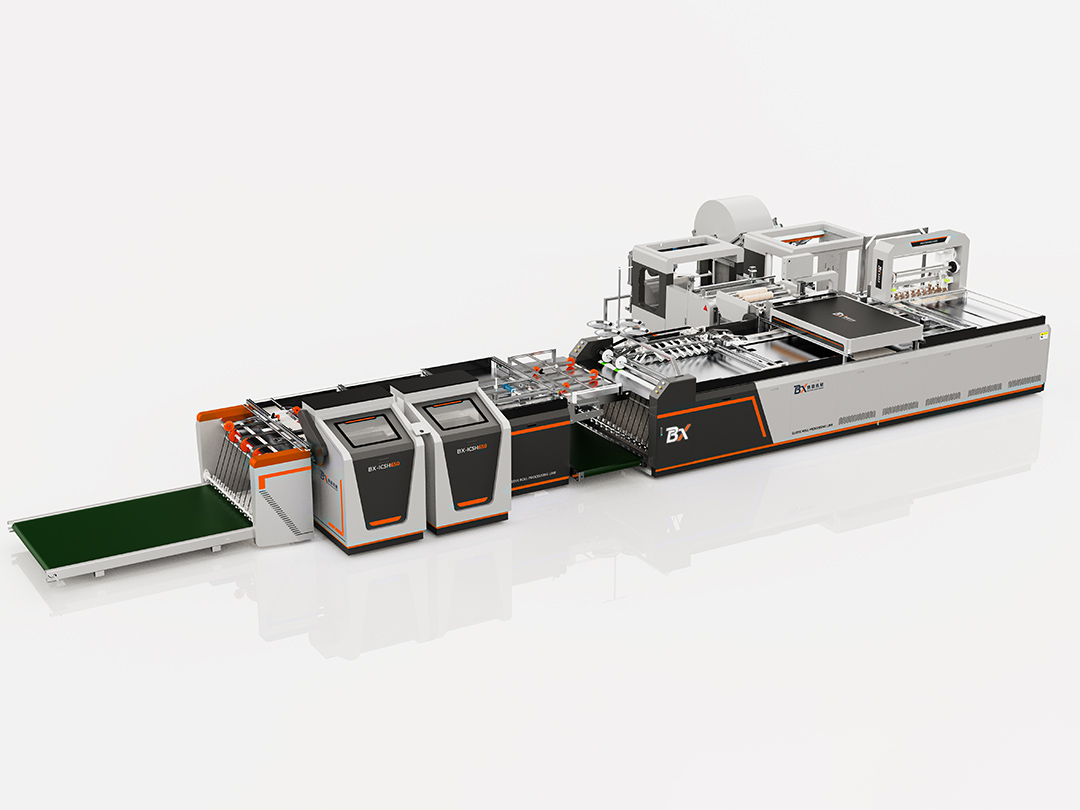

| Item | Parameter |

| Suitable Materials | Woven Fabric, Paper, Non-Woven |

| Color | Two sides 12 colors (6+6) or less, Color Printing |

| Max. Fabric width | 800mm |

| Max. printing area(L x W) | 1000 x 720mm |

| Max. bag making size (L x W) | 1250 x 800mm |

| Thickness of Printing Plate | 4mm or 7mm |

| Printing Roller | Φ320 |

| Anilox Roller | 220DPI(220 lines per square inch) |

| Printing Speed | 100-150m/min |

| Registration Type | Auto Registration System of Vertical Direction for 360° |

| Registration Valuation | ≤0.02mm |

1. Single-Pass, two side printing

2. High Precision Color Positioning , CI type & Direct Printing for Color (image) Printing

3. No-stop Fabric Roll Switch-over

4. No Roller Change needed for Different Printing Sizes

5. Edge Position Control (EPC) for Unwinding, the Second Printing Unit and Rewinding

6. Corona System for two-sides treatment

7. Automatic tension control

8. Auto Recirculation/Mixing System for Paint Mixture

9. Center Oven for complete drying

10. Main Motor Driving with Inverter Control, sync printing

11. PLC Operation Control, Digital Display for Operation Monitor and Operation Setting

1/We have many experience on PP woven bag industry 2/We can customize special hardware as customer demand. 3/Technical service for assembling. 4/Variety types for selection, prompt deliver. 5/Well-equipped with extensive sales network. 6/Advanced Production equipment and production technique. 7/Competitive Price (Factory direct price) with our good service. 8/Different designs are available according to customer requests. 9/Excellent quality testing equipment, 100% inspection on critical .