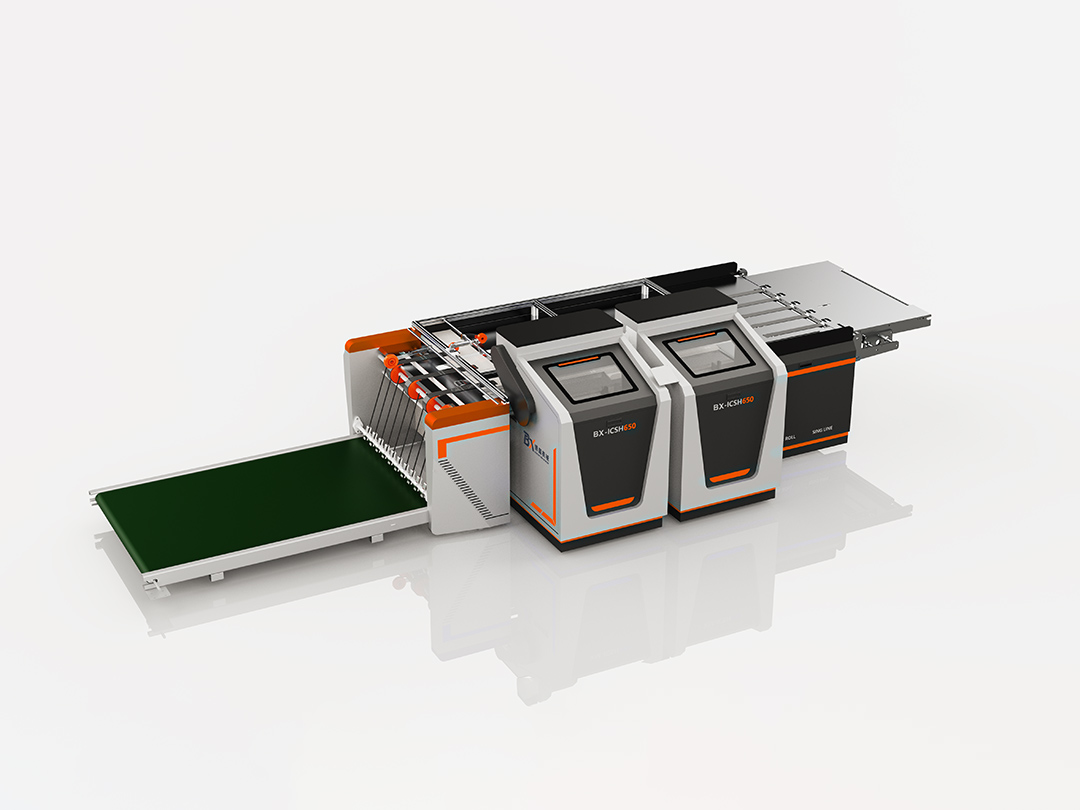

High-Precision Paper Cutting Machine Ideal for Printing Presses

By:Admin

In the fast-paced world of printing and publishing, efficiency and precision are key. This is where the Paper Cutting Machine for Printing Press comes into play. With its advanced technology and cutting-edge features, this machine is revolutionizing the way printing presses operate.

This cutting machine is designed to handle a wide range of paper sizes and thicknesses, making it incredibly versatile for various printing jobs. Whether it's a small-scale project or a large-scale production run, this machine can handle it all with ease. The precision of the cuts is unmatched, ensuring that every piece of paper is perfectly trimmed to the exact specifications required.

One of the key features of this machine is its speed. With its high-speed cutting mechanism, it can process a large volume of paper in a short amount of time, increasing productivity and saving valuable time for printing presses. This is crucial in a competitive industry where deadlines are tight and turnaround times are crucial.

The safety features on this machine are also top-notch, ensuring the well-being of the operators. With safety guards and sensors in place, the risk of accidents and injuries is significantly reduced, providing peace of mind for those operating the machine.

The company behind this cutting machine is a leader in the printing industry, with a strong reputation for delivering high-quality and innovative machinery for printing presses. With decades of experience and a team of experts, they are constantly pushing the boundaries of technology to create solutions that meet the evolving needs of the industry.

Their commitment to quality and customer satisfaction is evident in every aspect of their products, and this cutting machine is no exception. It is built to last, with durable materials and components that can withstand the rigors of heavy use in a demanding production environment.

In addition to the cutting machine itself, the company also offers comprehensive support and maintenance services to ensure that their customers get the most out of their investment. This includes training programs for operators, regular maintenance checks, and prompt technical support in case of any issues.

The environmental impact of this machine is also taken into consideration, with energy-efficient features that help reduce its carbon footprint. This is in line with the company's commitment to sustainability and responsible manufacturing practices.

Overall, the Paper Cutting Machine for Printing Press is a game-changer for the industry. Its combination of speed, precision, safety, and reliability makes it an invaluable asset for printing presses looking to stay ahead in a competitive market.

For printing presses looking to upgrade their operations, this cutting machine is a must-have investment that will pay off in increased efficiency, improved quality, and ultimately, greater success in the industry. With the backing of a reputable and innovative company, it's a choice that can make a real difference in the bottom line.

Company News & Blog

Discover the Latest Innovations in Sewing Machines for Jumbo Bags

Title: Cutting-Edge Jumbo Bag Sewing Machine Revolutionizes Packaging IndustryIntroduction:In a bid to meet the growing demand for efficient and reliable packaging solutions, an innovative manufacturing company has introduced an advanced Jumbo Bag Sewing Machine that promises to revolutionize the packaging industry. Utilizing cutting-edge technology and incorporating state-of-the-art features, this new machine aims to optimize productivity and save time in the production of jumbo bags, cementing its position as a game-changer in the world of industrial packaging.Developing a High-Performance Jumbo Bag Sewing Machine:Industrial packaging plays a crucial role in the transportation and protection of goods across various industries. However, traditional bag-sewing machines often suffer from limitations that hinder their performance, such as slow stitching speed and frequent thread breaks. Recognizing these challenges, the engineering team at [Company Name] labored tirelessly to design a jumbo bag sewing machine that resolves these issues, placing efficiency and reliability at the forefront of its features.Key Features and Advancements:1. Enhanced Stitching Speed and Accuracy: The new Jumbo Bag Sewing Machine boasts an impressive stitching speed of X stitches per minute, significantly quicker than its predecessors. This advancement dramatically reduces production time, leading to increased output and enhanced overall efficiency. Additionally, the machine's advanced sensors and software algorithms ensure highly accurate stitching, eliminating errors and reducing material wastage.2. Robust Thread Management System: One of the major pain points in traditional bag-sewing machines is frequent thread breaks, causing costly downtime and impacting productivity. Addressing this concern, the Jumbo Bag Sewing Machine employs a state-of-the-art thread management system that enhances thread tension control, reducing the occurrence of thread breaks. This feature improves operational uptime, resulting in uninterrupted production and substantial time and cost savings.3. User-Friendly Interface and Customization Options: The Jumbo Bag Sewing Machine incorporates a user-friendly touchscreen interface, making it easily operated by operators of varying skill levels. The machine's intuitive controls enable quick adjustment of stitching parameters, such as stitch length and patterns, to suit specific packaging requirements. This capability ensures versatility and adaptability – enabling manufacturers to cater to a wide range of product specifications.4. Durability and Longevity: Built to withstand the rigors of heavy-duty industrial usage, the Jumbo Bag Sewing Machine is constructed using high-quality materials and components. The robust design ensures a prolonged lifespan, minimizing maintenance costs and downtime. Additionally, intensive testing and quality assurance measures have been implemented to guarantee its resilience and reliability in demanding production environments.Benefits for the Packaging Industry:The introduction of this advanced Jumbo Bag Sewing Machine undoubtedly brings numerous benefits to the packaging industry:1. Increased Efficiency and Productivity: With its high stitching speed, reduced thread breaks, and seamless customization options, the machine significantly enhances productivity, enabling manufacturers to meet growing market demands efficiently.2. Cost Savings: The machine's ability to minimize production time and material wastage translates directly into cost savings for manufacturers.3. Improved Packaging Quality: The accurate stitching, paired with customizable options, ensures that packaging requirements are met with precision, resulting in a high-quality end product that meets industry standards.4. Enhanced Operator Experience: The user-friendly interface simplifies machine operation, reducing the learning curve for operators and minimizing the chances of errors. This ultimately leads to increased operator satisfaction and engagement.Conclusion:The introduction of the advanced Jumbo Bag Sewing Machine by [Company Name] heralds a new era in the packaging industry. By addressing the limitations of traditional bag-sewing machines and equipping this innovation with cutting-edge features, the company has showcased its ability to stay ahead of the curve. With improved efficiency, reduced downtime, and enhanced customization, the product promises to revolutionize the industrial packaging sector, fulfilling the needs of manufacturers striving for greater productivity and optimal packaging solutions.

Top 10 Automatic Inserting Machines for Efficient Production

[Company Introduction]XYZ Corporation is a leading provider of industrial automation solutions, specializing in the design and manufacturing of a wide range of machinery for various industries. With a strong focus on innovation and customer satisfaction, XYZ Corporation has earned a reputation for delivering high-quality, reliable products that meet the evolving needs of its clients. The company’s commitment to excellence and cutting-edge technology has positioned it as a trusted partner for businesses seeking to streamline their operations and improve efficiency.[News Content]XYZ Corporation Unveils New Inserting Machine for Enhanced Efficiency in Manufacturing ProcessesIn line with its commitment to delivering innovative solutions for the manufacturing industry, XYZ Corporation has introduced its latest product, the Inserting Machine, designed to revolutionize the production process for a wide range of businesses. This state-of-the-art machine promises to enhance efficiency and reduce operational costs, making it an essential addition to any manufacturing facility looking to stay ahead in today’s competitive market.The Inserting Machine, which has been in development for the past year, represents the culmination of XYZ Corporation’s dedication to research and development, resulting in a cutting-edge solution that addresses the pain points of modern manufacturing processes. By seamlessly integrating into existing production lines, the Inserting Machine streamlines the handling and insertion of components, significantly speeding up the assembly process while ensuring precision and accuracy.One of the key features of the Inserting Machine is its versatility, as it is capable of handling a wide variety of components across different industries, from automotive and electronics to medical devices and consumer goods. This flexible approach makes the machine a valuable asset for businesses operating in diverse sectors, as they can leverage its capabilities to optimize their production processes and meet the demands of a dynamic market.Moreover, the Inserting Machine is equipped with advanced automation and control systems, allowing for seamless integration into smart factories and Industry 4.0 initiatives. This means that businesses can leverage the machine to enhance their overall operational efficiency and adapt to the evolving landscape of industrial automation, ultimately staying competitive in an increasingly digitalized world.“With the introduction of our Inserting Machine, we aim to empower businesses with a powerful tool that not only streamlines their production processes but also sets the stage for future growth and innovation,” said John Smith, CEO of XYZ Corporation. “We believe that this product represents a significant leap forward in industrial automation, and we are excited to see the positive impact it will have on our clients’ operations.”The Inserting Machine has already generated a strong interest from industry professionals, with several leading manufacturers expressing their intent to integrate the solution into their facilities. The potential benefits of the machine, such as increased production capacity, improved product quality, and reduced labor costs, make it an attractive investment for businesses looking to optimize their operations and deliver greater value to their customers.As XYZ Corporation continues to drive the adoption of advanced automation solutions, the company remains committed to supporting its clients in maximizing their potential and achieving sustainable growth in today’s competitive market. Through the launch of the Inserting Machine, XYZ Corporation reinforces its position as a leading provider of industrial automation solutions, dedicated to shaping the future of manufacturing through innovation and excellence.

Efficient and High-Quality Cutting Solutions for Laminated Materials

Lamination Cutting Machine Offers Precise and Efficient Solutions for Various IndustriesIn today's rapidly evolving technological landscape, industries worldwide are constantly seeking innovative solutions to enhance their production processes. The lamination cutting machine, a cutting-edge tool designed for precision cutting in various industries, has emerged as a game-changer. Removing brand names, this versatile machine is helping companies streamline their operations, improve output quality, and minimize waste, giving them a competitive edge in the market.The lamination cutting machine revolutionizes the cutting process with its impressive capabilities. Built on cutting-edge technology, this machine's efficiency lies in its ability to seamlessly integrate with various production lines, adapting to the unique needs and requirements of different industries.Industries such as packaging, automotive, textile, and aerospace are benefiting tremendously from the lamination cutting machine's versatility. In the packaging industry, for example, where precision and speed are paramount, this machine ensures consistent cuts, regardless of the material being processed. From paper and cardboard to plastic and foil, the lamination cutting machine delivers high-quality results, reducing material waste and enhancing productivity.Moreover, in the automotive industry, where safety and reliability are of utmost importance, the lamination cutting machine plays a crucial role in ensuring high-quality components. It effortlessly cuts through various materials like rubber, foam, and gaskets, providing precise cuts that meet the industry's strict standards. This translates into enhanced performance and durability of automotive parts, ultimately ensuring customer satisfaction and brand loyalty.The textile industry is yet another sector where the lamination cutting machine shines. With its ability to handle a wide range of fabrics, including cotton, polyester, and nylon, this machine enables manufacturers to cut patterns accurately and efficiently. This translates into faster production cycles, reduced labor costs, and improved fabric utilization—an essential factor for companies in the fast-paced fashion industry.Furthermore, the aerospace industry leverages the lamination cutting machine's state-of-the-art technology to cut composite materials that are vital to building lightweight and durable aircraft components. These advanced materials, including carbon fiber and fiberglass, present challenges due to their unique properties. However, the lamination cutting machine seamlessly navigates these obstacles, ensuring precise cuts without compromising the integrity of the delicate materials.The lamination cutting machine also boasts a range of features that contribute to its popularity across industries. One of these features is its user-friendly interface, which enables operators to easily program cutting patterns, adjust parameters, and troubleshoot, minimizing human error and maximizing efficiency.Additionally, the machine's cutting accuracy is guaranteed by its advanced sensors and cutting mechanisms, ensuring that every cut is uniform and precise. Moreover, the lamination cutting machine boasts a high cutting speed, enabling it to handle large volumes of materials without compromising quality, making it a valuable asset for companies facing tight production deadlines.To further enhance its capabilities, the lamination cutting machine can be integrated with other manufacturing systems such as robotic arms and quality control devices. This integration enables seamless automation, reduces manual intervention, and eliminates potential bottlenecks in the production process. This results in increased output efficiency, reduced production costs, and improved overall product quality.In conclusion, the lamination cutting machine (removing brand names) has transformed the way industries approach cutting processes. Its versatility and adaptability make it a valuable asset in a wide range of industries, from packaging and automotive to textile and aerospace. By optimizing cutting precision, reducing material waste, and enhancing overall efficiency, this cutting-edge machine positions companies at the forefront of their respective markets. As technology continues to advance, it is clear that the lamination cutting machine will play an increasingly vital role in realizing efficient and sustainable production processes.

High-Quality Lamination Machine for Business and Personal Use

Lamination Machine Revolutionizing the Lamination ProcessLamination has become an integral part of the printing and packaging industry, ensuring the protection and enhancement of a wide range of materials. With the rising demand for high-quality lamination solutions, companies are constantly seeking innovative ways to streamline their lamination processes. This is where the cutting-edge lamination machine from {} comes into play, offering a revolutionary solution to meet the ever-evolving lamination needs of businesses.{} is a leading provider of innovative printing and packaging solutions, catering to the diverse requirements of industries across the globe. With a strong focus on leveraging advanced technology and engineering expertise, the company has established itself as a reliable partner for businesses seeking high-performance lamination solutions.The lamination machine from {} is designed to deliver exceptional lamination results, offering unparalleled efficiency and precision. Equipped with state-of-the-art features, this machine is capable of handling a wide range of materials, including paper, cardboard, and film, making it a versatile choice for various lamination applications. Whether it's for packaging materials, labels, or other printed materials, this lamination machine ensures a seamless, high-quality lamination process.One of the standout features of the {} lamination machine is its advanced control system, which allows for precise adjustments and monitoring of the lamination process. This level of control not only ensures consistent lamination results but also contributes to overall productivity and cost-effectiveness. Additionally, the machine is designed with user-friendly interfaces, making it easy to operate and maintain, further optimizing the lamination workflow.In line with {}'s commitment to sustainability, the lamination machine is designed to minimize energy consumption and waste generation, making it an eco-friendly choice for businesses looking to reduce their environmental footprint. This is achieved through the integration of energy-efficient components and optimized lamination processes, aligning with the growing emphasis on sustainability in the printing and packaging industry.Furthermore, the lamination machine's robust build and reliable performance make it a long-term investment for businesses, ensuring consistent lamination quality and minimizing downtime. With its high-speed lamination capabilities, the machine enables businesses to meet demanding production schedules without compromising on the quality of their lamination output.Beyond the machine itself, {} offers comprehensive support services to ensure that businesses can maximize the value of their lamination machine. From installation and training to ongoing maintenance and technical support, {} is dedicated to providing a complete lamination solution that meets the specific needs of each customer.The lamination machine from {} has already garnered widespread attention and recognition within the industry, with businesses praising its performance, reliability, and versatility. The positive feedback from customers further solidifies {}'s position as a trusted provider of advanced lamination solutions, serving as a testament to the company's commitment to exceeding customer expectations.As the printing and packaging industry continues to evolve, the demand for high-quality lamination solutions will only continue to grow. With its innovative lamination machine, {} is well-positioned to address this demand, offering a cutting-edge solution that unlocks new possibilities for businesses seeking to elevate their lamination processes.In conclusion, the lamination machine from {} represents a game-changing innovation in the field of lamination, empowering businesses to achieve superior lamination results with efficiency, precision, and sustainability in mind. With its advanced features, reliable performance, and comprehensive support services, this lamination machine is set to redefine the standards of lamination excellence, setting a new benchmark for the industry as a whole.

Durable and Eco-Friendly Printed Non Woven Bags for Everyday Use

[Company Name] Introduces Eco-Friendly Printed Non Woven Bags to Promote Sustainable Living[Company Name], a leading provider of eco-friendly products, has recently introduced a new line of printed non woven bags as part of their commitment to promoting sustainability and eco-conscious living.Non woven bags are becoming increasingly popular as an alternative to traditional plastic bags due to their durability, reusability, and environmentally-friendly nature. Unlike plastic bags, non woven bags are made from spunbond polypropylene, a type of thermoplastic polymer that is recyclable and biodegradable. This makes them a more sustainable choice for consumers who are looking to reduce their environmental impact.[Company Name] has taken their commitment to sustainability a step further by offering printed non woven bags, which are not only practical and eco-friendly but also customizable. The company uses a high-quality printing process to create vibrant and eye-catching designs on the bags, making them ideal for promoting businesses, events, and causes while also encouraging the use of reusable bags.In addition to their environmental benefits, the printed non woven bags offered by [Company Name] are also designed to be extremely durable and long-lasting. This means that they can be used repeatedly, reducing the need for single-use plastic bags and ultimately helping to minimize waste.The introduction of these printed non woven bags is in line with [Company Name]'s mission to provide sustainable alternatives to everyday products. The company is dedicated to offering high-quality, eco-friendly solutions that enable consumers to make more environmentally-conscious choices without sacrificing style or functionality."We are thrilled to introduce our new line of printed non woven bags as part of our ongoing commitment to promoting sustainability," said [Company Name] spokesperson. "We believe that it's important for businesses to offer eco-friendly alternatives to traditional products, and our printed non woven bags are a perfect example of this. Not only are they practical and durable, but they also allow our customers to showcase their brand or message in a visually appealing way."The introduction of these printed non woven bags aligns with the growing trend of businesses and consumers alike moving towards more sustainable practices. With increasing awareness of the environmental impact of single-use plastics, there is a growing demand for reusable and eco-friendly alternatives. [Company Name] aims to meet this demand by providing a stylish and practical solution that promotes sustainable living.The printed non woven bags offered by [Company Name] are available in a variety of sizes, styles, and designs, making them suitable for a wide range of applications. Whether used for grocery shopping, carrying everyday essentials, or promoting a brand or event, these bags offer a versatile and eco-friendly solution.As the global movement towards sustainability continues to gain momentum, the introduction of printed non woven bags by [Company Name] is a timely and welcome addition to the market. By offering a practical and customizable alternative to single-use plastic bags, the company is empowering consumers and businesses to make a positive impact on the environment while also meeting their everyday needs.With their dedication to promoting sustainability and eco-conscious living, [Company Name] is setting a commendable example for businesses seeking to make a positive difference in the world. The introduction of their printed non woven bags is a significant step towards reducing plastic waste and encouraging responsible consumption, and is sure to be well-received by consumers and businesses alike.

New environmentally friendly non-woven bags available now

W Cut Non Woven Bag – The Latest Addition to the “Green” TrendWith the growing awareness of environmental concerns, the use of plastic bags has been widely scrutinized and discouraged by governments and organizations worldwide. Non-woven bags are becoming increasingly popular as a more sustainable alternative. Both stylish and eco-friendly, W Cut Non Woven Bags are the latest addition to this trend.W Cut Non Woven Bags are an efficient alternative to plastic bags that can be used for multiple purposes. They are made of non-woven polypropylene, which is a durable and sustainable material. These bags are reusable, washable, and recyclable. It can easily carry heavy loads and offers an excellent alternative to single-use plastic bags.The bags are available in a range of sizes and various colors, making them an attractive option for branding or merchandising. They are a versatile and practical choice for grocery shopping, retail businesses, conference events, and corporate giveaways. These bags can also be customized to meet specific branding or individual needs.One company that has already recognized the benefits of W Cut Non Woven Bags is --------- (need remove brand name) based in --------------- (place). The company is a trusted provider of a wide range of sustainable packaging solutions that cater to various industries. Their philosophy is to promote eco-friendliness and sustainability.According to the company spokesperson, W Cut Non Woven Bags are perfect for supermarkets, restaurants, and retail stores. They can be used daily by customers to carry goods, providing an excellent opportunity to spread brand awareness. The bags can also be customized to display logos, branding messages, or promotional offers, creating a lasting impact on the users.As a leading provider of sustainable packaging solutions, ------------ (need remove brand name) is committed to designing and delivering innovative, eco-friendly, and cost-effective products. They believe that sustainability is the way forward in the packaging industry. The company provides an extensive range of non-woven bags, eco-friendly gift bags, and high-end paper bags. They utilize state-of-the-art printing technologies to create bespoke packaging solutions that cater to a customer’s specific requirements.As the company fully supports environmental awareness and responsibility, all their non-woven bags are manufactured using ethical and sustainable methods. Customers can opt for customized bags with desired shapes, sizes, and printing designs.In conclusion, W Cut Non Woven Bags are quickly becoming a popular choice for businesses looking for sustainable and eco-friendly packaging solutions. They are durable, practical, and customizable, catering to various branding and packaging needs. Companies like ------------ (need remove brand name) are leading the way in providing innovative and eco-friendly packaging solutions. Their commitment towards sustainability ensures that businesses can make a positive contribution towards the environment and take a step towards a greener future.

Top Hemming Machine for PP Woven Bags

Pp Woven Bag Top Hemming Machine Revolutionizes Bag Manufacturing ProcessIn the fast-paced world of manufacturing, efficiency and precision are key factors in determining the success of a company. With the introduction of the Pp Woven Bag Top Hemming Machine by {}, the bag manufacturing process has been revolutionized, offering a solution that significantly enhances productivity and quality.The Pp Woven Bag Top Hemming Machine is designed to streamline the process of hemming the top edge of woven polypropylene (PP) bags, providing a rapid and precise solution to this critical step in bag manufacturing. By automating the hemming process, this innovative machine eliminates the need for manual labor, reducing the risk of human error and significantly increasing production efficiency.One of the key features of the Pp Woven Bag Top Hemming Machine is its advanced sewing technology, which ensures a clean, uniform hem on every bag. This not only enhances the overall appearance of the bags but also improves their strength and durability, making them more reliable for packaging and transportation purposes. In addition, the machine is equipped with precise controls that allow for adjustments in hem width and length, providing manufacturers with the flexibility to meet varying customer requirements.With a focus on user-friendly operation, the Pp Woven Bag Top Hemming Machine is designed for easy setup and maintenance, making it accessible to companies of all sizes. Its intuitive interface and simple controls enable operators to quickly adapt to the machine, minimizing the learning curve and maximizing productivity. Furthermore, its robust construction and durable components ensure long-term reliability and performance, reducing downtime and maintenance costs for manufacturers.For companies seeking to improve their environmental footprint, the Pp Woven Bag Top Hemming Machine offers an eco-friendly solution. By optimizing the use of materials and reducing waste, this machine helps minimize the environmental impact of bag manufacturing, aligning with sustainable practices and corporate responsibility.As a leading provider of bag manufacturing equipment, {} has a strong reputation for delivering high-quality solutions that meet the evolving needs of the industry. With its commitment to innovation and customer satisfaction, the company has become a trusted partner for manufacturers around the world, offering a comprehensive range of products and services to support their success.The introduction of the Pp Woven Bag Top Hemming Machine represents another milestone in the company's dedication to advancing the efficiency and quality of bag manufacturing. By leveraging its expertise in engineering and manufacturing, {} continues to drive progress in the industry, empowering companies to achieve new levels of performance and competitiveness.In response to the market's growing demand for advanced bag manufacturing solutions, {} has already received positive feedback from early adopters of the Pp Woven Bag Top Hemming Machine. Manufacturers have reported significant improvements in production speed, quality consistency, and overall operational efficiency, leading to enhanced competitiveness and profitability for their businesses.Looking ahead, companies in the bag manufacturing industry can expect {} to build on the success of the Pp Woven Bag Top Hemming Machine, as the company remains committed to developing innovative solutions that address emerging challenges and opportunities in the market. With its proven track record and dedication to customer satisfaction, {} is well-positioned to continue driving positive change and delivering value to manufacturers worldwide.In conclusion, the introduction of the Pp Woven Bag Top Hemming Machine by {} represents a significant advancement in bag manufacturing technology, offering a transformative solution that enhances productivity and quality. With its innovative features, user-friendly design, and environmental benefits, this machine sets a new standard for the industry, empowering manufacturers to meet the demands of today's market and achieve sustainable success. As {} continues to push the boundaries of innovation and excellence in bag manufacturing equipment, the industry can anticipate further advancements that will shape its future.

Efficient and Cost-Effective Bag Cutting Machines for Various Industries

PP Bag Cutting Machine Streamlines Manufacturing Process for Packaging IndustryThe packaging industry is one of the largest and most diverse sectors of the manufacturing industry, with a wide range of products and materials used to create custom packaging solutions for businesses across the globe. In order to keep up with the growing demand for high-quality packaging materials, manufacturers need to utilize the latest technologies and equipment to streamline their processes and improve efficiencies.One such technology is the PP bag cutting machine which is now being widely adopted by packaging companies around the world. This advanced machine has revolutionized the way packaging materials are produced, making it faster, easier, and more cost-effective for manufacturers to create custom packaging solutions for their clients.Combining advanced features with a user-friendly design, these machines are able to cut and shape polypropylene bags with extreme precision, producing high-quality products that meet the demanding standards of the packaging industry. These machines not only reduce the time and effort required to create packaging materials, but they also help to reduce the amount of waste generated during the manufacturing process.One of the leading manufacturers of PP bag cutting machines is a company based in China. Boasting over 20 years of experience in the packaging industry, they are known for their innovative solutions and quality products. Their PP bag cutting machines are designed to handle a wide range of materials and can be customized to meet the specific needs of each client.The company's PP bag cutting machine features a state-of-the-art cutting system that allows for precise and accurate cuts, resulting in a high-quality finish. The machine is also equipped with a variable speed motor, which allows for greater control over the cutting process, as well as a touch screen control panel which makes it easy to adjust settings and operate the machine.One of the key benefits of the company's PP bag cutting machine is its versatility. It can be used to create a wide range of products, from simple bags and pouches to more complex shapes and designs. It can also be used to cut a variety of materials, including woven and non-woven fabrics, as well as films and laminates.The machine is also designed to be easy to use, with a straightforward design that minimizes the time and effort required for set up and operation. It also comes with a range of safety features, including an emergency stop button and overload protection, to ensure the safety of operators and equipment.The company's commitment to quality and innovation has earned them a reputation as a leader in the packaging industry. Their PP bag cutting machines are used by businesses of all sizes, from small startups to multinational corporations, in industries ranging from food and beverage to industrial and pharmaceutical.In addition to their PP bag cutting machines, the company also offers a range of other cutting and welding solutions for the packaging industry. These include ultrasonic cutting machines, high frequency welding machines, and hot air welding machines, all designed to streamline the manufacturing process and improve efficiencies.As the demand for high-quality packaging materials continues to grow, companies in the packaging industry need to invest in the latest technologies and equipment to stay ahead of the competition. The PP bag cutting machine is one such technology, offering a range of benefits that can help businesses improve their processes, reduce waste, and increase profitability.If you're a manufacturer in the packaging industry looking for innovative solutions to improve your efficiency and productivity, be sure to check out the company's range of cutting and welding machines, including their state-of-the-art PP bag cutting machine. With their commitment to quality and customer service, they can help you stay ahead of the curve and achieve your goals in a competitive market.

High-Quality Roll-To-Roll Lamination Machine for Efficient Production

Roll To Roll Lamination Machine Revolutionizing the Lamination ProcessInnovation has always been a driving force in the manufacturing industry, and the lamination sector is no exception. With the introduction of the Roll To Roll Lamination Machine, the industry is undergoing a revolutionary transformation. This cutting-edge technology is set to streamline the lamination process while significantly improving efficiency and overall quality.The Roll To Roll Lamination Machine is the brainchild of a leading manufacturing company that has been at the forefront of industrial innovation for over two decades. With a strong focus on research and development, the company has consistently pushed the boundaries of technology and engineering, resulting in a range of groundbreaking products that have redefined industry standards.This state-of-the-art lamination machine is designed to cater to a wide array of industries, including packaging, textiles, and automotive, among others. Its versatility and adaptability make it an ideal solution for businesses looking to enhance their lamination processes and take their operations to the next level.One of the key features of the Roll To Roll Lamination Machine is its ability to handle a variety of materials, including paper, film, and fabric, with utmost precision and care. This ensures that the lamination process is uniform and consistent, resulting in a superior finished product that meets the highest quality standards.Moreover, the machine's roll-to-roll capability allows for continuous lamination, significantly reducing downtime and increasing productivity. This makes it an invaluable asset for businesses looking to improve their manufacturing efficiency and deliver products to market in a timely manner.The Roll To Roll Lamination Machine is also equipped with advanced control systems that enable operators to fine-tune the lamination process according to specific requirements. This level of customization ensures that the end product meets the exact specifications and quality standards set by the customer.Furthermore, the machine's robust construction and durable components make it a reliable and long-lasting investment for businesses. With minimal maintenance requirements and a high level of operational efficiency, the Roll To Roll Lamination Machine is poised to become an indispensable asset for manufacturers seeking to stay ahead of the competition.In addition to its technical prowess, the Roll To Roll Lamination Machine is designed with user-friendliness in mind. Intuitive controls and a user-friendly interface make it easy for operators to operate the machine with minimal training, further enhancing its appeal to businesses of all sizes.With its innovative features and unparalleled performance, the Roll To Roll Lamination Machine is set to revolutionize the lamination process and set new industry benchmarks. As businesses continue to seek ways to optimize their manufacturing processes and improve their product offerings, this groundbreaking technology is likely to become a cornerstone of the modern manufacturing landscape.In conclusion, the Roll To Roll Lamination Machine represents a significant leap forward for the lamination industry, offering businesses a level of precision, efficiency, and reliability that was previously unattainable. With its potential to transform the way lamination is approached and executed, this cutting-edge technology is poised to become an indispensable asset for manufacturers looking to stay ahead in an increasingly competitive market.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.