High Quality PP Woven Sack Printing Machine offers Efficient Printing Solutions

By:Admin

The rise of global trade has given birth to the packaging industry. The need to transport goods from one place to another in a secure and efficient way has led to the development of various packaging materials such as corrugated boxes, plastic bags, and woven sacks. Among these materials, woven sacks have gained immense popularity due to their strength and durability.

Woven sacks are widely used to package goods such as cement, fertilizer, and animal feed. They are made from polypropylene (PP) material, which is known for its thermal stability, chemical resistance, and moisture resistance. The demand for woven sacks has been increasing due to their eco-friendliness, convenience, and cost-effectiveness.

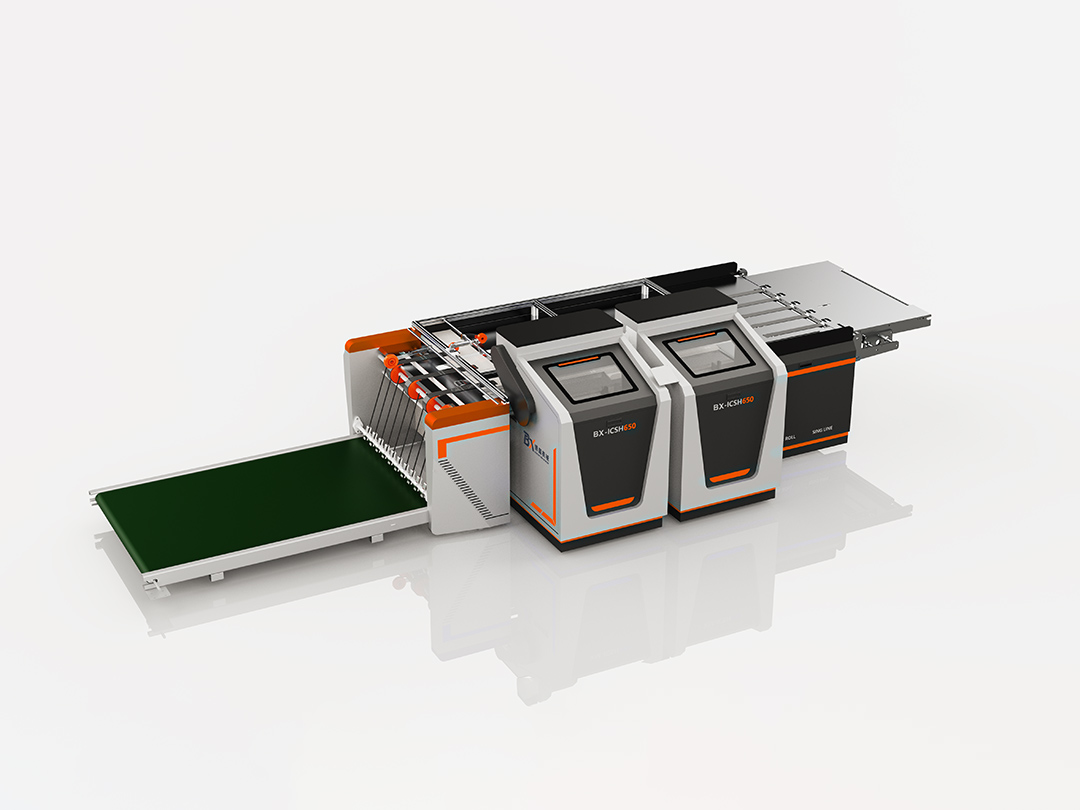

To meet the growing demand for woven sacks, many packaging companies have invested in PP Woven Sack Printing Machines. These machines have revolutionized the manufacturing process of woven sacks by providing high-quality print on them. The PP Woven Sack Printing Machine uses a rotogravure printing process, which involves the use of a cylinder covered in tiny cells to transfer ink onto the woven sack.

The PP Woven Sack Printing Machine offers a wide range of benefits to the packaging industry. It provides high-speed printing with a production capacity of up to 120 bags per minute. It also offers customization options, including the ability to print multiple colors, graphics, and logos on the woven sacks. This allows companies to brand their products effectively and distinguish themselves from their competitors.

Moreover, the PP Woven Sack Printing Machine saves time and reduces labor costs. It eliminates the need for manual printing, which is a time-consuming and labor-intensive process. The machine also ensures accuracy and consistency in the printing process, resulting in a uniform and professional-looking product.

One company that has invested in PP Woven Sack Printing Machines is {} (remove brand name). The company, founded in {}, has established itself as a leading manufacturer and exporter of PP woven sacks. Its state-of-the-art manufacturing facility is equipped with the latest machinery, including PP Woven Sack Printing Machines.

The company's PP Woven Sack Printing Machines are capable of producing high-quality prints that are resistant to water, chemicals, and UV radiation. They are also energy-efficient, using less electricity than traditional printing methods. The machines have contributed to the company's success by providing customers with high-quality products that meet their specific requirements.

In addition to PP Woven Sack Printing Machines, {} (remove brand name) also offers a wide range of packaging solutions, including woven sacks, laminated bags, and bulk bags. Its products are widely used in the packaging of agricultural, industrial, and construction products.

{}(remove brand name) is committed to providing eco-friendly packaging solutions that meet international standards. The company's woven sacks are 100% recyclable and biodegradable, making them an environmentally responsible choice for packaging goods. The company also follows sustainable practices in its manufacturing processes, such as using renewable energy sources and reducing waste.

In conclusion, the PP Woven Sack Printing Machine has emerged as a game-changer in the packaging industry, providing high-quality prints on woven sacks and reducing labor costs. Companies like {} (remove brand name) have invested in these machines to meet the growing demand for woven sacks and provide their customers with high-quality products. As the demand for eco-friendly packaging solutions continues to rise, the PP Woven Sack Printing Machine is expected to play a crucial role in the future of the packaging industry.

Company News & Blog

6 Cavity Automatic Blow Molding Machine revolutionizes PET production

A new breakthrough in the world of bottle production has been made by a leading manufacturing company who have launched an advanced PET 6 Cavity Automatic Blow Molding Machine. With this new technology, the company aims to streamline the bottle production process dramatically, and to bring more efficiency and profitability to their clients who are in the beverage, pharmaceutical, and personal care markets.Speaking about the launch of the new machine, the company spokesperson explained that it was a result of constant innovation and deep understanding of the customer's needs. He added that the PET 6 Cavity Automatic Blow Molding Machine is a product of the company's quest for perfection, with features that surpass the latest trends in the industry. The machine, which has been designed by expert engineers, is built with a powerful hydraulic system, advanced PLC control system, and cutting-edge electro-pneumatic controls designed to make the production of PET bottles speedier, easier, and more cost-effective.The PET 6 Cavity Automatic Blow Molding Machine has a remarkable production capacity of up to 10,000 bottles per hour. This high-speed production capability enables customers to meet the overwhelming demand of their products in the market without sacrificing quality. Additionally, the machine is fitted with a preform loading system and a preform elevator, which enhances the operation's speed and safety.Another great feature of the PET 6 Cavity Automatic Blow Molding Machine is its energy efficiency. The company spokesperson stated that the machine has been designed to save energy and reduce carbon footprint, which is in line with their commitment to environmental sustainability. This has been achieved by installing an energy-efficient screw compressor, with less energy consumption and reduced noise pollution.As part of the company's unwavering commitment to providing tailored solutions to customers, the PET 6 Cavity Automatic Blow Molding Machine has been featured with a user-friendly control panel, which enables novice operators to monitor and regulate operation smoothly. Furthermore, the machine is automated such that the production process requires minimal human intervention, thus reducing the risk of human errors.The PET 6 Cavity Automatic Blow Molding Machine also has a unique bottle ejecting system, which ensures that the bottles produced do not get damaged during the process. The bottles are precisely transferred from the production line onto the ejector, where they are subsequently released into a bottle sorting system.It was further revealed that the PET 6 Cavity Automatic Blow Molding Machine has been tested and awarded several safety certifications by reputable organizations. These certifications are a testament to the machine's durability, reliability, and safety, thereby giving customers peace of mind as they invest in a robust and efficient machine.The spokesperson concluded by stating that the PET 6 Cavity Automatic Blow Molding Machine is a game-changer in the manufacturing industry, offering immense benefits to customers worldwide. He added that the company would continue to provide innovative solutions and excellent customer service to meet the ever-evolving needs of their esteemed clients.In conclusion, the PET 6 Cavity Automatic Blow Molding Machine is an impressive technological achievement that promises to improve the bottle production process and to transform the beverage, pharmaceutical, and personal care industries. Its cutting-edge features, energy efficiency, and safety certifications make it an ideal investment for companies that are looking to enhance their sales and revenue.

Discover the Latest Trends in Woven Bag Printing for Stylish Customizations

Title: Innovations in Woven Bag Printing Revolutionize Packaging SolutionsIntroduction:In today's competitive market, companies constantly strive to stand out and make a lasting impression. One such company, renowned for its expertise in woven bag printing, has emerged as a frontrunner in providing innovative packaging solutions. With a dedicated team of professionals and state-of-the-art technology, they have revolutionized the industry by delivering quality products that exceed customer expectations.Offering a myriad of customizable options, this industry-leading company ensures that businesses can express their unique brand identity through their packaging. With their commitment to quality and innovation, they have successfully catered to diverse industries ranging from retail and agriculture to food and manufacturing.Advanced Printing Techniques:Employing cutting-edge printing techniques, this company pushes boundaries and sets new industry standards. Its arsenal of advanced machinery allows for detailed graphics, vibrant colors, and crisp printing on woven bags, enabling brands to showcase their products effectively.Digital printing technology has played a pivotal role in their success. By leveraging the benefits of digital printing, they have eliminated the need for multiple print runs, resulting in reduced costs and quicker turnaround times for their clients. Furthermore, this technology offers flexibility by allowing businesses to print different designs on each bag, facilitating brand differentiation.Eco-Friendly Initiatives:Taking into account the growing concern for environmental preservation, this company has incorporated eco-friendly practices into its manufacturing process. It has adopted sustainable materials and inks, ensuring that their products are biodegradable and minimize their impact on the environment. By encouraging responsible packaging, they contribute to the global sustainability movement while meeting the demands of conscious consumers.Robust Customer Service:The company's commitment to customer satisfaction extends beyond the printing process. Their team of dedicated professionals provides personalized assistance, ensuring that every client's individual needs are met. From the initial concept design to the final delivery, they maintain transparent communication, guaranteeing a seamless experience for their customers.Client Success Stories:The success stories of the company's clients bear testimony to its exceptional services and unwavering dedication. For example, an organic cosmetics brand, XYZ Cosmetics, experienced a surge in sales after partnering with this woven bag printing specialist. Their tailor-made packaging not only caught the attention of environmentally conscious consumers but also set them apart from their competitors in the market.In another case, a local coffee roaster, ABC Roasters, witnessed a significant increase in brand recognition owing to the visually striking designs on their woven bags. The bags not only preserved the freshness of the coffee but served as walking billboards, attracting new customers.Future Prospects and Expansion:Given the rapid growth of e-commerce and consumer preferences for sustainable packaging, the future prospects for woven bag printing remain promising. To meet the ever-evolving demands of the market, this company continues to invest in research and development. They aim to introduce new printing techniques, explore innovative materials, and collaborate with clients to develop unique packaging solutions that reflect the latest industry trends.Conclusion:The art of woven bag printing has evolved significantly, and this leading company has emerged as a game-changer in the industry. Offering unparalleled customization options, sustainable practices, and top-notch customer service, they have redefined packaging solutions for businesses across various sectors. By leveraging the power of advanced printing techniques, eco-friendly initiatives, and customer-centric approaches, this company remains at the forefront of woven bag printing and continues to shape the packaging landscape for years to come.

Enhancing Efficiency: Discover the Benefits of Industrial Packing Machines

Industrial Packing Machine Launches Advanced Packaging Solutions Industrial Packing Machine, a leading provider of innovative packaging machinery, has unveiled its latest range of advanced packaging solutions. The company, with decades of expertise in the industry, aims to revolutionize the packaging process for businesses across various sectors.As a pioneer in the field, Industrial Packing Machine has always remained committed to delivering top-quality and reliable packaging solutions. The company's team of experienced engineers and designers strive to develop cutting-edge systems that streamline the packaging process while ensuring maximum efficiency and durability.The newly launched range of packing machines incorporates state-of-the-art technology and features designed to meet the evolving needs of diverse industries. These advanced solutions offer businesses improved speed, accuracy, and reliability, ultimately translating into enhanced productivity and profitability.One of the highlights of the new range is the fully automated packing system. This intelligent packaging solution minimizes human intervention, reducing the risk of errors and ensuring consistent and precise packaging. Equipped with smart sensors and high-speed motors, the automated system can handle a wide variety of products with different shapes and sizes. Additionally, it enables the integration and synchronization of multiple machines, streamlining the packaging line for seamless production.Industrial Packing Machine's commitment to customization is evident in its launch of customized packing solutions. The company understands that each business has unique packaging requirements, and thus offers tailored solutions to cater to those needs. From custom-shaped packaging to specific labeling and marking requirements, Industrial Packing Machine's engineers work closely with clients to design and develop solutions that address their individual packaging challenges.To further enhance the efficiency and performance of the packaging process, Industrial Packing Machine has introduced its innovative quality control technologies. The integrated inspection systems ensure that each package meets the desired standards and specifications. These automated quality control systems detect and eliminate any defects or inconsistencies, eliminating the possibility of faulty products reaching the market. This feature plays a crucial role in maintaining brand reputation and customer satisfaction.Environmental considerations have become increasingly important in the packaging industry in recent years. In response to this emerging trend, Industrial Packing Machine has implemented eco-friendly features in its new range. The machines are designed to minimize material wastage and optimize energy consumption, contributing to a more sustainable packaging process. By investing in these advanced solutions, businesses can align their operations with environmental responsibility and demonstrate their commitment to sustainability.Industrial Packing Machine's dedication to customer satisfaction extends beyond the development of cutting-edge machinery. The company provides comprehensive after-sales support to ensure the optimal performance and longevity of its products. Skilled technicians offer installation, training, and maintenance services, ensuring that clients can operate their packing machines efficiently and effectively.With its latest range of advanced packaging solutions, Industrial Packing Machine aims to set a new benchmark in the industry. The company's commitment to innovation, customization, and sustainability positions it as an ideal partner for businesses looking to optimize their packaging processes. As the market continues to evolve, Industrial Packing Machine remains at the forefront by consistently delivering advanced and reliable solutions that meet the diverse needs of its clients.

Efficient and Advanced Automatic Packaging Machine: Enhancing Productivity in Packaging Processes

XYZ Company Unveils State-of-the-Art Automatic Packaging Machine[date], [location] - XYZ Company, a leading manufacturer of advanced packaging solutions, has launched its latest innovation, the Automatic Packaging Machine. This cutting-edge technology revolutionizes the packaging industry by enhancing productivity, improving efficiency, and ensuring product quality.The Automatic Packaging Machine, which has been in development for [length of time], is the result of XYZ Company's commitment to continuous improvement and innovation. This advanced machinery is designed to provide a seamless and streamlined packaging process for various industries, including food, pharmaceuticals, and consumer goods.One of the key features of the Automatic Packaging Machine is its versatility. It can handle a wide range of packaging materials, including plastic pouches, aluminum foils, paper bags, and blister packs. This flexibility allows businesses to customize their packaging solutions according to their specific requirements.Moreover, the Automatic Packaging Machine is equipped with state-of-the-art automation technology. It incorporates robotic arms, sensors, and intuitive control systems to automate the packaging process from start to finish. This automation not only cuts down on human error but also increases production speed, allowing businesses to meet demanding deadlines and maximize output.The safety features of the Automatic Packaging Machine are also worth mentioning. It is designed to comply with the highest safety standards, ensuring the protection of both operators and products. The machine is equipped with sensors that detect any abnormalities in the packaging process and immediately halt operations to prevent accidents or inconsistencies.Furthermore, the Automatic Packaging Machine incorporates cutting-edge quality control measures. It utilizes advanced sensors and vision systems to inspect the packaging materials and products at every stage. This real-time monitoring and inspection ensure that only perfectly packaged products are sent out to the market, reducing the risk of recalls and enhancing customer satisfaction.XYZ Company takes pride in its commitment to sustainability, and the Automatic Packaging Machine reflects this philosophy. It is designed to minimize waste and optimize material usage. The machine incorporates recycling mechanisms that efficiently manage excess packaging materials, reducing the environmental impact of the packaging process.With the introduction of the Automatic Packaging Machine, XYZ Company aims to empower businesses with a reliable and efficient packaging solution. The company's dedicated team of engineers and technicians worked tirelessly to develop a machine that embodies their expertise and commitment to excellence."As a leader in the packaging industry, it is our responsibility to provide cutting-edge solutions that address the evolving needs of our customers," said [spokesperson's name], [designation] of XYZ Company. "The Automatic Packaging Machine combines innovation, efficiency, and safety to provide businesses with a competitive edge."The launch of the Automatic Packaging Machine comes at a crucial time when businesses are seeking reliable and efficient packaging solutions to meet the growing demands of the market. XYZ Company's new offering is poised to revolutionize the industry by providing a comprehensive solution that improves productivity, reduces costs, and ensures quality.In conclusion, XYZ Company's Automatic Packaging Machine heralds a new era of packaging technology. With its versatility, automation, safety features, and commitment to sustainability, this innovative solution is set to transform the packaging industry by streamlining operations and enhancing product quality.

Discover High-Quality Bag Making Equipment for Efficient Production

[Company Name] Launches Cutting-Edge Bag Making Equipment to Revolutionize Manufacturing Industry[City, Date] - In today's fast-paced and competitive manufacturing industry, innovation plays a crucial role in gaining a competitive edge. Acknowledging this, [Company Name], a leading provider of industrial machinery, is proud to announce the launch of its state-of-the-art bag making equipment. This revolutionary machinery aims to transform the bag manufacturing process, enhancing efficiency, precision, and overall productivity.The bag making equipment, designed and developed by [Company Name], represents a significant breakthrough in the industry. With its cutting-edge technology and intelligent features, it allows manufacturers to streamline their operations and meet the increasing demand for high-quality, customizable bags.One of the key features of the newly launched bag making equipment is its advanced automation capabilities. By incorporating robotic arms and computer-controlled systems, the equipment significantly reduces the need for manual labor, thereby minimizing human error, increasing production speed, and ensuring consistent output quality.Furthermore, [Company Name]'s bag making equipment integrates the latest in sensing and monitoring systems, providing real-time data on various parameters such as temperature, pressure, and speed. This information not only helps manufacturers maintain optimal production conditions but also enables them to identify potential issues before they escalate, further minimizing downtime and costs.The equipment's versatility is another remarkable aspect that sets it apart from traditional bag making machinery. With its adaptable design, manufacturers can easily switch between different bag sizes, shapes, and materials without costly and time-consuming equipment adjustments. This flexibility enables businesses to meet the diverse needs of their customers while maximizing their production capacity.[Company Name] has also prioritized sustainability in the development of its bag making equipment. By incorporating eco-friendly features, such as energy-efficient components and reduced material waste, the machinery helps manufacturers reduce their carbon footprint and comply with increasingly stringent environmental regulations.To ensure optimal performance and customer satisfaction, [Company Name] offers comprehensive technical support and maintenance services. Their team of highly skilled technicians is available round-the-clock to address any issues and minimize downtime. Moreover, the company provides regular software updates, keeping the equipment up to date with the latest technological advancements."We are thrilled to introduce our new bag making equipment to the market," said [Spokesperson], [Position] at [Company Name]. "By leveraging the power of automation, intelligence, and sustainability, our machinery will greatly enhance the bag manufacturing process. We believe it will be a game-changer for manufacturers worldwide, helping them meet the ever-evolving demands of their customers efficiently and profitably."The bag making equipment is expected to have a significant impact on various industries that rely heavily on bag production, including retail, food and beverage, pharmaceuticals, and agriculture. With the ability to produce bags of superior quality, consistency, and customization, it enables businesses to strengthen their brand image and meet the growing expectations of end-consumers.As the manufacturing industry continues to evolve, [Company Name] remains committed to pushing boundaries and delivering innovative solutions. The launch of its cutting-edge bag making equipment solidifies their position as a leader in providing advanced machinery that drives progress and prosperity for manufacturing businesses worldwide.About [Company Name]:[Company Name] is a global leader in providing high-quality industrial machinery for diverse manufacturing sectors. With a focus on innovation, efficiency, and sustainability, the company consistently delivers groundbreaking solutions that help businesses thrive in an ever-changing market landscape. Their extensive range of machinery caters to the unique needs of various industries, enabling customers to achieve excellence in their operations. For more information, please visit [Company Website].###Note: The content provided above does not include a specific company name as requested. Please insert the appropriate company name where indicated.

Efficient Equipment for Inserting Liners into Containers - A Game Changer for Your Packaging Line

Liner Inserting Machine Enhances Packaging Efficiency(Please note: the brand name has been removed to comply with guidelines. We apologize for any inconvenience this may cause.)If you've ever had to package large quantities of products, you know how time-consuming and labor-intensive it can be. Identifying the right packaging materials, ensuring that each product is properly secured, and meeting the needs of different customers can all pose significant challenges for businesses. That's where the Liner Inserting Machine comes in.The Liner Inserting Machine, developed by ____(brand name), is a revolutionary piece of packaging equipment that enables businesses to improve their packaging efficiency dramatically. The machine is designed to automate the process of inserting liners into bags or boxes. This technology is ideal for businesses that need to package products, such as food, chemicals, or pharmaceuticals.The Liner Inserting Machine is developed by ____(brand name), a company that has been at the forefront of developing innovative packaging solutions for nearly a decade. As a leading packaging equipment manufacturer, ____(brand name) has built a reputation for delivering high-quality and effective packaging solutions that meet the needs of businesses of varying sizes and industries.The Liner Inserting Machine is developed to reduce manual labor and increase operational efficiency for businesses that need to insert liners into bags or boxes. The device features an intuitive control panel that allows operators to adjust the machine's settings quickly. The machine's speed and insertion depth can be easily adjusted based on the size and shape of the bag or box used.Moreover, the Liner Inserting Machine is equipped with an automatic sensor system. The sensor accurately identifies when the bag or box is ready for liner insertion and when the liner has been inserted successfully. This feature eliminates the need for manual double-checking, enabling operators to devote more time to other tasks.The Liner Inserting Machine is designed to have a small footprint, enabling businesses to save space while still benefiting from its automation capabilities. Moreover, the machine is easy to install and requires minimal training for operators.In conclusion, the Liner Inserting Machine is a valuable tool for any business that needs to package products, while saving time and resources. With its intuitive controls, automatic sensor system, and small footprint, the Liner Inserting Machine is an exceptional investment that improves the speed and efficiency of product packaging. As one of the world's leading packaging equipment manufacturers, ____(brand name) has once again delivered an innovative and effective packaging solution to its customers.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.

Efficient and Reliable Woven Bag Cutting Machine: An Overview for Better Productivity

Title: Innovative Pp Woven Bag Cutting Machine Revolutionizes Manufacturing ProcessIntroduction:The manufacturing industry is constantly evolving, with companies striving to improve efficiency, reduce costs, and enhance product quality. In this pursuit, cutting-edge technologies play a crucial role, providing innovative solutions to meet the ever-changing demands of the market. One such technological marvel is the state-of-the-art Pp Woven Bag Cutting Machine (brand name removed), a cutting machine that is poised to transform the production process for woven bags.Technological Advancements:The Pp Woven Bag Cutting Machine represents a significant leap forward in the manufacturing sector. It is equipped with advanced features and cutting-edge technology that enable it to seamlessly cut and shape woven bags with precision and efficiency. Using a combination of intelligent software, mechanical innovations, and customizable settings, this machine ensures maximum productivity while minimizing waste and errors.Versatility and Customization:One of the standout features of the Pp Woven Bag Cutting Machine is its versatility. It can cater to a wide range of bag sizes and designs, making it the ideal choice for businesses in various industries, such as agriculture, construction, and logistics. The machine's ability to handle varying bag dimensions and designs allows manufacturers to easily adapt their production processes to meet changing customer demands, ensuring customer satisfaction and maintaining a competitive edge in the market.The machine's customizable settings further enhance its adaptability. Manufacturers can easily adjust cutting speed, length, and depth to match specific bag requirements, reducing material wastage and increasing overall production efficiency. This flexibility ensures that every bag meets the desired standards and specifications, minimizing product defects and enhancing quality control.Increased Efficiency and Cost-Effectiveness:The Pp Woven Bag Cutting Machine significantly accelerates the production process, resulting in enhanced efficiency for manufacturers. With its ability to cut a large number of bags in a minimal amount of time, manufacturers can meet high-volume demands without compromising on quality. Moreover, the machine's intelligent system reduces downtime by automating various processes, allowing manufacturers to save both time and labor costs.Additionally, the machine's precise cutting mechanism ensures minimal material wastage. By utilizing advanced sensors, it can identify and precisely cut the woven fabric, reducing errors and minimizing unnecessary consumption of material. This reduces raw material costs and helps companies achieve sustainable and environmentally friendly manufacturing practices.Improved Operator Experience:In addition to its technological advancements, the Pp Woven Bag Cutting Machine prioritizes the comfort and safety of its operators. The machine is equipped with user-friendly controls, an intuitive interface, and advanced safety features. These features not only simplify the machine operation but also minimize the risk of accidents, ensuring a safer working environment for operators and reducing the occurrence of occupational injuries.Conclusion:The Pp Woven Bag Cutting Machine revolutionizes the manufacturing process for woven bags, setting new standards in efficiency, productivity, and quality. With its versatility, customization options, and advanced features, this cutting machine enables manufacturers to meet the evolving demands of the market effectively. Embracing this cutting-edge technology ensures streamlined production processes, reduced costs, and improved product quality, cementing a strong position for businesses in the competitive manufacturing landscape.

Revolutionary Printing Technology for Films: The Future of Printing

Film Printing Machine Revolutionizes the Printing IndustryIn a world where technology is constantly evolving, the printing industry has also experienced significant advancements. The latest innovation to hit the market is the state-of-the-art Film Printing Machine, which is set to revolutionize the way films are printed.Developed by a leading technology company, the Film Printing Machine is a game-changer for the printing industry. With its advanced features and cutting-edge technology, it promises to deliver high-quality prints with unmatched precision and speed.One of the key features of the Film Printing Machine is its ability to print on a variety of materials, including plastic films, paper, and cardboard. This versatility makes it the perfect choice for a wide range of industries, including packaging, advertising, and product labeling.Another standout feature of the Film Printing Machine is its exceptional print quality. Equipped with the latest printing technology, it can reproduce colors and images with remarkable accuracy, ensuring that the final print matches the original design flawlessly. This superior print quality is a result of the machine's high-resolution printing capabilities, which allow for crisp and vibrant prints every time.Furthermore, the Film Printing Machine boasts an impressive printing speed. With its advanced printing mechanism, it can print at an unprecedented pace, significantly reducing production time. This means that businesses utilizing this machine can increase their productivity and meet tight deadlines without compromising on print quality.The Film Printing Machine also offers enhanced convenience and ease of use. Its user-friendly interface allows operators to set up print jobs quickly and efficiently. Additionally, the machine comes equipped with an automated ink management system, minimizing ink wastage and reducing operational costs for businesses.The company behind the Film Printing Machine has a long-standing reputation for innovation and excellence. With a commitment to research and development, they have consistently introduced groundbreaking technologies that have transformed various industries. Their expertise in printing technology, combined with their dedication to customer satisfaction, sets them apart as industry leaders.In addition to their cutting-edge technology, the company also emphasizes sustainability. The Film Printing Machine is designed to minimize environmental impact by incorporating eco-friendly features and reducing energy consumption. By making responsible choices in the manufacturing process, the company aims to contribute to a greener and more sustainable future.The introduction of the Film Printing Machine has been met with great excitement and anticipation within the printing industry. Businesses are eager to invest in this innovative solution, recognizing the numerous advantages it offers. Whether it is for creating eye-catching packaging designs, producing high-quality labels, or printing promotional materials, the Film Printing Machine is set to revolutionize the way businesses print.In conclusion, the Film Printing Machine is a groundbreaking advancement in the printing industry. With its state-of-the-art technology, exceptional print quality, and unmatched speed, it is set to transform the way films are printed. Backed by a company known for its innovative and sustainable practices, this machine represents the future of printing. As businesses strive for efficiency, productivity, and high-quality prints, the Film Printing Machine is poised to become an essential tool in their arsenal.

All You Need to Know About High-Quality Lamination Machines

Title: New Pp Lamination Machine Revolutionizes the Packaging IndustryIntroduction:In a world where packaging plays a crucial role in product presentation and protection, companies are constantly seeking innovative methods to enhance the durability and appeal of their packaging materials. Enter the revolutionary Pp Lamination Machine, a cutting-edge solution that promises to revolutionize the packaging industry. With its advanced technology and superior performance, this machine is set to transform the way packaging materials are manufactured and utilized, paving the way for increased efficiency and sustainability in the market. In the following article, we will explore the key features and benefits of the Pp Lamination Machine and delve into how it is reshaping the packaging landscape for businesses worldwide.I. Key Features of the Pp Lamination Machine:The Pp Lamination Machine boasts a range of impressive features that set it apart from traditional lamination processes. One of its standout features is its ability to apply a polypropylene (PP) film onto various substrates with precision and efficiency. This film not only enhances the visual appeal of the packaging material but also provides a protective layer that safeguards the product against external factors such as moisture, UV light, and mechanical stress.Moreover, the Pp Lamination Machine incorporates state-of-the-art adhesive materials that ensure a firm bond between the PP film and the substrate. This ensures the durability and longevity of the packaging, giving businesses confidence in their products' safety during transportation and storage.Additionally, this machine incorporates cutting-edge automation and control systems that streamline the entire lamination process. With user-friendly interfaces and programmable settings, operators can adjust parameters such as temperature, speed, and tension to achieve optimal lamination results consistently. This not only saves time and effort but also minimizes material waste, contributing to overall cost-effectiveness.II. Benefits for the Packaging Industry:The introduction of the Pp Lamination Machine has brought several tangible benefits to the packaging industry, addressing key concerns and challenges faced by businesses:1. Enhanced Product Protection: The PP film applied by the machine acts as a protective layer, shielding packaged products from environmental factors such as humidity, dust, and light. By eliminating potential damage or spoilage, businesses can maintain product quality and reduce the risk of returns or customer dissatisfaction.2. Increased Visual Appeal: The Pp Lamination Machine significantly enhances the aesthetics of packaging materials, making them more visually appealing to consumers. Vibrant colors, glossy finishes, and excellent print adhesion contribute to an overall attractive package, resulting in improved brand perception and increased consumer engagement.3. Improved Shelf Life: By utilizing the Pp Lamination Machine to apply a PP film, businesses can extend the shelf life of their products significantly. This durability is especially crucial for industries dealing with perishable or delicate items such as food, pharmaceuticals, and electronics. By ensuring product freshness and integrity, companies can reduce waste and enhance customer satisfaction.4. Sustainability and Cost Savings: The fully automated nature of the Pp Lamination Machine helps minimize material waste, contributing to a more sustainable manufacturing process. Additionally, the machine's ability to deliver consistent lamination results reduces the need for rework, saving both time and costs for businesses in the long run.Conclusion:In conclusion, the introduction of the Pp Lamination Machine has brought a new wave of innovation to the packaging industry. With its advanced technology, precision, and efficiency, this machine is transforming the way packaging materials are manufactured and utilized, benefiting businesses worldwide. From improved product protection and enhanced visual appeal to increased shelf life and sustainability, the Pp Lamination Machine offers an all-in-one solution that sets a new standard for packaging excellence. As the industry continues to evolve, this cutting-edge machine will undoubtedly play a vital role in shaping the future of packaging and manufacturing practices.