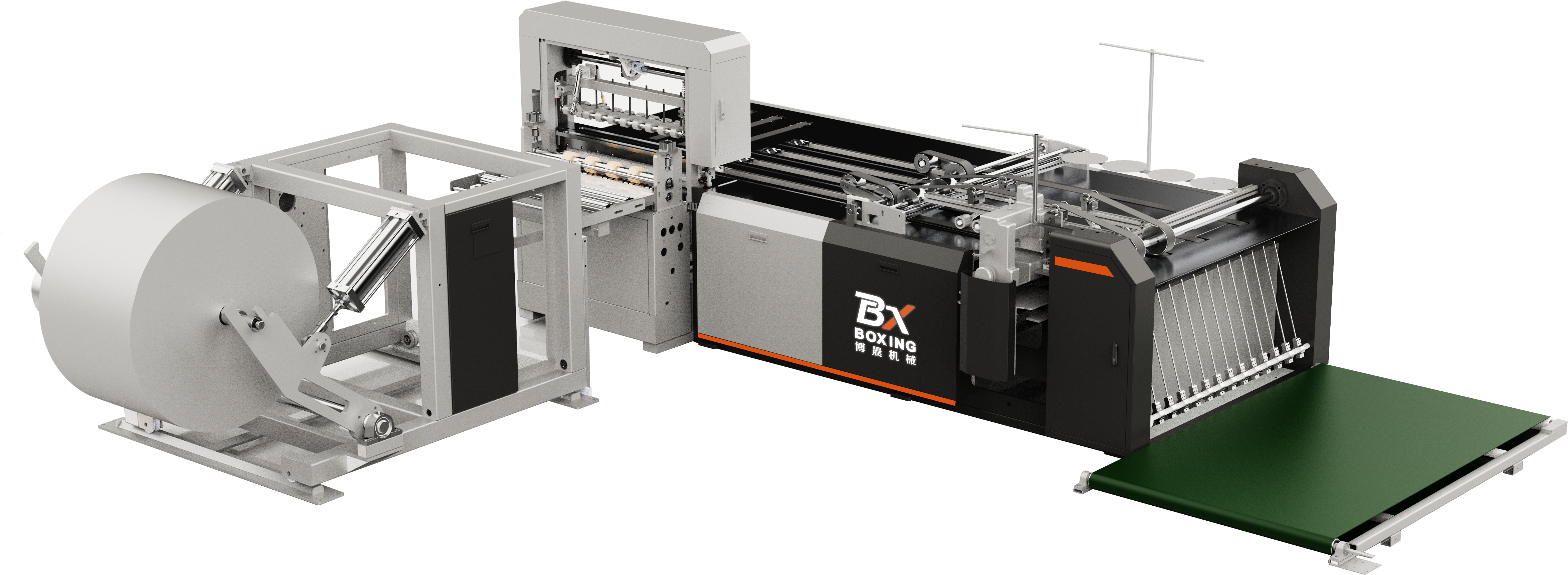

High-Quality Bag Making Equipment for Efficient Production

By:Admin

The Bag Making Equipment company was founded on the principles of innovation, reliability, and customer service. They have been committed to providing their clients with the latest technology and the most reliable machinery on the market. With a team of experienced engineers and technicians, the company has been able to develop cutting-edge equipment that is setting new industry standards.

One of the company's flagship products is their state-of-the-art bag making machine, which is designed to produce high-quality bags with precision and efficiency. This machine is equipped with advanced features such as automatic tension control, servo motor drive system, and user-friendly interface, making it easy to operate and maintain. These features not only ensure the production of durable and reliable bags, but also contribute to increased productivity and reduced production costs for their clients.

In addition to their leading bag making machine, the company also offers a wide range of auxiliary equipment to complement their production line. This includes equipment for printing, cutting, and sealing, as well as various accessories to customize the production process according to the specific needs of their clients. By providing a comprehensive solution for bag making, the company has become a one-stop shop for all packaging needs.

Furthermore, Bag Making Equipment understands the importance of after-sales service and support for their clients. They have established a dedicated team of technicians and support staff to provide timely and efficient support to their customers. This commitment to customer satisfaction has earned them a reputation for reliability and trustworthiness in the industry.

The company's success can also be attributed to their strong focus on research and development. They are constantly investing in new technologies and methodologies to improve their machinery and stay ahead of the competition. By keeping a pulse on industry trends and customer feedback, they have been able to consistently innovate and improve their products, ensuring that they remain at the forefront of the market.

With a strong emphasis on quality, reliability, and customer satisfaction, Bag Making Equipment has become a trusted name in the packaging industry. Their commitment to excellence and innovation has set them apart from their competitors, and they continue to raise the bar for what can be achieved in bag making machinery.

As the company looks to the future, they remain dedicated to their core values of innovation, reliability, and customer service. They are poised to continue revolutionizing the packaging industry with their cutting-edge technology and unwavering commitment to excellence. With their ongoing focus on research and development, along with their dedication to customer satisfaction, they are well positioned to maintain their leadership in the bag making equipment market for years to come.

Company News & Blog

High-Quality Flexo Print Machine for Efficient Printing Operations

Flexo Print Machine Revolutionizing the Printing IndustryThe printing industry has seen significant advancements in technology over the years, with the latest innovation being the Flexo Print Machine. This revolutionary machine has been making waves in the industry for its ability to produce high-quality prints on various materials, including paper, cardboard, and plastic.The Flexo Print Machine, developed by a leading printing equipment manufacturer, has been designed to meet the growing demands of the packaging and label printing industry. With its state-of-the-art technology and precision engineering, the machine has set new standards for print quality, efficiency, and versatility.One of the key features of the Flexo Print Machine is its ability to produce vibrant and sharp prints on a wide range of substrates. This versatility has made it a popular choice for packaging and label printing companies, as it allows them to meet the diverse needs of their clients. The machine also offers fast and efficient printing, maximizing productivity and reducing turnaround times.In addition to its printing capabilities, the Flexo Print Machine is also renowned for its cost-effectiveness. The machine’s efficient use of ink and other consumables helps printing companies to reduce their operating costs. This is particularly beneficial for small to medium-sized printing businesses that are looking to improve their bottom line.Furthermore, the Flexo Print Machine is designed for ease of use and maintenance, reducing downtimes and minimizing the need for costly repairs. Its user-friendly interface and intuitive controls make it accessible to operators of varying skill levels, streamlining the printing process and ensuring consistent, high-quality results.The company behind the Flexo Print Machine has a long-standing reputation for delivering cutting-edge printing equipment to the industry. With a team of skilled engineers and designers, the company has consistently pushed the boundaries of innovation, resulting in a portfolio of industry-leading products.In addition to its technical expertise, the company also places a strong emphasis on customer satisfaction. It offers comprehensive training and after-sales support to ensure that its clients are able to maximize the potential of their printing equipment. This commitment to customer service has established the company as a trusted partner to printing businesses around the world.The Flexo Print Machine is just one example of the company’s dedication to advancing the printing industry. With a focus on continuous improvement and a forward-looking approach, the company is well-positioned to drive further innovation and shape the future of printing technology.As the demand for high-quality packaging and label printing continues to grow, the Flexo Print Machine is poised to play a pivotal role in meeting these needs. Its combination of exceptional print quality, efficiency, and cost-effectiveness makes it a valuable asset to any printing business looking to stay ahead of the curve.In conclusion, the Flexo Print Machine represents a significant leap forward for the printing industry. With its unparalleled printing capabilities, user-friendly design, and cost-effective operation, it has quickly become a game-changer for packaging and label printing. As the company continues to lead the way in printing technology, the Flexo Print Machine is set to revolutionize the industry for years to come.

Advanced Technology for Laminating Pp Woven Sacks for Enhanced Durability

Title: State-of-the-Art Pp Woven Sack Lamination Machine: Revolutionizing the Packaging IndustryIntroduction:As the packaging industry continues to evolve, advancements in machinery and technology have become crucial for meeting the increasing demands of the global market. One such innovation, the Pp Woven Sack Lamination Machine, has garnered significant attention for its ability to transform the way packaging materials are manufactured. This state-of-the-art machine, developed by an industry-leading manufacturer, aims to enhance the efficiency, durability, and versatility of woven sacks, propelling the packaging industry into a new era.Enhancing Efficiency:Efficiency is a key factor in any manufacturing process, and the Pp Woven Sack Lamination Machine excels in this aspect. Through its seamless integration of advanced automation technology, this machine streamlines the production process, enabling manufacturers to meet consumer needs more quickly and efficiently. With the ability to handle large volumes of woven sacks, it significantly reduces production time, minimizing costs and increasing output.Moreover, the machine's cutting-edge control system provides real-time monitoring and adjustment of various parameters, ensuring accurate and consistent lamination. This precise control enhances product quality, reducing wastage and increasing customer satisfaction.Durability and Strength:Packaging materials must possess the necessary durability and strength to protect the goods they hold. The Pp Woven Sack Lamination Machine tackles this challenge with its groundbreaking lamination process. By fusing multiple layers of polypropylene (PP) woven fabric, the machine creates a robust and resilient final product.This lamination process significantly enhances the strength and tear resistance of the woven sacks, ensuring that even the most challenging packaging requirements are met. From heavy-duty industrial goods to perishable food products, the sacks produced by this machine can withstand various environmental conditions, providing ultimate protection throughout the supply chain.Versatility and Customization:In today's dynamic market, packaging solutions must be adaptable and customizable to cater to diverse industries and their unique requirements. The Pp Woven Sack Lamination Machine offers incredible versatility, allowing manufacturers to produce a wide range of woven sacks with varying sizes, shapes, and designs.With its ability to integrate different types of materials, such as BOPP films or non-woven fabrics, into the lamination process, the machine enables manufacturers to create customized packaging solutions tailored to their customers' specific needs. This flexibility strengthens brands' market presence by enhancing product visibility and appeal.Environmental Sustainability:In an era of heightened environmental consciousness, the Pp Woven Sack Lamination Machine adheres to eco-friendly principles. By utilizing sustainable raw materials and implementing energy-efficient processes, it minimizes the carbon footprint associated with packaging production.Furthermore, the machine's ability to produce reusable, recyclable, and biodegradable woven sacks contributes to a more sustainable packaging ecosystem, reducing the environmental impact of discarded materials. This commitment to sustainability aligns with changing consumer expectations and positions manufacturers as responsible corporate citizens.Conclusion:The advent of the Pp Woven Sack Lamination Machine represents a significant milestone in the packaging industry. With its ability to enhance efficiency, durability, versatility, and environmental sustainability, this state-of-the-art machine revolutionizes the way woven sacks are manufactured. By integrating advanced automation and control systems, manufacturers can optimize their production processes, ensuring timely delivery of high-quality packaging materials.As the packaging industry continues to evolve and adapt to changing consumer demands, the Pp Woven Sack Lamination Machine serves as a beacon of innovation and progress. Its versatile nature enables manufacturers to create customized solutions while prioritizing sustainability. With this advanced machinery, the packaging industry is set to witness substantial growth and meet the ever-evolving needs of the global market.

Innovative Paper Packaging Machine Streamlines Production Process

In the world of packaging, paper has long been a preferred material due to its environmental friendliness and versatility. As concerns about sustainability and environmental impact continue to grow, the demand for paper packaging is only expected to increase. To meet this demand, {Company}, a leading packaging machinery manufacturer, has introduced a new Paper Packaging Machine that is set to revolutionize the industry.With a long history of providing innovative and efficient packaging solutions, {Company} has established itself as a trusted name in the industry. The company is known for its commitment to quality, reliability, and customer satisfaction. With the introduction of the new Paper Packaging Machine, {Company} is once again demonstrating its dedication to meeting the evolving needs of its customers and the industry as a whole.The new Paper Packaging Machine is a state-of-the-art piece of equipment designed to streamline the packaging process for paper-based products. Whether it's for food packaging, pharmaceuticals, cosmetics, or any other industry that relies on paper packaging, this machine is capable of handling a wide range of products with precision and efficiency. Its advanced technology allows for quick and seamless packaging, ensuring that products are not only well-protected but also presented in an attractive and professional manner.One of the standout features of the new Paper Packaging Machine is its versatility. It is designed to accommodate various sizes and shapes of products, making it an ideal solution for businesses with diverse packaging needs. Additionally, the machine is equipped with advanced automation and intelligent control systems, which not only enhance its performance but also make it easy to operate and maintain.In addition to its impressive capabilities, the new Paper Packaging Machine is also designed with sustainability in mind. {Company} understands the growing importance of eco-friendly packaging solutions and has incorporated features into the machine that minimize waste and energy consumption. This aligns with the company's commitment to environmental responsibility and provides its customers with a packaging solution that meets their sustainability goals.Furthermore, {Company} is offering comprehensive support and servicing for the new Paper Packaging Machine. With a team of experienced technicians and customer service professionals, the company is dedicated to ensuring that its customers can maximize the performance and longevity of their packaging equipment. This commitment to customer support further demonstrates {Company}'s dedication to providing a complete and reliable packaging solution.The introduction of the new Paper Packaging Machine represents a significant advancement for {Company} and the packaging industry as a whole. With its cutting-edge technology, versatility, and focus on sustainability, the machine is poised to become a game-changer for businesses looking to enhance their packaging processes. As the demand for paper packaging continues to rise, {Company} is well-positioned to meet the needs of its customers and drive innovation in the industry.In conclusion, {Company}'s new Paper Packaging Machine is a testament to the company's ongoing commitment to excellence and innovation. By combining advanced technology, versatility, and sustainability, {Company} has once again raised the bar for packaging machinery. As businesses increasingly turn to paper packaging, this new machine is set to play a crucial role in helping them meet their packaging needs efficiently and responsibly. With its extensive support and servicing, {Company} is not only providing a cutting-edge solution but also ensuring that its customers can continue to rely on its expertise and dedication to quality.

High-Performance Cutting and Sewing Machine: A Must-Have for Your Sewing Projects

The Cutting and Sewing Machine industry has experienced numerous technological advancements in recent years, and one company that has been leading the way in innovation is {}. Founded in 1990, {} has become a global leader in the manufacturing and distribution of cutting and sewing machines for a wide range of industries including apparel, automotive, upholstery, and home textiles.With a commitment to quality, innovation, and customer satisfaction, {} has developed a reputation for producing cutting-edge machinery that meets the evolving needs of the global market. The company's dedication to research and development has resulted in the creation of some of the most advanced and efficient cutting and sewing machines available today.One of {}'s flagship products is the {}, a state-of-the-art cutting and sewing machine that has revolutionized the industry. This groundbreaking machine is equipped with cutting-edge technology that allows for precision cutting and sewing, resulting in higher efficiency and productivity for its users. The machine's user-friendly interface and advanced automation features make it an invaluable tool for manufacturers looking to streamline their production processes.In addition to the {}, {} also offers a wide range of cutting and sewing machines designed to cater to the specific needs of different industries. Whether it's a high-speed cutting machine for the apparel industry or a heavy-duty sewing machine for upholstery, {} has a comprehensive line-up of products to meet the diverse requirements of its customers.Furthermore, {} prides itself on its commitment to customer satisfaction by providing top-notch after-sales service and support. The company has built a global network of service centers and technical support teams to ensure that its customers have access to the assistance they need, whenever they need it. This dedication to customer care has earned {} a loyal and satisfied customer base that continues to grow year after year.As part of its efforts to stay at the forefront of the industry, {} is constantly investing in research and development to improve its existing products and develop new, cutting-edge solutions. The company's team of engineers and experts are always seeking new innovations and technologies to integrate into their cutting and sewing machines, ensuring that {} remains a leader in the industry for years to come.In addition to its commitment to innovation and customer satisfaction, {} is also dedicated to environmental sustainability. The company is constantly seeking ways to minimize its environmental impact through the use of energy-efficient manufacturing processes and the development of eco-friendly products. By prioritizing sustainability, {} is not only contributing to a healthier planet, but also helping its customers reduce their carbon footprint.Looking ahead, {} is poised to continue its growth and success in the cutting and sewing machine industry. With a focus on innovation, customer satisfaction, and environmental responsibility, the company is well-positioned to meet the evolving needs of the global market and maintain its position as a leader in the industry.In conclusion, with its cutting-edge technology, commitment to customer satisfaction, and dedication to environmental sustainability, {} has established itself as a prominent player in the cutting and sewing machine industry. As the company continues to innovate and expand its product offerings, it is expected to remain a driving force in the industry for many years to come.

New Innovative Print Machine Boosts Efficiency and Productivity in the Market

Title: Advanced Print Machine Revolutionizes CI Industry with Cutting-Edge TechnologyIntroductionIn a significant breakthrough for the continuous inkjet (CI) printing industry, a leading technology company has unveiled its latest innovation, an advanced CI print machine. This groundbreaking new device, with its state-of-the-art features and cutting-edge technology, promises to revolutionize the printing and packaging sector. By offering improved efficiency, environmental sustainability, and enhanced print quality, this revolutionary CI print machine sets a new standard in the industry.Deep DiveThe introduction of this game-changing CI print machine comes as a result of extensive research and development efforts by the company's team of highly skilled engineers. By successfully integrating advanced technologies and innovative features, this print machine is tailored to meet the diverse needs of the printing industry.With an emphasis on sustainability, the new CI print machine boasts substantial improvements in terms of energy consumption and resource efficiency. By implementing intelligent power management systems, the machine achieves a significant reduction in power consumption, resulting in lower operating costs for businesses while minimizing its environmental impact.Furthermore, the print machine utilizes a cutting-edge ink formulation that maximizes ink usage, reducing ink wastage and promoting sustainability in the printing process. The intelligently designed ink system ensures precise ink control, enabling high-quality prints while minimizing ink consumption.Another groundbreaking feature of this CI print machine is its enhanced print speed. With its advanced print head technology, the machine achieves uninterrupted high-speed printing, leading to improved productivity and reduced production timelines. This allows businesses to meet tight deadlines and high-volume demands, giving them a competitive edge in the market.Moreover, the CI print machine is equipped with intelligent sensors that detect and correct printing errors in real-time, ensuring consistent print quality throughout the production process. This technology reduces the need for reprints, thus minimizing cost and material waste. The resulting print quality surpasses the industry norm, providing businesses with impressive visual appeal and accuracy in their printed materials.The user-friendly interface of the CI print machine further enhances its appeal to businesses. With its intuitive controls and simplified operation, it offers effortless set-up and printing processes. The built-in troubleshooting system provides easy diagnosis and resolution of any technical issues, reducing downtime and maximizing efficiency.In addition to its innovative features, the CI print machine is designed to seamlessly integrate into existing production lines, making it a versatile solution for businesses of all sizes. This compatibility ensures a smooth transition to the advanced print technology without requiring a complete overhaul of the existing infrastructure.The CI print machine is set to create a significant impact in the packaging industry, particularly in applications such as food and beverage packaging, pharmaceutical labeling, and product branding. Its ability to deliver consistently high-quality prints, combined with its environmentally friendly features, makes it an ideal choice for companies aiming to enhance brand value and consumer satisfaction.ConclusionWith its advanced technology and groundbreaking features, the new CI print machine is poised to revolutionize the printing and packaging industry. The integration of sustainability, increased efficiency, and superior print quality sets a new industry standard. Businesses can now benefit from reduced costs, enhanced productivity, and improved environmental sustainability, positioning themselves at the forefront of their respective markets. The launch of this groundbreaking CI print machine undoubtedly proves the company's commitment to technological innovation and its dedication to providing cutting-edge solutions to meet evolving industry needs.

High-Quality Woven Sack Printing Machine for Efficient Packaging

Woven Sack Printing Machine: A Revolutionary Addition to the Packaging IndustryAs the demand for durable and versatile packaging solutions continues to rise, the need for advanced and efficient printing technology becomes increasingly important. With this in mind, {Company Name}, a leading manufacturer of packaging machinery, has introduced a state-of-the-art Woven Sack Printing Machine that promises to revolutionize the industry.The Woven Sack Printing Machine is designed to meet the growing needs of the packaging industry by providing a high-speed, high-quality printing solution for woven sacks, which are commonly used for packaging various products including grains, fertilizers, chemicals, and cement. This innovative machine boasts advanced features that ensure superior print quality, precise registration, and fast production speeds, making it an ideal choice for businesses looking to enhance their packaging capabilities.One of the key highlights of the Woven Sack Printing Machine is its ability to deliver vibrant and long-lasting prints on woven sacks, thanks to its advanced printing technology and high-quality ink system. This ensures that the packaging not only serves its primary function of protecting the contents but also serves as a powerful marketing tool, effectively communicating brand messages and product information to consumers.Furthermore, the machine offers exceptional versatility, allowing businesses to customize their packaging with various designs, logos, and text, thus catering to the diverse needs of different industries. Its user-friendly interface and intuitive controls make it easy to operate and maintain, reducing downtime and increasing productivity for businesses.{Company Name} has a long-standing reputation for delivering cutting-edge packaging solutions, and the introduction of the Woven Sack Printing Machine further solidifies its position as an industry leader. With a focus on innovation, quality, and customer satisfaction, the company has continuously strived to develop advanced machinery that meets the evolving needs of the packaging industry.The Woven Sack Printing Machine is a testament to {Company Name}'s commitment to providing top-of-the-line packaging solutions that empower businesses to stay ahead of the competition. By investing in this innovative machine, businesses can streamline their packaging processes, improve their branding efforts, and ultimately enhance their overall competitiveness in the market.In addition to its advanced machinery, {Company Name} also offers comprehensive support services including installation, training, and technical assistance, ensuring that customers can maximize the benefits of their investment in the Woven Sack Printing Machine. This commitment to customer satisfaction further sets the company apart in the industry, making it a preferred partner for businesses looking to upgrade their packaging capabilities.With the introduction of the Woven Sack Printing Machine, {Company Name} is set to drive further growth and innovation in the packaging industry, setting new benchmarks for quality, efficiency, and performance. This cutting-edge machine promises to transform the way businesses approach packaging, helping them meet the ever-changing demands of the market while staying ahead of the competition.In conclusion, the Woven Sack Printing Machine from {Company Name} represents a significant advancement in the packaging industry, offering businesses a powerful tool to enhance their packaging capabilities and drive their business success. With its advanced features, superior print quality, and unmatched versatility, this innovative machine is poised to become a game-changer for businesses seeking to elevate their packaging standards and stay ahead in today's competitive market.

New Technology Innovations in Printing Woven Bags

Woven bag printing is a crucial aspect of the packaging industry. The ability to print on woven bags is an important step in branding and marketing products. It's an efficient way of advertising the products to prospective clients and customers. Woven bag printing allows the printing of specific logos, graphics, colors, and images that can promote a brand's message.As industries continue to emerge, the trend in woven bag printing has risen. Many companies are now investing in high-quality printed woven bags to make sure their products have unique packaging. The woven bag printing service has been a booming industry in recent years, promoting products and carrying company branding. A lot of companies are now turning to this kind of service to make an impact in the market.Over the years, the advancement in technology has transformed every industry, including the packaging industry. The manufacturers of woven bags have been pioneers in the woven bag printing industry. Most of them now use modern digital printing machines for printing on the woven bags. Digital printing ensures efficient production of high-quality woven bags that can be customized according to the customer's specifications.One leading company that specializes in woven bag printing is {Brand Name Removed}, a company that has a reputed track record of providing high-quality woven bags. Established many years ago, {Brand Name Removed} is a pioneer in the manufacturing and printing of woven bags. The company prides itself in providing the best and most innovative solutions to their clients in the packaging industry.{Brand Name Removed} is a customer-centric company that ensures customer satisfaction is achieved with every job. The company can customize their woven bags to suit their customer's requirements, including printing company logos and designs on the bags. Their state-of-the-art digital machines are equipped with high-resolution printing capabilities to produce clear and vibrant images and texts on the woven bags.{Brand Name Removed} has a team of skilled designers that ensure all the client's needs are met. The design team uses the latest design software in preparing the layout and design of the bags. Before mass production, the client is presented with a prototype of their desired design. The prototype helps the client to ensure that they are satisfied with the final design before mass production commences.Aside from woven bag printing, {Brand Name Removed} has a diverse range of products in their product line up. The products range from woven polypropylene bags, laminated bags, and sack bags that come in different sizes and shapes. The company aims to provide customizable, cost-effective, and eco-friendly packaging solutions to their clients.Another aspect of {Brand Name Removed} is their commitment to eco-friendliness. They have embraced environmentally friendly and green technology in their production process. They are committed to producing sustainable packaging solutions that pose no harm to the environment.Finally, {Brand Name Removed} has implemented strict quality control measures to ensure that the company complies with the required industry standards. The company's production line undergoes rigorous quality checks at every stage of the production process from raw materials to finished products.In summary, woven bag printing is an essential aspect of the packaging industry. The ability to print on woven bags ensures that companies can promote their brand and make an impact in the market. {Brand Name Removed}, a pioneer in the woven bag printing industry, provides high-quality woven bags that are customizable to client's requirements. The company is customer-focused, environmentally conscious, and committed to producing quality products in the packaging industry.

Increase Efficiency with Industrial Machinery: A Complete Guide

Machine Industrial, a leading provider of industrial machinery and equipment, has recently announced the launch of their new state-of-the-art automated assembly line. The company is known for its innovative solutions in the manufacturing industry and this new assembly line is expected to revolutionize the production process for a wide range of industries.The new assembly line incorporates the latest technology in robotics and automation, allowing for a more efficient and streamlined production process. This means that manufacturers will be able to increase their output while reducing labor costs, ultimately leading to higher profitability.Machine Industrial has always been at the forefront of technological advancements in the industry, and this new automated assembly line is a testament to their commitment to innovation. The company has a long history of providing quality machinery and equipment to manufacturers across the globe, and this new development is expected to further solidify their position as a leader in the industry.In addition to the new assembly line, Machine Industrial also offers a wide range of other industrial machinery and equipment, including CNC machines, industrial robots, and automation systems. Their products are known for their reliability, durability, and efficiency, making them the go-to choice for manufacturers looking to improve their production processes.Machine Industrial has a team of highly skilled engineers and technicians who are dedicated to providing top-notch service and support to their customers. They work closely with each client to understand their unique needs and provide customized solutions to help improve their manufacturing processes.The company has a strong reputation for delivering on their promises and consistently exceeding customer expectations. Their commitment to excellence and their ability to stay ahead of the curve in terms of technological advancements have earned them the trust and loyalty of customers around the world.Machine Industrial is also committed to sustainability and environmental responsibility. They strive to develop and promote solutions that help reduce waste and improve energy efficiency, ultimately leading to a greener and more sustainable manufacturing industry.The launch of the new automated assembly line is just the latest example of Machine Industrial's dedication to innovation and progress. The company continues to invest in research and development to stay at the forefront of the industry, and they are constantly exploring new ways to improve their products and services.As the manufacturing industry continues to evolve and grow, Machine Industrial will no doubt remain a key player, providing the tools and equipment that manufacturers need to stay competitive in an ever-changing market. Their new automated assembly line is just one more example of their commitment to shaping the future of manufacturing.In conclusion, Machine Industrial's new automated assembly line represents a significant leap forward in the manufacturing industry. With its cutting-edge technology and potential for increased efficiency and profitability, it is sure to make a major impact on the way manufacturers produce their goods. As a company that has always been dedicated to innovation and progress, Machine Industrial is well-positioned to continue leading the way in the industry for years to come.For more information about Machine Industrial and their products and services, visit their website at {}.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.

High Quality PP Woven Sack Printing Machine offers Efficient Printing Solutions

PP Woven Sack Printing Machine: The Game-Changer in Packaging IndustryThe rise of global trade has given birth to the packaging industry. The need to transport goods from one place to another in a secure and efficient way has led to the development of various packaging materials such as corrugated boxes, plastic bags, and woven sacks. Among these materials, woven sacks have gained immense popularity due to their strength and durability.Woven sacks are widely used to package goods such as cement, fertilizer, and animal feed. They are made from polypropylene (PP) material, which is known for its thermal stability, chemical resistance, and moisture resistance. The demand for woven sacks has been increasing due to their eco-friendliness, convenience, and cost-effectiveness.To meet the growing demand for woven sacks, many packaging companies have invested in PP Woven Sack Printing Machines. These machines have revolutionized the manufacturing process of woven sacks by providing high-quality print on them. The PP Woven Sack Printing Machine uses a rotogravure printing process, which involves the use of a cylinder covered in tiny cells to transfer ink onto the woven sack.The PP Woven Sack Printing Machine offers a wide range of benefits to the packaging industry. It provides high-speed printing with a production capacity of up to 120 bags per minute. It also offers customization options, including the ability to print multiple colors, graphics, and logos on the woven sacks. This allows companies to brand their products effectively and distinguish themselves from their competitors.Moreover, the PP Woven Sack Printing Machine saves time and reduces labor costs. It eliminates the need for manual printing, which is a time-consuming and labor-intensive process. The machine also ensures accuracy and consistency in the printing process, resulting in a uniform and professional-looking product.One company that has invested in PP Woven Sack Printing Machines is {} (remove brand name). The company, founded in {}, has established itself as a leading manufacturer and exporter of PP woven sacks. Its state-of-the-art manufacturing facility is equipped with the latest machinery, including PP Woven Sack Printing Machines.The company's PP Woven Sack Printing Machines are capable of producing high-quality prints that are resistant to water, chemicals, and UV radiation. They are also energy-efficient, using less electricity than traditional printing methods. The machines have contributed to the company's success by providing customers with high-quality products that meet their specific requirements.In addition to PP Woven Sack Printing Machines, {} (remove brand name) also offers a wide range of packaging solutions, including woven sacks, laminated bags, and bulk bags. Its products are widely used in the packaging of agricultural, industrial, and construction products.{}(remove brand name) is committed to providing eco-friendly packaging solutions that meet international standards. The company's woven sacks are 100% recyclable and biodegradable, making them an environmentally responsible choice for packaging goods. The company also follows sustainable practices in its manufacturing processes, such as using renewable energy sources and reducing waste.In conclusion, the PP Woven Sack Printing Machine has emerged as a game-changer in the packaging industry, providing high-quality prints on woven sacks and reducing labor costs. Companies like {} (remove brand name) have invested in these machines to meet the growing demand for woven sacks and provide their customers with high-quality products. As the demand for eco-friendly packaging solutions continues to rise, the PP Woven Sack Printing Machine is expected to play a crucial role in the future of the packaging industry.