides high-speed printing with a production capacity of up to 120 bags per minute. It also offers customization options, including the ability to print multiple colors, graphics, and logos on the woven sacks. This allows companies to brand their products effectively and distinguish themselves from their competitors.Moreover, the PP Woven Sack Printing Machine saves time and reduces labor costs. It eliminates the need for manual printing, which is a time-consuming and labor-intensive process. The machine also ensures accuracy and consistency in the printing process, resulting in a uniform and professional-looking product.One company that has invested in PP Woven Sack Printing Machines is {} (remove brand name). The company, founded in {}, has established itself as a leading manufacturer and exporter of PP woven sacks. Its state-of-the-art manufacturing facility is equipped with the latest machinery, including PP Woven Sack Printing Machines.The company's PP Woven Sack Printing Machines are capable of producing high-quality prints that are resistant to water, chemicals, and UV radiation. They are also energy-efficient, using less electricity than traditional printing methods. The machines have contributed to the company's success by providing customers with high-quality products that meet their specific requirements.In addition to PP Woven Sack Printing Machines, {} (remove brand name) also offers a wide range of packaging solutions, including woven sacks, laminated bags, and bulk bags. Its products are widely used in the packaging of agricultural, industrial, and construction products.{}(remove brand name) is committed to providing eco-friendly packaging solutions that meet international standards. The company's woven sacks are 100% recyclable and biodegradable, making them an environmentally responsible choice for packaging goods. The company also follows sustainable practices in its manufacturing processes, such as using renewable energy sources and reducing waste.In conclusion, the PP Woven Sack Printing Machine has emerged as a game-changer in the packaging industry, providing high-quality prints on woven sacks and reducing labor costs. Companies like {} (remove brand name) have invested in these machines to meet the growing demand for woven sacks and provide their customers with high-quality products. As the demand for eco-friendly packaging solutions continues to rise, the PP Woven Sack Printing Machine is expected to play a crucial role in the future of the packaging industry.

Types of Bag Making Machines and Their Applications

Bag Making Machine Revolutionizes Packaging IndustryInnovative technology and superior engineering are transforming the packaging industry, and with the introduction of the latest bag making machine from the leading company in the field, the future has never looked brighter.The bag making machine, which is designed and manufactured by the renowned company, is set to revolutionize the way packaging materials are produced. With its cutting-edge features and state-of-the-art capabilities, this machine is a game-changer for businesses looking to improve their packaging processes and enhance their product offerings.The bag making machine is equipped with advanced automation and precision controls, allowing for high-speed production and extremely accurate bag dimensions. This means that businesses can significantly increase their output and deliver consistently high-quality packaging materials to their customers. The machine also boasts a wide range of customization options, allowing for the production of various types of bags with different sizes, shapes, and materials.One of the most impressive features of the bag making machine is its ability to produce environmentally friendly packaging materials. With the growing demand for sustainable and eco-friendly products, this machine provides businesses with the opportunity to meet these demands and reduce their environmental impact. By using recyclable and biodegradable materials, the machine is helping companies take a step forward in their sustainability efforts and improve their brand image.Furthermore, the bag making machine is designed with efficiency and productivity in mind. It is equipped with innovative technology that minimizes waste and maximizes material utilization, ultimately reducing production costs for businesses. This is a significant advantage for companies looking to improve their bottom line and stay competitive in the market.The company behind the bag making machine has a proven track record of delivering high-quality and reliable packaging solutions to businesses across the globe. With years of experience and a commitment to innovation, the company has become a leading name in the industry.In addition to the bag making machine, the company offers a wide range of packaging equipment and materials, including film extrusion machines, printing machines, and various types of packaging materials. This comprehensive product range allows businesses to find all their packaging needs in one place, simplifying their procurement process and ensuring consistency in quality across their packaging materials.The company also provides exceptional customer support and after-sales service, ensuring that businesses can rely on their equipment to deliver outstanding performance and maintain it with ease. This commitment to customer satisfaction has earned the company a loyal customer base and a strong reputation in the industry.With the introduction of the new bag making machine, the company aims to further solidify its position as a leader in the packaging industry. By providing businesses with cutting-edge technology and superior solutions, the company is driving the industry forward and empowering businesses to achieve new levels of success.In conclusion, the latest bag making machine from the leading company is set to revolutionize the packaging industry. With its advanced technology, sustainable materials, and commitment to efficiency, this machine is a game-changer for businesses looking to improve their packaging processes and meet the evolving demands of the market. As the company continues to innovate and provide exceptional solutions, it is clear that the future of packaging is in good hands.