Efficient and Sustainable Paper Bag Making: Innovations in the Industry

By:Admin

[News Content]:

In today's era of increasing environmental awareness, a sustainable solution for packaging is more crucial than ever before. Enter a leading paper bag maker, a company dedicated to revolutionizing the packaging industry with its eco-friendly approach. By eliminating single-use plastic and creating durable, biodegradable paper bags, this company is setting a new standard for a more sustainable future.

Founded with a vision to reduce plastic waste and promote sustainable alternatives, this paper bag maker has quickly gained recognition for its innovative solutions. With a deep understanding of the detrimental impact of single-use plastic bags on the environment, the company strives to address this issue head-on. By utilizing responsible sourcing of materials and implementing cutting-edge manufacturing techniques, they have developed a range of paper bags that not only meet but exceed industry standards for strength and durability.

One of the key aspects that sets this paper bag maker apart is its commitment to using sustainable materials. They have adopted a comprehensive approach to sourcing, ensuring that all fibers used in their bags come from well-managed forests. By working in partnership with certified suppliers, the company guarantees that its paper bags are made from renewable resources and have a lower carbon footprint compared to traditional plastic bags.

Moreover, the manufacturing process employed by this paper bag maker minimizes the use of harmful chemicals and reduces water consumption. By implementing advanced recycling systems and environmentally friendly practices, they strive to ensure that their production does not contribute to pollution or resource depletion. This commitment to sustainable manufacturing has earned the company accolades within the industry and has positioned them as a leader in eco-friendly packaging solutions.

Another noteworthy feature of this paper bag maker is the versatility of its products. They offer a wide range of bag types, catering to various industries and customer needs. Whether it's a sturdy grocery bag, a stylish gift bag, or a practical takeaway bag, they have a solution for any requirement. By offering customizable options, they allow businesses to showcase their brand while promoting sustainability.

The efforts of this paper bag maker have not gone unnoticed, as many environmentally conscious companies have already adopted their eco-friendly packaging solutions. Their client list includes prominent global brands across sectors such as retail, hospitality, and food services, who believe in supporting a greener future. By choosing these paper bags, these companies not only reduce their environmental impact but also align themselves with the growing demand for sustainable practices among consumers.

Looking ahead, this paper bag maker has ambitious plans for expansion and further innovation. Recognizing the need for continuous improvement, they invest heavily in research and development to create new sustainable alternatives. They aim to push the boundaries of what is possible in the packaging industry and inspire others to follow suit.

In conclusion, this paper bag maker is championing the cause of sustainability in the packaging industry. Through its commitment to responsible sourcing, eco-friendly manufacturing processes, and versatile product offerings, it is reshaping the way businesses package their products. By choosing these paper bags, companies can significantly reduce their environmental footprint while meeting the demands of their customers for greener alternatives. With continued dedication to innovation and expansion, this paper bag maker is leading the way towards a more sustainable future.

Company News & Blog

Woven Sack Bag Cutting Machine for Efficient Bag Manufacturing

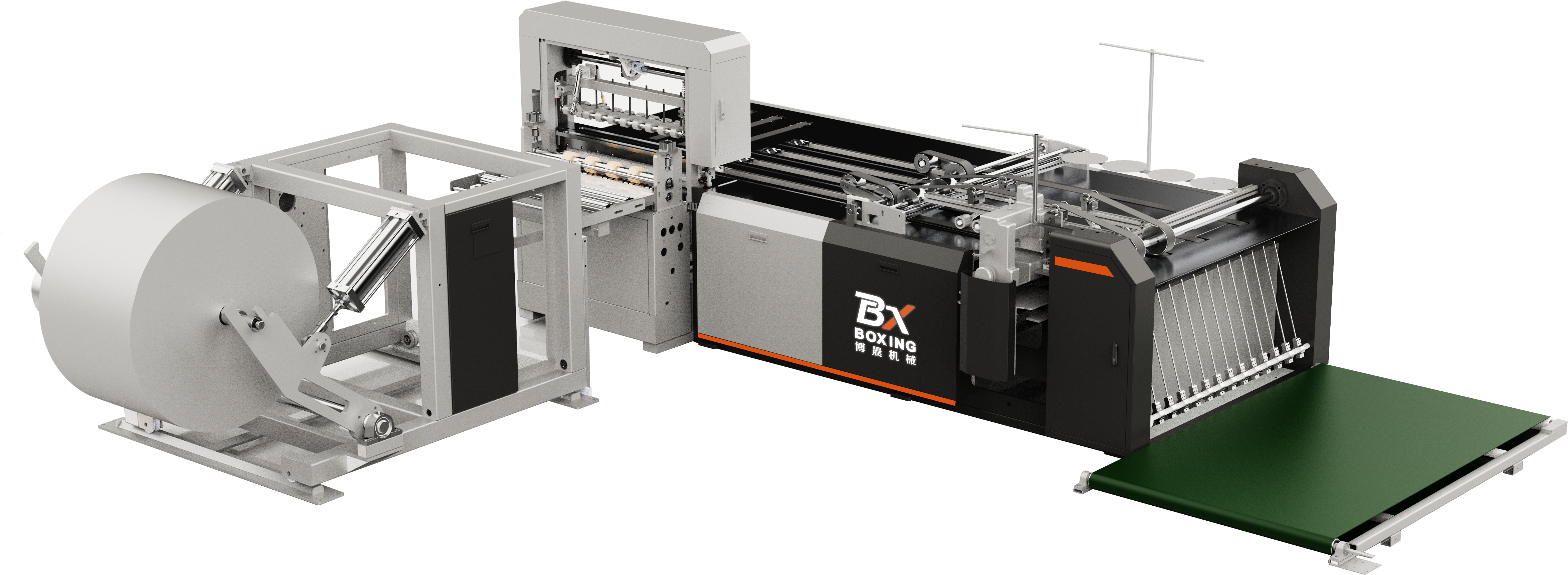

In today's world, the industry has grown and evolved vastly, leading to an increase in demand for efficient and time-saving machinery. The Woven Sack Bag Cutting Machine is one such invention that has revolutionized the manufacturing industry. This machine is used for cutting woven bags into smaller sizes, which is an essential step in the production of bags. They are used for packaging various products such as rice, flour, and fertilizers.The Woven Sack Bag Cutting Machine is gaining popularity due to its ability to save time, reduce labor, and increase productivity. With its automated features, it ensures high accuracy and precision, making it a convenient tool for manufacturers. The quality of the output produced is of premium quality, making it an investment worth making.One notable company producing such cutting machines (need remove brand name) had its inception in 2013 and has since grown in leaps and bounds. The company has over eight years of experience in the industry and is known for delivering cutting-edge technology to its clients. Additionally, the company has a robust team of professionals who design, develop, and manufacture high-quality machinery.Furthermore, the company uses advanced manufacturing practices, and its team has extensive knowledge in designing machinery that provides exceptional quality. This is reflected in the Woven Sack Bag Cutting Machine, which has a high precision rate, and it can handle various materials without damaging them.The machine has a simple user interface that is easy to operate, and its features can be customized to individual requirements. This means that the Woven Sack Bag Cutting Machine is adaptable to various manufacturing processes, allowing the company to cater to the unique needs of its clients.One of the distinguishing features of the machine is its advanced control system, which ensures high accuracy, reducing human error. This not only speeds up production processes, but it also ensures that the output is of superior quality.In addition to the Woven Sack Bag Cutting Machine, the company manufactures a wide range of other machinery essential in the production line. They include cutting machines, printing machines, bag making machines, and non-woven bag making machines. The company's dedication to excellence has seen it earn recognition and awards in the industry.In conclusion, the Woven Sack Bag Cutting Machine is a game-changer in the manufacturing industry. The combination of advanced technology, automation, and precision makes it a must-have investment for bag manufacturers. The company (need remove brand name) stands out as high-quality machinery manufacturers, and its designs are known for their quality and efficiency. With an ever-growing demand for woven bags, this machine is essential in cutting down the costs and reducing production time. The company's commitment to providing exceptional customer service and after-sales support makes it a go-to for businesses of all sizes. Consequently, the Woven Sack Bag Cutting Machine is an investment worth considering for the bag manufacturing industry.

Efficient Cutting, Sewing, and Printing Line Machine for PP Woven Bags

Title: Revolutionary PP Woven Bag Cutting Sewing Printing Line Machine Set to Transform the Packaging IndustryIntroduction:In a significant breakthrough for the packaging industry, a leading manufacturer has recently introduced an innovative PP Woven Bag Cutting Sewing Printing Line Machine. This advanced technology boasts remarkable features that have the potential to revolutionize the way packaging is done across various industries. By automating the bag cutting, sewing, and printing processes, this machine not only enhances productivity but also ensures high-quality packaging solutions.Body:The newly developed PP Woven Bag Cutting Sewing Printing Line Machine is set to deliver unmatched performance in terms of speed, accuracy, and efficiency. Designed with cutting-edge technology and advanced manufacturing capabilities, this machine offers a seamless solution for producing PP woven bags of superior quality.One of the standout features of this machine is its fully automated operation. The machine is equipped with sensors and advanced algorithms that enable precise and consistent cutting, sewing, and printing. This automation significantly reduces human error, enhances production speed, and improves overall efficiency. Furthermore, this technology offers improved safety measures by replacing manual handling, thereby reducing the risk of workplace accidents.The PP woven bags produced by this machine are known for their durability, strength, and resistance to tearing. The machine utilizes high-quality materials that ensure the bags have excellent load-bearing capacity, making them suitable for packaging heavy or bulky items. These bags are widely used in the agricultural, construction, and chemical industries due to their ability to withstand adverse weather conditions and provide ample protection for the contents.Furthermore, the machine's printing capabilities are a game-changer for brands and businesses. With the ability to print high-resolution designs and logos directly onto the bags, it offers a cost-effective and efficient branding solution. This eliminates the need for additional labeling or packaging, reducing costs and increasing brand recognition. The printing process is customizable, allowing businesses to achieve vibrant and intricate designs that stand out on the shelves, attracting consumers’ attention.Incorporating this PP Woven Bag Cutting Sewing Printing Line Machine into production lines provides numerous benefits to businesses. Its high-speed operation enables higher output, allowing manufacturers to meet increased demand without compromising on quality. The machine's flexibility in handling various bag sizes and designs ensures versatility in meeting diverse requirements. Additionally, the durability and aesthetic appeal of the bags contribute to a positive brand image and customer satisfaction.Investing in this cutting-edge technology not only helps businesses become more competitive but also supports sustainable practices. The machine allows for the production of reusable and recyclable bags, which aligns with the global call for reducing plastic waste. By adopting this environmentally conscious approach, businesses can contribute to a greener future while maintaining efficient packaging operations.In conclusion, the introduction of the PP Woven Bag Cutting Sewing Printing Line Machine marks a significant milestone in the packaging industry. Its state-of-the-art technology, fully automated operation, and exceptional bag quality have the potential to transform packaging processes across various sectors. By combining durability, versatility, and branding capabilities, this machine is poised to revolutionize packaging, providing cost-effective and eco-friendly solutions for businesses worldwide.

Revolutionary Suitcase Manufacturing Machine Now Available

Title: Revolutionary Suitcase Manufacturing Machine Poised to Transform the Luggage IndustryIntroduction:In an era where automation and technological advancements are reshaping industries, the luggage manufacturing sector is not far behind. A pioneering suitcase making machine, developed by an innovative company (), promises to revolutionize the production process, providing higher efficiency, improved quality, and reduced costs. This ground-breaking technology is set to make waves in the global luggage market, transforming the way suitcases are manufactured and delivering a positive impact on both businesses and consumers.Background and Company Overview:Operating at the forefront of technological ingenuity, () has emerged as a leading manufacturer of advanced machinery solutions. With a profound understanding of the modern manufacturing landscape, the company has constantly sought to push boundaries and redefine industry norms. Taking this commitment forward, they have recently developed an unparalleled suitcase making machine, set to disrupt the traditional manufacturing practices in the luggage industry.The Suitcase Making Machine:The groundbreaking suitcase making machine developed by () is a marvel of technological innovation. Incorporating state-of-the-art robotics, artificial intelligence, and advanced manufacturing techniques, this advanced machinery is set to transform the way suitcases are produced.Highly efficient and precise, the machine streamlines the entire manufacturing process, minimizing human intervention and significantly reducing the production time. Equipped with advanced sensors, it ensures that each component of the suitcase is assembled flawlessly and adheres to the pre-set quality standards.Moreover, the machine offers unparalleled customizability, enabling businesses to tailor their luggage products according to customer preferences. This customization feature provides an added advantage, allowing companies to cater to niche markets and enhance customer satisfaction.Benefits for Manufacturers:With this innovative technology, luggage manufacturers stand to gain numerous benefits. Firstly, the automated manufacturing process increases productivity manifold, saving valuable time and resources. This increased efficiency translates into cost reduction, enabling companies to offer competitively priced products in the market.Additionally, the machinery eliminates the risk of human errors and inconsistencies, resulting in superior product quality and enhanced brand reputation. The precision offered by the machine ensures that each suitcase is manufactured with utmost precision, durability, and reliability.Furthermore, the customization options offered by the suitcase making machine allow manufacturers to cater to the specific demands of different customer segments, thereby increasing their market reach and revenue streams.Benefits for Consumers:While manufacturers reap the advantages of the suitcase making machine, consumers are not left behind in this technological revolution. The increased efficiency and precision brought about by this cutting-edge machinery translate into improved product quality and durability.Furthermore, the ability of manufacturers to offer customized suitcases ensures that consumers have access to products that perfectly suit their needs and preferences. Whether it is a unique design, specific dimensions, or specialized features, this technology empowers companies to create tailor-made products to cater to diverse customer requirements.Future Outlook and Conclusion:As the luggage industry embraces automation and advanced manufacturing techniques, the suitcase making machine developed by () promises to redefine the standards of suitcase production. With its unparalleled efficiency, precision, and customizability, this technology is set to revolutionize the sector, benefiting both manufacturers and consumers alike.Moving forward, it is imperative for luggage manufacturers to embrace this groundbreaking technology to stay ahead in the competitive market. The future of suitcase manufacturing lies in automated processes, and () is leading the charge in this evolutionary journey.As this industry disruptor gains popularity and wider adoption, it is expected to become the new benchmark in the luggage manufacturing landscape, setting higher standards for quality, efficiency, and customization in the years to come.

New Innovative Print Machine Boosts Efficiency and Productivity in the Market

Title: Advanced Print Machine Revolutionizes CI Industry with Cutting-Edge TechnologyIntroductionIn a significant breakthrough for the continuous inkjet (CI) printing industry, a leading technology company has unveiled its latest innovation, an advanced CI print machine. This groundbreaking new device, with its state-of-the-art features and cutting-edge technology, promises to revolutionize the printing and packaging sector. By offering improved efficiency, environmental sustainability, and enhanced print quality, this revolutionary CI print machine sets a new standard in the industry.Deep DiveThe introduction of this game-changing CI print machine comes as a result of extensive research and development efforts by the company's team of highly skilled engineers. By successfully integrating advanced technologies and innovative features, this print machine is tailored to meet the diverse needs of the printing industry.With an emphasis on sustainability, the new CI print machine boasts substantial improvements in terms of energy consumption and resource efficiency. By implementing intelligent power management systems, the machine achieves a significant reduction in power consumption, resulting in lower operating costs for businesses while minimizing its environmental impact.Furthermore, the print machine utilizes a cutting-edge ink formulation that maximizes ink usage, reducing ink wastage and promoting sustainability in the printing process. The intelligently designed ink system ensures precise ink control, enabling high-quality prints while minimizing ink consumption.Another groundbreaking feature of this CI print machine is its enhanced print speed. With its advanced print head technology, the machine achieves uninterrupted high-speed printing, leading to improved productivity and reduced production timelines. This allows businesses to meet tight deadlines and high-volume demands, giving them a competitive edge in the market.Moreover, the CI print machine is equipped with intelligent sensors that detect and correct printing errors in real-time, ensuring consistent print quality throughout the production process. This technology reduces the need for reprints, thus minimizing cost and material waste. The resulting print quality surpasses the industry norm, providing businesses with impressive visual appeal and accuracy in their printed materials.The user-friendly interface of the CI print machine further enhances its appeal to businesses. With its intuitive controls and simplified operation, it offers effortless set-up and printing processes. The built-in troubleshooting system provides easy diagnosis and resolution of any technical issues, reducing downtime and maximizing efficiency.In addition to its innovative features, the CI print machine is designed to seamlessly integrate into existing production lines, making it a versatile solution for businesses of all sizes. This compatibility ensures a smooth transition to the advanced print technology without requiring a complete overhaul of the existing infrastructure.The CI print machine is set to create a significant impact in the packaging industry, particularly in applications such as food and beverage packaging, pharmaceutical labeling, and product branding. Its ability to deliver consistently high-quality prints, combined with its environmentally friendly features, makes it an ideal choice for companies aiming to enhance brand value and consumer satisfaction.ConclusionWith its advanced technology and groundbreaking features, the new CI print machine is poised to revolutionize the printing and packaging industry. The integration of sustainability, increased efficiency, and superior print quality sets a new industry standard. Businesses can now benefit from reduced costs, enhanced productivity, and improved environmental sustainability, positioning themselves at the forefront of their respective markets. The launch of this groundbreaking CI print machine undoubtedly proves the company's commitment to technological innovation and its dedication to providing cutting-edge solutions to meet evolving industry needs.

Efficient and Sustainable Paper Bag Making: Innovations in the Industry

[News Title]: Sustainable Paper Bag Maker Revolutionizes Packaging Industry[News Content]:In today's era of increasing environmental awareness, a sustainable solution for packaging is more crucial than ever before. Enter a leading paper bag maker, a company dedicated to revolutionizing the packaging industry with its eco-friendly approach. By eliminating single-use plastic and creating durable, biodegradable paper bags, this company is setting a new standard for a more sustainable future.Founded with a vision to reduce plastic waste and promote sustainable alternatives, this paper bag maker has quickly gained recognition for its innovative solutions. With a deep understanding of the detrimental impact of single-use plastic bags on the environment, the company strives to address this issue head-on. By utilizing responsible sourcing of materials and implementing cutting-edge manufacturing techniques, they have developed a range of paper bags that not only meet but exceed industry standards for strength and durability.One of the key aspects that sets this paper bag maker apart is its commitment to using sustainable materials. They have adopted a comprehensive approach to sourcing, ensuring that all fibers used in their bags come from well-managed forests. By working in partnership with certified suppliers, the company guarantees that its paper bags are made from renewable resources and have a lower carbon footprint compared to traditional plastic bags.Moreover, the manufacturing process employed by this paper bag maker minimizes the use of harmful chemicals and reduces water consumption. By implementing advanced recycling systems and environmentally friendly practices, they strive to ensure that their production does not contribute to pollution or resource depletion. This commitment to sustainable manufacturing has earned the company accolades within the industry and has positioned them as a leader in eco-friendly packaging solutions.Another noteworthy feature of this paper bag maker is the versatility of its products. They offer a wide range of bag types, catering to various industries and customer needs. Whether it's a sturdy grocery bag, a stylish gift bag, or a practical takeaway bag, they have a solution for any requirement. By offering customizable options, they allow businesses to showcase their brand while promoting sustainability.The efforts of this paper bag maker have not gone unnoticed, as many environmentally conscious companies have already adopted their eco-friendly packaging solutions. Their client list includes prominent global brands across sectors such as retail, hospitality, and food services, who believe in supporting a greener future. By choosing these paper bags, these companies not only reduce their environmental impact but also align themselves with the growing demand for sustainable practices among consumers.Looking ahead, this paper bag maker has ambitious plans for expansion and further innovation. Recognizing the need for continuous improvement, they invest heavily in research and development to create new sustainable alternatives. They aim to push the boundaries of what is possible in the packaging industry and inspire others to follow suit.In conclusion, this paper bag maker is championing the cause of sustainability in the packaging industry. Through its commitment to responsible sourcing, eco-friendly manufacturing processes, and versatile product offerings, it is reshaping the way businesses package their products. By choosing these paper bags, companies can significantly reduce their environmental footprint while meeting the demands of their customers for greener alternatives. With continued dedication to innovation and expansion, this paper bag maker is leading the way towards a more sustainable future.

Enhancing Efficiency: Discover the Benefits of Industrial Packing Machines

Industrial Packing Machine Launches Advanced Packaging Solutions Industrial Packing Machine, a leading provider of innovative packaging machinery, has unveiled its latest range of advanced packaging solutions. The company, with decades of expertise in the industry, aims to revolutionize the packaging process for businesses across various sectors.As a pioneer in the field, Industrial Packing Machine has always remained committed to delivering top-quality and reliable packaging solutions. The company's team of experienced engineers and designers strive to develop cutting-edge systems that streamline the packaging process while ensuring maximum efficiency and durability.The newly launched range of packing machines incorporates state-of-the-art technology and features designed to meet the evolving needs of diverse industries. These advanced solutions offer businesses improved speed, accuracy, and reliability, ultimately translating into enhanced productivity and profitability.One of the highlights of the new range is the fully automated packing system. This intelligent packaging solution minimizes human intervention, reducing the risk of errors and ensuring consistent and precise packaging. Equipped with smart sensors and high-speed motors, the automated system can handle a wide variety of products with different shapes and sizes. Additionally, it enables the integration and synchronization of multiple machines, streamlining the packaging line for seamless production.Industrial Packing Machine's commitment to customization is evident in its launch of customized packing solutions. The company understands that each business has unique packaging requirements, and thus offers tailored solutions to cater to those needs. From custom-shaped packaging to specific labeling and marking requirements, Industrial Packing Machine's engineers work closely with clients to design and develop solutions that address their individual packaging challenges.To further enhance the efficiency and performance of the packaging process, Industrial Packing Machine has introduced its innovative quality control technologies. The integrated inspection systems ensure that each package meets the desired standards and specifications. These automated quality control systems detect and eliminate any defects or inconsistencies, eliminating the possibility of faulty products reaching the market. This feature plays a crucial role in maintaining brand reputation and customer satisfaction.Environmental considerations have become increasingly important in the packaging industry in recent years. In response to this emerging trend, Industrial Packing Machine has implemented eco-friendly features in its new range. The machines are designed to minimize material wastage and optimize energy consumption, contributing to a more sustainable packaging process. By investing in these advanced solutions, businesses can align their operations with environmental responsibility and demonstrate their commitment to sustainability.Industrial Packing Machine's dedication to customer satisfaction extends beyond the development of cutting-edge machinery. The company provides comprehensive after-sales support to ensure the optimal performance and longevity of its products. Skilled technicians offer installation, training, and maintenance services, ensuring that clients can operate their packing machines efficiently and effectively.With its latest range of advanced packaging solutions, Industrial Packing Machine aims to set a new benchmark in the industry. The company's commitment to innovation, customization, and sustainability positions it as an ideal partner for businesses looking to optimize their packaging processes. As the market continues to evolve, Industrial Packing Machine remains at the forefront by consistently delivering advanced and reliable solutions that meet the diverse needs of its clients.

Efficient and Cost-Effective Bag Cutting Machines for Various Industries

PP Bag Cutting Machine Streamlines Manufacturing Process for Packaging IndustryThe packaging industry is one of the largest and most diverse sectors of the manufacturing industry, with a wide range of products and materials used to create custom packaging solutions for businesses across the globe. In order to keep up with the growing demand for high-quality packaging materials, manufacturers need to utilize the latest technologies and equipment to streamline their processes and improve efficiencies.One such technology is the PP bag cutting machine which is now being widely adopted by packaging companies around the world. This advanced machine has revolutionized the way packaging materials are produced, making it faster, easier, and more cost-effective for manufacturers to create custom packaging solutions for their clients.Combining advanced features with a user-friendly design, these machines are able to cut and shape polypropylene bags with extreme precision, producing high-quality products that meet the demanding standards of the packaging industry. These machines not only reduce the time and effort required to create packaging materials, but they also help to reduce the amount of waste generated during the manufacturing process.One of the leading manufacturers of PP bag cutting machines is a company based in China. Boasting over 20 years of experience in the packaging industry, they are known for their innovative solutions and quality products. Their PP bag cutting machines are designed to handle a wide range of materials and can be customized to meet the specific needs of each client.The company's PP bag cutting machine features a state-of-the-art cutting system that allows for precise and accurate cuts, resulting in a high-quality finish. The machine is also equipped with a variable speed motor, which allows for greater control over the cutting process, as well as a touch screen control panel which makes it easy to adjust settings and operate the machine.One of the key benefits of the company's PP bag cutting machine is its versatility. It can be used to create a wide range of products, from simple bags and pouches to more complex shapes and designs. It can also be used to cut a variety of materials, including woven and non-woven fabrics, as well as films and laminates.The machine is also designed to be easy to use, with a straightforward design that minimizes the time and effort required for set up and operation. It also comes with a range of safety features, including an emergency stop button and overload protection, to ensure the safety of operators and equipment.The company's commitment to quality and innovation has earned them a reputation as a leader in the packaging industry. Their PP bag cutting machines are used by businesses of all sizes, from small startups to multinational corporations, in industries ranging from food and beverage to industrial and pharmaceutical.In addition to their PP bag cutting machines, the company also offers a range of other cutting and welding solutions for the packaging industry. These include ultrasonic cutting machines, high frequency welding machines, and hot air welding machines, all designed to streamline the manufacturing process and improve efficiencies.As the demand for high-quality packaging materials continues to grow, companies in the packaging industry need to invest in the latest technologies and equipment to stay ahead of the competition. The PP bag cutting machine is one such technology, offering a range of benefits that can help businesses improve their processes, reduce waste, and increase profitability.If you're a manufacturer in the packaging industry looking for innovative solutions to improve your efficiency and productivity, be sure to check out the company's range of cutting and welding machines, including their state-of-the-art PP bag cutting machine. With their commitment to quality and customer service, they can help you stay ahead of the curve and achieve your goals in a competitive market.

Revolutionary Technology for Accurately Inserting Items into Containers

Title: Revolutionary Inserting Machine Revolutionizes Automation in the Packaging IndustryIntroduction:In a groundbreaking development that is set to transform the packaging industry, a leading company has unveiled its latest innovation – an Inserting Machine that promises to revolutionize automation and enhance operational efficiency. By seamlessly integrating cutting-edge technology with intelligent software systems, this state-of-the-art solution aims to streamline the packaging process, boost productivity, and reduce costs. With its potential to bring about notable advancements in the packaging industry, services offered by this Inserting Machine can redefine automated packaging systems as we know them.1. Enhanced Efficiency Spurs Productivity GainThe Inserting Machine leverages advanced robotics and artificial intelligence to optimize the packaging process, offering higher levels of efficiency than ever before. The intelligent automation system efficiently inserts various materials into packages, significantly reducing manual labor and human error. By eliminating the need for manual handling of materials, the machine substantially reduces the time required for the packaging process, paving the way for higher productivity levels and increased output.2. Improved Accuracy and ReliabilityWith its cutting-edge technology, the Inserting Machine guarantees superior accuracy and reliability in every packaging operation. Equipped with advanced sensors and precise measurement systems, this automated solution ensures that materials are inserted with unmatched precision, minimizing errors and product defects. By upholding a high degree of quality control, companies can significantly reduce waste and optimize their production line, ultimately leading to improved customer satisfaction.3. Scalability and AdaptabilityThe flexible design of the Inserting Machine allows for seamless integration with existing packaging systems. Whether utilized as a standalone unit or integrated into an assembly line, this solution offers unparalleled scalability and adaptability. Its modular construction enables easy customization and expansion, catering to the varying needs of different industries and product lines. This adaptability eliminates the need for extensive system overhauls and ensures businesses can respond swiftly to changing market demands.4. Cutting-edge Technology Drives InnovationThe Inserting Machine showcases the transformative power of cutting-edge technology in the packaging industry. Its innovative features include computer vision technology, machine learning algorithms, and advanced robotics. Computer vision allows the machine to accurately identify and locate the insertion points, while machine learning algorithms enable continuous improvement of productivity and quality. Advanced robotics ensure swift and precise movements, ensuring optimal efficiency in every operation. By harnessing these technologies, businesses can stay at the forefront of the packaging industry.5. Cost Reduction and Increased ROIThe implementation of the Inserting Machine can translate into significant cost reduction for businesses. By eliminating the need for manual labor, companies can reduce workforce requirements and alleviate labor costs. Moreover, the reduction in errors and waste saves valuable resources, further contributing to cost savings. Over time, businesses can witness a considerable return on investment through increased productivity, improved efficiency, and minimized expenses.Conclusion:The introduction of the Inserting Machine represents a groundbreaking advancement for the packaging industry. Combining state-of-the-art technology, precision engineering, and intelligent software systems, this innovative solution has the potential to reshape the automation landscape. As businesses increasingly seek to enhance operational efficiency, reduce human error, and increase productivity, the Inserting Machine emerges as a transformative force that ensures superior accuracy, reliability, and cost savings. With its scalability and adaptability, this automated packaging solution promises to pave the way for a new era of efficiency and profitability in the industry.

Introduction to the Latest Trends and Uses of Pp Woven Fabric in Various Industries

[Company Introduction] [Remove Brand Name] is a leading manufacturer and supplier of high-quality PP woven fabric solutions. With years of experience and a commitment to innovation, we have been providing reliable and sustainable packaging solutions to various industries worldwide. Our state-of-the-art manufacturing facilities, strict quality control measures, and a talented team of professionals have earned us a reputable position in the market.Our diverse range of PP woven fabric products caters to the packaging needs of industries such as agriculture, building and construction, chemicals, food and beverages, and many more. We understand the importance of durable and efficient packaging, and thus our fabrics are designed to withstand various environmental and transportation conditions.Our PP woven fabric is made from the highest quality polypropylene materials, ensuring excellent strength, tear resistance, and durability. The fabric is woven using advanced machinery, under strict quality control processes, resulting in consistent and reliable performance. We offer a wide range of fabric weights and sizes to meet the specific requirements of our customers.One of the key advantages of our PP woven fabric is its versatility. It can be customized with various treatments and finishes, including UV stabilization, anti-skid properties, and fire retardancy, to enhance its performance and suitability for specific applications. Additionally, our fabric is available in different colors, allowing for easy identification and branding opportunities.Our commitment to sustainability is at the core of our operations. We strive to minimize the environmental impact of our products and processes by implementing recycling programs, reducing waste generation, and optimizing energy consumption. Our reusable PP woven fabric solutions contribute to reducing single-use plastic waste and promoting a circular economy.[Remove Brand Name]'s commitment to customer satisfaction is reflected in our reliable and efficient customer service. We work closely with our clients to understand their packaging requirements and provide tailored solutions that meet their needs. Our dedicated team of sales professionals, technicians, and engineers ensure prompt delivery, installation, and support throughout the entire product lifecycle.In line with our vision to constantly innovate and improve, we invest in research and development to develop new and advanced PP woven fabric solutions. We collaborate with industry experts, universities, and research institutions to stay at the forefront of technological advancements and deliver cutting-edge products to our customers.[Remove Brand Name] has a global presence and exports its products to numerous countries. Our strong distribution network ensures timely delivery of our products to our clients, regardless of their location. Our commitment to quality, reliability, and customer satisfaction has earned us long-term partnerships with leading companies in various industries.In conclusion, [Remove Brand Name] is a trusted manufacturer and supplier of high-quality PP woven fabric solutions. With a focus on innovation, sustainability, and customer satisfaction, we strive to meet the diverse packaging needs of industries worldwide. Our commitment to excellence and continuous improvement sets us apart in the market, making us the preferred choice for reliable packaging solutions.

Efficient Bag Making Equipment: A Must-Have for Streamlined Production

Title: Revolutionizing Bag Production: Innovative Bag Making Equipment Revolutionizes IndustryIntroduction:In a bid to redefine bag production and meet the changing demands of consumers, a leading manufacturer of bag making equipment has introduced a groundbreaking solution that promises to revolutionize the industry. This cutting-edge technology, developed by a highly skilled team of engineers at the company in question, is poised to transform bag manufacturing processes, enabling businesses to enhance productivity and produce higher-quality bags at an unprecedented scale. Let's delve into the details of this groundbreaking innovation and its potential impact on the bag manufacturing sector.I. Background:Bag making has long been a crucial aspect of many industries, catering to the packaging requirements of various sectors such as retail, food and beverage, agriculture, and more. Traditional bag making equipment often faced challenges related to speed, precision, and flexibility, limiting manufacturers' abilities to keep up with market demands efficiently.Realizing this market need, the engineers at Bag Making Equipment have dedicated years of research and development efforts to create a game-changing solution that addresses these limitations head-on. The new equipment aims to streamline bag production, reducing costs and increasing efficiency for manufacturers across the globe.II. Technological Advancements:The bag making equipment developed by Bag Making Equipment showcases a host of technological advancements aimed at delivering an exceptional bag manufacturing experience. Several notable features set this technology apart from traditional systems, including:1. Precision Engineering: Leveraging cutting-edge design techniques, the equipment has been engineered to ensure precision in every step of the bag-making process. From cutting and sealing to printing and finishing, this equipment guarantees high-quality results, free from defects or imperfections.2. Enhanced Speed and Efficiency: Through the integration of advanced automation systems, the bag making equipment significantly enhances the speed and efficiency of production lines. This allows manufacturers to meet ever-increasing customer demands while reducing production time and costs.3. Versatility and Flexibility: The new equipment allows manufacturers to produce a wide range of bag types and sizes on a single production line. From simple grocery bags to complex packaging solutions, this versatility provides immense flexibility and caters to the diverse needs of various industries.4. Intelligent Control Systems: The state-of-the-art control systems embedded within the equipment allow operators to monitor and adjust critical parameters in real-time. This ensures consistent quality control and minimizes the risk of errors or downtime.III. Potential Impact:The introduction of this advanced bag making equipment could have a transformative impact on the bag manufacturing industry. The benefits it offers include:1. Increased Production Capacity: By optimizing production processes, reducing downtime, and enhancing speed, manufacturers can significantly increase their overall production capacity. This allows them to take on larger orders, meet customer demands promptly, and expand their market reach.2. Enhanced Quality Control: The high precision and intelligent control systems of the equipment facilitate superior quality control throughout the bag-making process, minimizing defects and ensuring consistency. This can help businesses establish a reputation for delivering top-quality bags, boosting customer satisfaction and loyalty.3. Cost Reduction: The efficiency gains achieved through the use of this equipment lead to cost reductions in labor, raw materials, and energy consumption, improving the overall profitability of bag manufacturers. This cost-effectiveness enhances their competitive edge in the market and supports business growth.IV. Conclusion:Bag Making Equipment's cutting-edge bag making technology is poised to redefine bag production processes globally, empowering manufacturers to meet the rapidly evolving demands of customers. By blending precision engineering, automation, and versatility, this equipment promises superior bag quality, increased production capacity, and reduced costs. As bag manufacturers equip themselves with this innovative solution, we can expect the sector to witness substantial growth and opportunities for both businesses and consumers alike.