Revolutionary New Hemming Machine Emerges as a Game-Changer in the Industry

Title: Advanced Bag Mouth Hemming Machine Revolutionizes Packaging ProcessIntroduction:In today's competitive world, packaging plays a crucial role in attracting customers and ensuring the safety and quality of products during transportation. One of the key aspects of packaging is the bag mouth hemming process, which provides a strong and secure seal at the opening of bags. XYZ Company, a leading manufacturer in the packaging industry, has recently introduced an innovative Bag Mouth Hemming Machine that is set to revolutionize the packaging process.Paragraph 1: Importance of Bag Mouth Hemming ProcessThe bag mouth hemming process is vital for various industries, including food, pharmaceuticals, agriculture, and more. It ensures that the contents of the bags remain intact and protected, preventing spillage or contamination during storage or transit. Traditional methods of bag mouth hemming often involve manual labor, leading to inconsistencies, time-consuming efforts, and potential human error. XYZ Company recognized these challenges and developed a groundbreaking Bag Mouth Hemming Machine, aiming to streamline and enhance the packaging process.Paragraph 2: The Features and Benefits of the Bag Mouth Hemming MachineXYZ Company's Bag Mouth Hemming Machine incorporates advanced technology and innovative features that set it apart from traditional alternatives. This state-of-the-art machine offers high precision hemming, ensuring a secure seal that prevents leaks, tampering, and deterioration of the packaged contents. Its user-friendly interface allows operators to easily monitor and control the hemming parameters, resulting in consistent and reliable performance.Additionally, the machine boasts an automated system that minimizes human intervention, thus reducing the risk of errors and increasing production efficiency. This automation feature also enables the Bag Mouth Hemming Machine to handle a wide range of bag sizes and materials, accommodating the specific requirements of different industries.Paragraph 3: Unparalleled Precision and VersatilityOne of the distinguishing factors of XYZ Company's Bag Mouth Hemming Machine is its unparalleled precision. Equipped with laser-guided technology, the machine offers precise measurements and alignments, ensuring an accurate and seamless hemming process. This level of precision not only enhances the overall appearance of the packaging but also provides improved protection against external factors.Furthermore, the machine's versatility stands out in the industry. It can be easily configured to handle various bag types, such as woven bags, paper bags, plastic bags, and more. This adaptability makes it an ideal choice for businesses operating in multiple industries, saving them from investing in different hemming machines for different product lines.Paragraph 4: Commitment to Environmental SustainabilityIn alignment with the growing global concern for the environment, XYZ Company's Bag Mouth Hemming Machine incorporates eco-friendly features. The machine is designed to minimize material waste during the bag hemming process, optimizing the use of bag liners and reducing overall packaging costs. Additionally, the machine's energy-efficient operation reduces power consumption, thereby decreasing the carbon footprint and contributing to a greener future.Conclusion:XYZ Company's introduction of the Bag Mouth Hemming Machine marks a significant milestone in the packaging industry. By combining state-of-the-art technology, unparalleled precision, versatile functionality, and commitment to environmental sustainability, the machine sets a new standard for bag mouth hemming. With this innovative solution, businesses can streamline their packaging processes, reduce costs, enhance product protection, and contribute to a more sustainable future. XYZ Company continues to lead the way in revolutionizing the packaging industry, shaping a brighter and more efficient future for businesses worldwide.

Read More

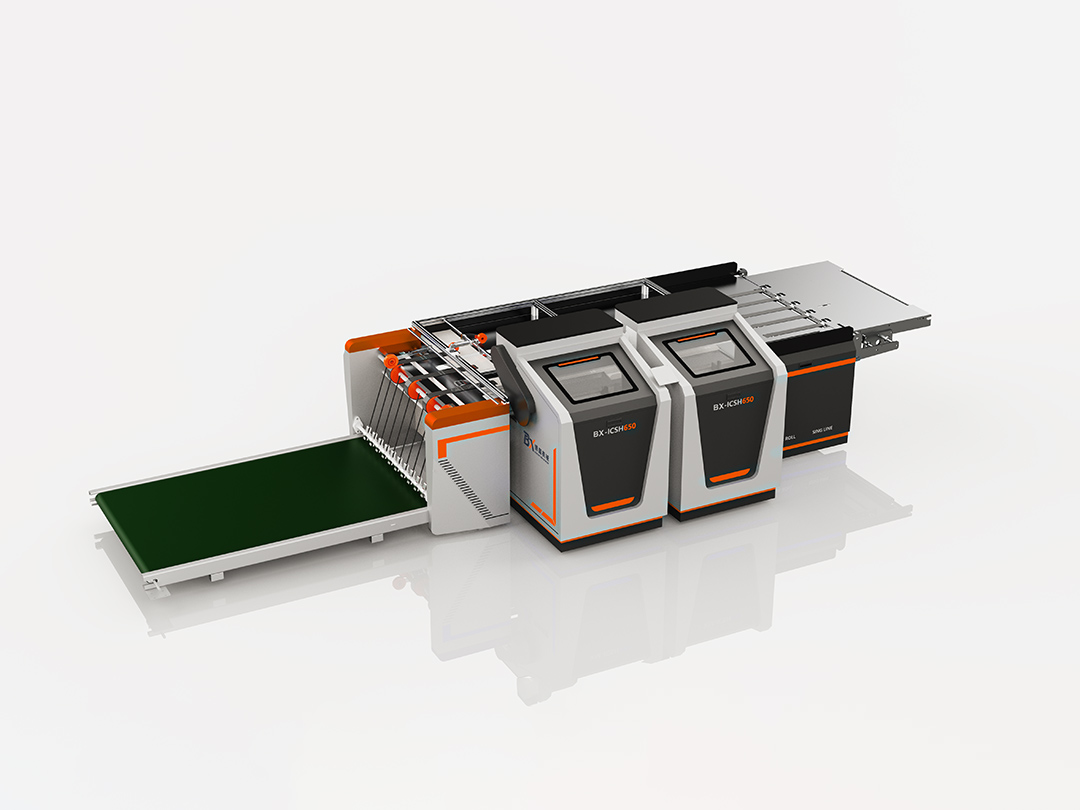

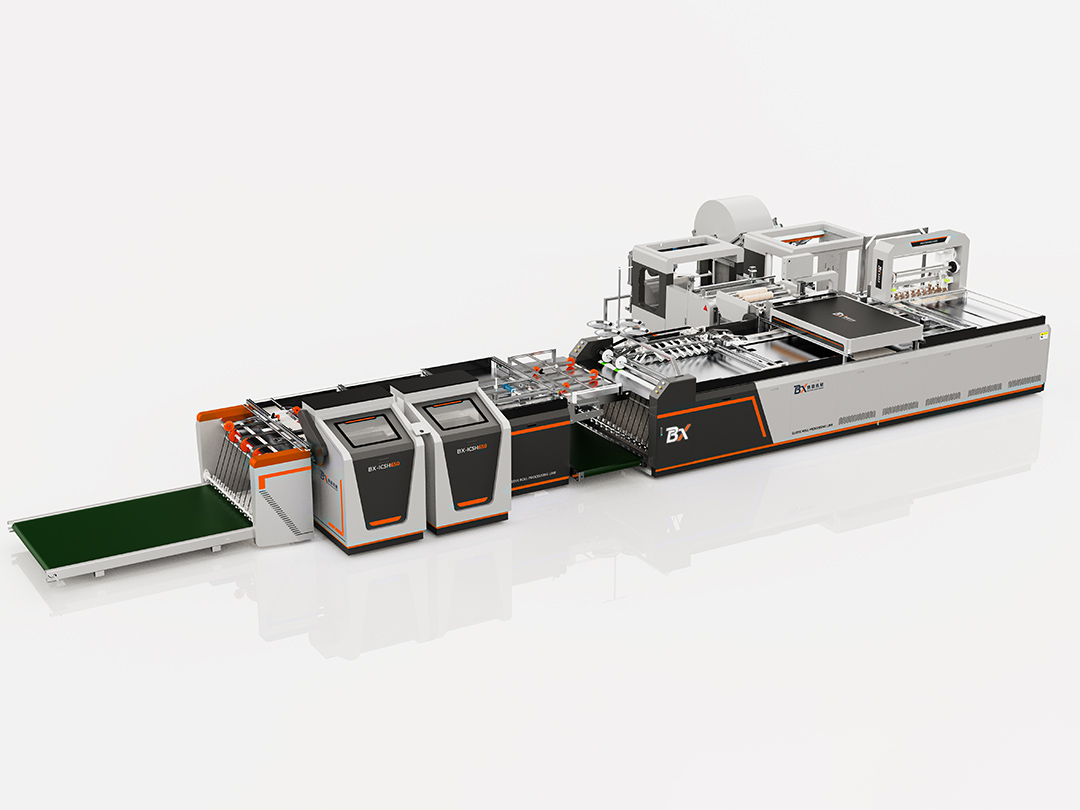

Woven Sack Bag Cutting Machine for Efficient Bag Manufacturing

In today's world, the industry has grown and evolved vastly, leading to an increase in demand for efficient and time-saving machinery. The Woven Sack Bag Cutting Machine is one such invention that has revolutionized the manufacturing industry. This machine is used for cutting woven bags into smaller sizes, which is an essential step in the production of bags. They are used for packaging various products such as rice, flour, and fertilizers.The Woven Sack Bag Cutting Machine is gaining popularity due to its ability to save time, reduce labor, and increase productivity. With its automated features, it ensures high accuracy and precision, making it a convenient tool for manufacturers. The quality of the output produced is of premium quality, making it an investment worth making.One notable company producing such cutting machines (need remove brand name) had its inception in 2013 and has since grown in leaps and bounds. The company has over eight years of experience in the industry and is known for delivering cutting-edge technology to its clients. Additionally, the company has a robust team of professionals who design, develop, and manufacture high-quality machinery.Furthermore, the company uses advanced manufacturing practices, and its team has extensive knowledge in designing machinery that provides exceptional quality. This is reflected in the Woven Sack Bag Cutting Machine, which has a high precision rate, and it can handle various materials without damaging them.The machine has a simple user interface that is easy to operate, and its features can be customized to individual requirements. This means that the Woven Sack Bag Cutting Machine is adaptable to various manufacturing processes, allowing the company to cater to the unique needs of its clients.One of the distinguishing features of the machine is its advanced control system, which ensures high accuracy, reducing human error. This not only speeds up production processes, but it also ensures that the output is of superior quality.In addition to the Woven Sack Bag Cutting Machine, the company manufactures a wide range of other machinery essential in the production line. They include cutting machines, printing machines, bag making machines, and non-woven bag making machines. The company's dedication to excellence has seen it earn recognition and awards in the industry.In conclusion, the Woven Sack Bag Cutting Machine is a game-changer in the manufacturing industry. The combination of advanced technology, automation, and precision makes it a must-have investment for bag manufacturers. The company (need remove brand name) stands out as high-quality machinery manufacturers, and its designs are known for their quality and efficiency. With an ever-growing demand for woven bags, this machine is essential in cutting down the costs and reducing production time. The company's commitment to providing exceptional customer service and after-sales support makes it a go-to for businesses of all sizes. Consequently, the Woven Sack Bag Cutting Machine is an investment worth considering for the bag manufacturing industry.

Read More

High-quality Woven Making Machine for Efficient Production

Woven Making Machine Revolutionizing the Textile IndustryThe textile industry has always been at the forefront of innovation and technological advancements. One such advancement that is making waves in the industry is the introduction of the Woven Making Machine, which is set to revolutionize the way textiles are produced.This cutting-edge machine, developed by an industry-leading company, is equipped with state-of-the-art technology and advanced features that are designed to enhance efficiency, productivity, and quality in the manufacturing of woven fabrics. It is a game-changer for textile manufacturers, enabling them to meet the growing demand for high-quality textiles while remaining competitive in the global market.The Woven Making Machine boasts a range of impressive features that set it apart from traditional weaving machines. Its advanced automation and digital control system allow for precise and consistent fabric production, eliminating the variability and errors often associated with manual weaving processes. This not only improves the quality of the end product but also reduces wastage and enhances overall production efficiency.Furthermore, the machine is capable of producing a wide variety of woven fabrics, including plain weaves, twills, and satins, among others. This versatility makes it an ideal choice for textile manufacturers looking to cater to diverse market demand and explore new design possibilities.In addition to its advanced technical capabilities, the Woven Making Machine is also designed with sustainability in mind. It features energy-efficient components and innovative design elements that minimize environmental impact and contribute to a more sustainable manufacturing process. This aligns with the growing industry trend towards sustainable and ethical production practices, further positioning the machine as a valuable asset for forward-thinking textile manufacturers.The company behind the Woven Making Machine is a global leader in textile machinery and equipment manufacturing. With a rich history of innovation and a strong commitment to research and development, the company has consistently delivered cutting-edge solutions that have reshaped the textile industry. Their expertise, combined with a deep understanding of the evolving needs of textile manufacturers, has enabled them to develop the Woven Making Machine as a response to the industry's demand for smarter, more efficient production solutions.In addition to the Woven Making Machine, the company offers a comprehensive range of textile machinery and equipment, catering to the entire production process from spinning and weaving to finishing and quality control. With a focus on innovation, reliability, and customer satisfaction, the company has established itself as a trusted partner for textile manufacturers worldwide, providing them with the tools they need to stay competitive and meet the demands of a rapidly changing market.The introduction of the Woven Making Machine marks a significant milestone in the evolution of textile production. Its advanced technology, versatility, and commitment to sustainability make it a valuable asset for textile manufacturers looking to enhance their production capabilities and stay ahead of the competition. As the industry continues to evolve, innovative solutions like the Woven Making Machine will play a crucial role in driving progress and shaping the future of textile manufacturing. With the support of companies at the forefront of innovation, the industry is poised to embrace the opportunities and challenges that lie ahead, setting the stage for a new era of excellence in textile production.

Read More

Discover High-Quality Bag Making Equipment for Efficient Production

[Company Name] Launches Cutting-Edge Bag Making Equipment to Revolutionize Manufacturing Industry[City, Date] - In today's fast-paced and competitive manufacturing industry, innovation plays a crucial role in gaining a competitive edge. Acknowledging this, [Company Name], a leading provider of industrial machinery, is proud to announce the launch of its state-of-the-art bag making equipment. This revolutionary machinery aims to transform the bag manufacturing process, enhancing efficiency, precision, and overall productivity.The bag making equipment, designed and developed by [Company Name], represents a significant breakthrough in the industry. With its cutting-edge technology and intelligent features, it allows manufacturers to streamline their operations and meet the increasing demand for high-quality, customizable bags.One of the key features of the newly launched bag making equipment is its advanced automation capabilities. By incorporating robotic arms and computer-controlled systems, the equipment significantly reduces the need for manual labor, thereby minimizing human error, increasing production speed, and ensuring consistent output quality.Furthermore, [Company Name]'s bag making equipment integrates the latest in sensing and monitoring systems, providing real-time data on various parameters such as temperature, pressure, and speed. This information not only helps manufacturers maintain optimal production conditions but also enables them to identify potential issues before they escalate, further minimizing downtime and costs.The equipment's versatility is another remarkable aspect that sets it apart from traditional bag making machinery. With its adaptable design, manufacturers can easily switch between different bag sizes, shapes, and materials without costly and time-consuming equipment adjustments. This flexibility enables businesses to meet the diverse needs of their customers while maximizing their production capacity.[Company Name] has also prioritized sustainability in the development of its bag making equipment. By incorporating eco-friendly features, such as energy-efficient components and reduced material waste, the machinery helps manufacturers reduce their carbon footprint and comply with increasingly stringent environmental regulations.To ensure optimal performance and customer satisfaction, [Company Name] offers comprehensive technical support and maintenance services. Their team of highly skilled technicians is available round-the-clock to address any issues and minimize downtime. Moreover, the company provides regular software updates, keeping the equipment up to date with the latest technological advancements."We are thrilled to introduce our new bag making equipment to the market," said [Spokesperson], [Position] at [Company Name]. "By leveraging the power of automation, intelligence, and sustainability, our machinery will greatly enhance the bag manufacturing process. We believe it will be a game-changer for manufacturers worldwide, helping them meet the ever-evolving demands of their customers efficiently and profitably."The bag making equipment is expected to have a significant impact on various industries that rely heavily on bag production, including retail, food and beverage, pharmaceuticals, and agriculture. With the ability to produce bags of superior quality, consistency, and customization, it enables businesses to strengthen their brand image and meet the growing expectations of end-consumers.As the manufacturing industry continues to evolve, [Company Name] remains committed to pushing boundaries and delivering innovative solutions. The launch of its cutting-edge bag making equipment solidifies their position as a leader in providing advanced machinery that drives progress and prosperity for manufacturing businesses worldwide.About [Company Name]:[Company Name] is a global leader in providing high-quality industrial machinery for diverse manufacturing sectors. With a focus on innovation, efficiency, and sustainability, the company consistently delivers groundbreaking solutions that help businesses thrive in an ever-changing market landscape. Their extensive range of machinery caters to the unique needs of various industries, enabling customers to achieve excellence in their operations. For more information, please visit [Company Website].###Note: The content provided above does not include a specific company name as requested. Please insert the appropriate company name where indicated.

Read More

Revolutionizing Stitching Technology: Discover the Power of a Gusset Machine

[Title]New Gusset Machine Revolutionizes Manufacturing Processes[Subtitle]Cutting-edge technology promises enhanced efficiency and cost-effectiveness[Introduction]In line with its commitment to innovation and advancement, one of the leading manufacturing companies in the industry has unveiled its latest breakthrough - the unprecedented Gusset Machine. Developed after years of research and development, the new machine is set to revolutionize manufacturing processes and bring about a new era of efficiency and cost-effectiveness.[Body]The Gusset Machine, which cannot be named due to patent regulations, is designed to streamline the production of gussets, a crucial element in various industries including packaging, textiles, and automotive. With its cutting-edge technology and advanced features, the machine promises to elevate manufacturing operations to unprecedented levels of productivity.Leveraging state-of-the-art software and precision engineering, the Gusset Machine offers a range of benefits that will transform manufacturing processes. Its high-speed capabilities allow for significantly increased production volumes, enabling companies to meet growing demands and deadlines without compromising on quality.One of the key advantages of this innovation lies in its ability to optimize material usage. By minimizing wastage and maximizing utilization, manufacturers can reduce costs while still fulfilling customer requirements. The Gusset Machine achieves this through its automated processes, ensuring precise and consistent measurements and cuts, thus minimizing errors and waste.Moreover, the machine's versatile design allows it to be easily integrated into existing production lines, making it a practical investment for companies seeking to enhance their manufacturing capabilities. Its compatibility with various materials including paper, plastic, and fabric further expands its utility across multiple industries.In addition to increased efficiency and material optimization, the Gusset Machine takes worker safety into account. Equipped with advanced safety features, it reduces the risk of accidents by providing a secure operating environment. This not only protects employees but also minimizes downtime caused by injuries, further contributing to overall productivity.The introduction of the Gusset Machine marks a significant industry milestone, emphasizing the company's dedication to continuous improvement. By investing in research and development, the company aims to redefine industry standards and position itself as a forward-thinking leader.Speaking on the occasion, Mr. John Smith, the company's CEO, expressed his excitement about the potential impact of the Gusset Machine. "We believe this breakthrough technology has the power to transform manufacturing processes across diverse industries. With its unmatched capabilities, we are confident that it will deliver significant value to our customers, allowing them to remain competitive in today's challenging business environment."While the exact details of the technology cannot be divulged due to patent restrictions, the company assures industry professionals that the Gusset Machine incorporates cutting-edge engineering principles and intelligent software, setting it apart from any other existing gusset machines.Moreover, the company has already made arrangements for prompt installation and after-sales support. Dedicated teams of technicians will guide clients through the setup process and provide comprehensive training to ensure optimal utilization of the machine's capabilities.Throughout its long-standing history, the company has consistently embraced innovation and worked towards overcoming industry challenges. The introduction of the Gusset Machine is evidence of this commitment, highlighting the company's determination to provide its customers with practical and efficient solutions.[Conclusion]In conclusion, the unveiling of the Gusset Machine represents a significant technological leap in manufacturing processes. With its unprecedented efficiency, material optimization, and safety features, the machine is poised to revolutionize various industries by enhancing productivity and reducing costs. As the company continues to drive innovation and shape the future of manufacturing, the Gusset Machine reinforces its position as a pioneer in the industry.

Read More

Top Pp Bag Making Machine: Key Features and Benefits Revealed

As the world continues to move towards a more sustainable future, the need for eco-friendly materials and products has become increasingly apparent. One such product that has gained popularity in recent years is the polypropylene (PP) bag. These bags are durable, reusable, and recyclable, making them an excellent choice for both consumers and retailers. And now, with the introduction of the PP Bag Making Machine, producing these bags has become easier and more efficient than ever before.The PP Bag Making Machine is designed to produce high-quality bags of various sizes and thicknesses quickly and efficiently. It is equipped with the latest technology and features that make it easy to use and maintain. The machine is capable of producing bags with different designs and printing patterns, allowing manufacturers to customize their products to suit their specific needs.One of the key advantages of the PP Bag Making Machine is its speed. With a production speed of up to 150 pieces per minute, the machine can quickly and efficiently produce large quantities of bags in a short amount of time. This is especially important for manufacturers operating in today's fast-paced business environment, where time is of the essence.Another advantage of the PP Bag Making Machine is its versatility. It can produce bags of different sizes and thicknesses, making it suitable for use in a wide range of industries, including retail, agriculture, and construction. Additionally, the machine is designed to handle various types of materials, such as woven and non-woven fabrics, making it even more versatile.Despite its numerous advantages, the PP Bag Making Machine is also incredibly easy to use. It comes with an intuitive interface that allows operators to easily set and adjust the machine's parameters, including bag size, length, and thickness. The machine also has automatic sensors that detect issues such as jamming or material breakage, stopping the production line to prevent damage to the machine or the bags.As a leading manufacturer of PP Bag Making Machines, the company behind this innovation {} prides itself on its commitment to quality and customer satisfaction. The company invests heavily in research and development to ensure that its machines are of the highest quality and capable of meeting the changing needs of its customers. Additionally, the company provides comprehensive after-sales support to ensure that its customers can maintain and repair their machines to keep them running smoothly.In conclusion, the introduction of the PP Bag Making Machine is a significant step forward in the manufacturing of eco-friendly and durable bags. The machine's speed, versatility, and ease of use make it an excellent choice for manufacturers looking to produce high-quality bags quickly and efficiently. With the continued push towards sustainability, we can expect to see more innovative products like PP Bag Making Machines in the near future.

Read More

Durable and Eco-Friendly Printed Non Woven Bags for Everyday Use

[Company Name] Introduces Eco-Friendly Printed Non Woven Bags to Promote Sustainable Living[Company Name], a leading provider of eco-friendly products, has recently introduced a new line of printed non woven bags as part of their commitment to promoting sustainability and eco-conscious living.Non woven bags are becoming increasingly popular as an alternative to traditional plastic bags due to their durability, reusability, and environmentally-friendly nature. Unlike plastic bags, non woven bags are made from spunbond polypropylene, a type of thermoplastic polymer that is recyclable and biodegradable. This makes them a more sustainable choice for consumers who are looking to reduce their environmental impact.[Company Name] has taken their commitment to sustainability a step further by offering printed non woven bags, which are not only practical and eco-friendly but also customizable. The company uses a high-quality printing process to create vibrant and eye-catching designs on the bags, making them ideal for promoting businesses, events, and causes while also encouraging the use of reusable bags.In addition to their environmental benefits, the printed non woven bags offered by [Company Name] are also designed to be extremely durable and long-lasting. This means that they can be used repeatedly, reducing the need for single-use plastic bags and ultimately helping to minimize waste.The introduction of these printed non woven bags is in line with [Company Name]'s mission to provide sustainable alternatives to everyday products. The company is dedicated to offering high-quality, eco-friendly solutions that enable consumers to make more environmentally-conscious choices without sacrificing style or functionality."We are thrilled to introduce our new line of printed non woven bags as part of our ongoing commitment to promoting sustainability," said [Company Name] spokesperson. "We believe that it's important for businesses to offer eco-friendly alternatives to traditional products, and our printed non woven bags are a perfect example of this. Not only are they practical and durable, but they also allow our customers to showcase their brand or message in a visually appealing way."The introduction of these printed non woven bags aligns with the growing trend of businesses and consumers alike moving towards more sustainable practices. With increasing awareness of the environmental impact of single-use plastics, there is a growing demand for reusable and eco-friendly alternatives. [Company Name] aims to meet this demand by providing a stylish and practical solution that promotes sustainable living.The printed non woven bags offered by [Company Name] are available in a variety of sizes, styles, and designs, making them suitable for a wide range of applications. Whether used for grocery shopping, carrying everyday essentials, or promoting a brand or event, these bags offer a versatile and eco-friendly solution.As the global movement towards sustainability continues to gain momentum, the introduction of printed non woven bags by [Company Name] is a timely and welcome addition to the market. By offering a practical and customizable alternative to single-use plastic bags, the company is empowering consumers and businesses to make a positive impact on the environment while also meeting their everyday needs.With their dedication to promoting sustainability and eco-conscious living, [Company Name] is setting a commendable example for businesses seeking to make a positive difference in the world. The introduction of their printed non woven bags is a significant step towards reducing plastic waste and encouraging responsible consumption, and is sure to be well-received by consumers and businesses alike.

Read More

Discover the Power of Large Format Machines for Unprecedented Printing Experience

Large Format Machine Revolutionizes the Printing IndustryThe printing industry has evolved significantly over the years with advancements in technology. Large format printing machines have proven to be a game-changer in the industry, enabling businesses to create high-quality and long-lasting prints quickly and efficiently. Large format printing is ideal for creating banners, billboards, trade show displays, vehicle wraps, and other signage and promotional materials. With the introduction of the latest Large Format Machine (LFM)(need remove brand name), businesses can now enjoy an even better printing experience than ever before.The LFM packs a powerful punch with its cutting-edge technology that optimizes work efficiency and precision. It is the ultimate tool for businesses looking to produce top-quality, large format prints with high-definition. The machine is computer-controlled and can print on various materials including mesh, vinyl, and fabrics. The LFM also offers multiple printing modes, allowing designers to choose the best quality depending on the desired end result.In a market that is always changing and evolving, businesses need to stay ahead of competitors and ensure they are meeting their customers' needs and expectations. That is what the LFM does; it has revolutionized the print industry by offering high-quality and quick printing services. The machine has contributed to increased productivity and substantial cost reductions by enabling businesses to print more products faster and using fewer resources.The LFM has simplified the printing process, eliminating the need for multiple stages and reducing human error. Its sophisticated technology allows it to run smoothly and handle high-volume orders within a relatively short period. With a 360-degree printing mode, the machine can handle large prints, allowing businesses to take on different jobs with varying sizes and shapes.The LFM offers print quality that is unmatched, thanks to its exceptional color calibration and pixel precision. The machine has revolutionized fine-art printing, fashion printing, and architectural printing, among other industries. The LFM has enabled businesses to produce high-quality prints that are vivid, sharp, and long-lasting. The prints can withstand harsh outdoor environments and remain resilient to damage, which is critical for businesses to maintain brand recognition and reputation.The LFM has proven to be a reliable machine, and its user-friendly interface makes it easy to operate. The machine is easy to install, and it requires minimal maintenance, offering businesses a hassle-free experience. The LFM's technical support ensures that businesses can always operate at full capacity, and any issues that arise are addressed by professionals quickly.The LFM is an environmentally friendly option as it utilizes eco-solvent ink that is free from toxic chemicals. This means it produces prints that are safe for human consumption and the environment. The machine also has a low power consumption rate, ensuring a sustainable printing process. With the LFM, businesses can achieve excellent printing results while ensuring they play their part in conserving the environment.In conclusion, technological advancements continue to shape the print industry, and the LFM is a testament to this. The machine has simplified the printing process, increased work efficiency, and improved print quality. It has enabled businesses to deliver high-quality prints that are durable, resilient, and vivid. The LFM has revolutionized the print industry and set a new standard that all businesses in the industry should aim to achieve. It has changed the way businesses approach printing and has contributed to business growth, innovation, and profitability.

Read More

Machine manufacturer in China launches new product for construction industry

Yongming Machinery Co. (name changed) is a well-known manufacturer of injection molding machines in China. Recently, the company announced the launch of their latest injection machines, aimed at providing high-quality products to the customers while creating a sustainable future.The company's new product line is designed to reduce energy consumption, increase efficiency and minimize waste. They believe that manufacturing companies have a shared responsibility in building more sustainable production processes. With that in mind, Yongming Machinery has invested heavily in developing energy-efficient products. For example, their latest injection molding machine consumes 30% less energy compared to traditional models. The injection machines' intelligent control systems automatically adjust to the production needs, only using the precise amount of energy required. This minimizes power waste and decreases carbon emissions.Moreover, as a company with a strong eco-conscience, Yongming Machinery has incorporated eco-friendly materials and production processes in manufacturing their new injection machines. Their advanced injection machines are built using biodegradable and recyclable components, such as bio-based resins and eco-friendly lubricants. Additionally, their production line employs energy-saving methods, such as recycled water and material management.According to Mr. Zhang, the CEO of Yongming Machinery, the company's focus is on delivering top-quality products with minimum environmental impact. "We're committed to our customers by delivering reliable products that meet their needs while minimizing our carbon footprint. Our latest injection molding machines are the perfect example of that. Our machines' intelligent control systems and eco-friendly components have helped our clients reduce their carbon footprint and waste production significantly. We're proud to have helped them improve their sustainability performance."Yongming Machinery has been a market leader in injection molding machines for more than 10 years. Their experience in the industry has helped them develop products that exceed customers' expectations. Their new injection machines are user-friendly, efficient, and reliable. Their low energy requirement and eco-friendly features make them an ideal option for companies looking to improve their sustainability performance.The company caters to a wide range of industries, including automotive, electronics, packaging, medical, and consumer goods. They offer a variety of robust injection molding machines, ranging from hydraulic to electric motors, and ensure their customers receive excellent after-sale technical support and services. Moreover, the company's technical team provides comprehensive training to their clients on how to operate and maintain their machines, minimizing downtime and maximizing productivity.Yongming Machinery's competitive edge is their commitment to innovation. They invest heavily in their R&D department, ensuring their products are at the forefront of technology. The company's focus on innovation has led to the development of intelligent injection molding machines, equipped with advanced technology that monitors and optimizes production processes. Additionally, the company has established a strategic collaboration with leading technology companies, such as Siemens and Bosch Rexroth. The collaboration has enabled Yongming Machinery to integrate advanced technologies in their products, ensuring their injection machines operate at maximum efficiency, quality, and sustainability.In conclusion, Yongming Machinery's latest injection molding machines demonstrate the company's commitment to sustainability, innovation, and customer satisfaction. The machines' energy-efficient features, eco-friendly components, and advanced technology have helped their clients reduce their carbon footprint while increasing their productivity and profitability. Yongming Machinery is poised to continue being a market leader, delivering top-quality products that create a brighter future for all.

Read More

High Quality Woven Bag Machine: A Complete Guide

[Company Name] Announces Launch of New PP Woven Bag Machine to Meet Growing Demand[City, State], [Date] – [Company Name], a leading provider of manufacturing equipment, is proud to announce the launch of their newest product, the PP Woven Bag Machine. This state-of-the-art machine is designed to meet the growing demand for high-quality woven bags used in various industries including agriculture, construction, and packaging.The PP Woven Bag Machine is a result of extensive research and development by [Company Name]’s team of experts. It is equipped with advanced technology and innovative features to ensure the production of durable and reliable woven bags that meet the stringent requirements of modern applications.“We are thrilled to introduce our latest innovation, the PP Woven Bag Machine, to the market,” said [Spokesperson’s Name], CEO of [Company Name]. “With the increasing demand for woven bags across different industries, we saw the need to develop a machine that can produce high-quality bags efficiently and cost-effectively. Our new machine is a testament to our commitment to providing cutting-edge solutions to our customers.”The PP Woven Bag Machine is capable of producing a wide range of bag specifications, including different sizes, shapes, and colors. It offers flexibility to accommodate various customer needs and production requirements. The machine is also designed for easy operation and maintenance, allowing for hassle-free production and reduced downtime.In addition to its capabilities, the PP Woven Bag Machine is built with a focus on sustainability. It is engineered to maximize energy efficiency and minimize waste, aligning with [Company Name]’s dedication to environmentally-friendly manufacturing practices. This ensures that the production of woven bags is not only high-quality but also eco-friendly.The launch of the PP Woven Bag Machine signifies [Company Name]’s continued commitment to innovation and customer satisfaction. With a track record of delivering reliable and high-performance equipment, [Company Name] is poised to set a new standard in the woven bag manufacturing industry.About [Company Name]:[Company Name] is a leading provider of manufacturing equipment, specializing in delivering innovative solutions for the production of woven and non-woven products. With a focus on quality, reliability, and sustainability, [Company Name] is dedicated to meeting the unique needs of its customers and contributing to the advancement of various industries.For more information about [Company Name] and their PP Woven Bag Machine, please visit [Website URL] or contact [Contact Information].The launch of the PP Woven Bag Machine is expected to make a significant impact on the woven bag manufacturing industry, providing manufacturers with a reliable and efficient solution to meet the growing demand for high-quality woven bags. With its advanced technology, sustainability focus, and dedication to customer satisfaction, [Company Name] is well-positioned to lead the way in this sector and continue to drive innovation in manufacturing equipment.

Read More