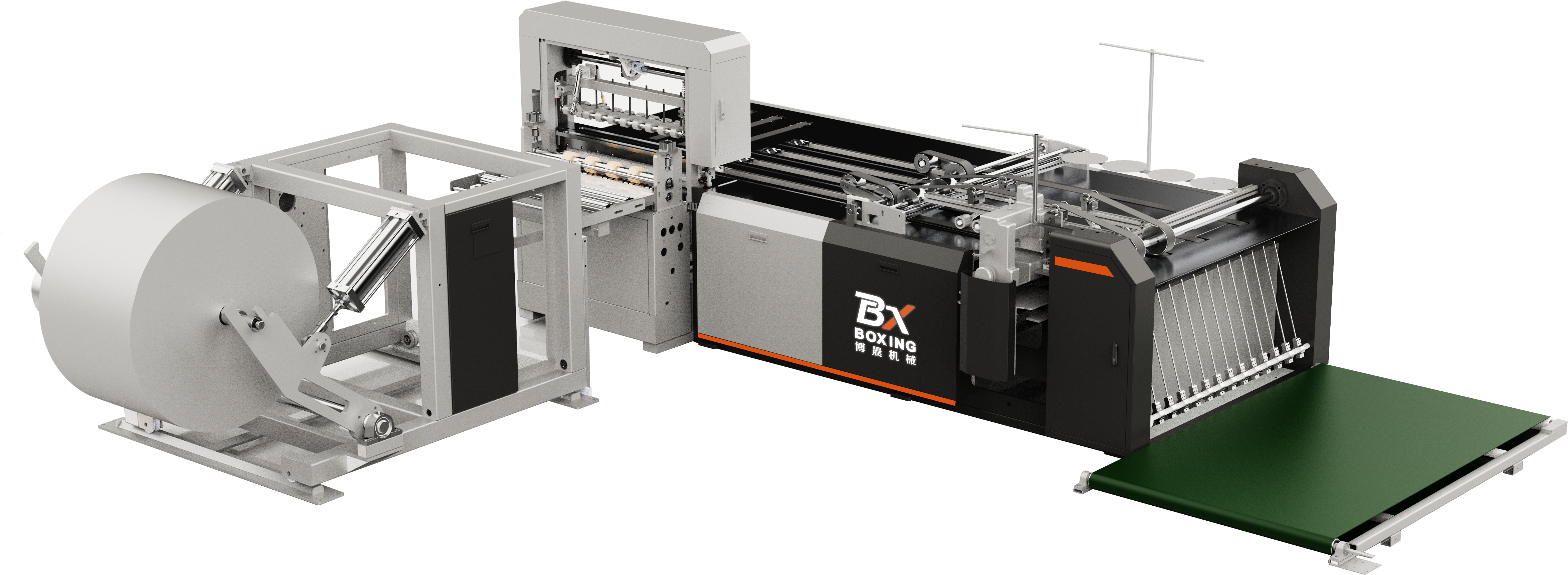

Top Hemming Machine for PP Woven Bags

By:Admin

In the fast-paced world of manufacturing and packaging, companies are constantly seeking new and innovative ways to improve efficiency and productivity. One company at the forefront of this industry is [company name], a leading provider of innovative packaging solutions. Their latest contribution to the industry is the cutting-edge PP Woven Bag Top Hemming Machine, a revolutionary piece of equipment that is set to redefine bag hemming technology.

The PP Woven Bag Top Hemming Machine is a state-of-the-art piece of equipment that is designed to streamline the process of hemming woven bags, significantly reducing production time and costs. This innovative machine is equipped with advanced technology that ensures precise and accurate hemming of PP woven bags, delivering a high-quality finished product every time.

With a strong focus on quality and efficiency, [company name] has developed this machine to meet the demands of modern manufacturing. The PP Woven Bag Top Hemming Machine is capable of handling a wide range of bag sizes and materials, making it a versatile solution for manufacturers in various industries. Whether it's food packaging, agricultural products, or construction materials, this machine can efficiently hem woven bags of all types.

One of the key features of the PP Woven Bag Top Hemming Machine is its user-friendly interface, which allows for easy operation and minimal training requirements. This user-friendly design ensures that manufacturers can seamlessly integrate this machine into their production processes, without the need for extensive retooling or workforce retraining.

Furthermore, the machine is equipped with advanced automation capabilities, allowing for continuous operation and minimal downtime. This ensures that manufacturers can maximize their production output and meet tight deadlines, ultimately improving their overall productivity and profitability.

In addition to its advanced technology and user-friendly design, the PP Woven Bag Top Hemming Machine is also built with durability in mind. Constructed from high-quality materials and engineered to withstand the rigors of industrial use, this machine is designed to deliver reliable performance for years to come.

As a company that is committed to driving innovation in the packaging industry, [company name] has invested heavily in research and development to bring the PP Woven Bag Top Hemming Machine to market. Their team of experienced engineers and technicians have worked tirelessly to design and perfect this machine, ensuring that it meets the highest standards of performance, quality, and reliability.

Furthermore, [company name] has a strong commitment to customer satisfaction, offering comprehensive support and service for their products. From installation and training to ongoing maintenance and technical support, they ensure that their customers have everything they need to make the most of their investment in the PP Woven Bag Top Hemming Machine.

In conclusion, the PP Woven Bag Top Hemming Machine represents a significant leap forward in bag hemming technology, offering manufacturers a cutting-edge solution to improve their production processes. With its advanced technology, user-friendly design, and exceptional durability, this machine is set to become an indispensable asset for companies in the manufacturing and packaging industry.

For more information about the PP Woven Bag Top Hemming Machine, visit [company website] or contact their customer service team. Don't miss out on the opportunity to revolutionize your production processes with this groundbreaking technology from [company name].

Company News & Blog

High Quality Pp Bag Making Machine for Efficient Production

In today's fast-paced and ever-changing world, the demand for high-quality packaging solutions continues to grow. As companies strive to meet the needs of their customers while also adhering to sustainability practices, the need for efficient and reliable packaging solutions has never been greater.One company that is at the forefront of providing cutting-edge packaging solutions is {}. With a strong focus on innovation and customer satisfaction, {} has established itself as a leading manufacturer of pp bag making machines. These state-of-the-art machines are designed to meet the growing demand for flexible and reliable packaging options.The pp bag making machines produced by {} are known for their precision, efficiency, and durability. These machines are capable of producing a wide range of pp bags, including shopping bags, food packaging bags, and industrial packaging bags. With a strong emphasis on quality control and technological innovation, {} has earned a reputation for delivering top-notch packaging solutions to its customers.One of the key features of {}'s pp bag making machines is their ability to produce bags that are not only durable and reliable but also environmentally friendly. With a focus on sustainability, {} has developed cutting-edge technologies that enable its machines to produce pp bags that are recyclable and biodegradable. This commitment to environmental responsibility has helped {} to stand out in the industry and has positioned the company as a leader in sustainable packaging solutions.In addition to their commitment to sustainability, {} is also dedicated to providing exceptional customer service. The company works closely with its clients to understand their specific needs and requirements, and then develops customized solutions to meet those needs. Whether a customer is looking for a small-scale pp bag making machine for a start-up business or a large-scale production line for a well-established company, {} has the expertise and the resources to deliver the right solution.With a strong emphasis on research and development, {} is constantly striving to improve and refine its pp bag making machines. The company invests heavily in the latest technologies and manufacturing processes to ensure that its machines are always at the forefront of innovation. By staying ahead of the curve, {} is able to provide its customers with the highest quality and most advanced packaging solutions on the market.As the demand for high-quality and sustainable packaging solutions continues to grow, {} is well-positioned to meet the needs of its customers. With its state-of-the-art pp bag making machines, commitment to sustainability, and dedication to customer service, {} is truly a leader in the packaging industry. Whether a company is looking to improve its existing packaging processes or is in need of a completely new solution, {} has the expertise and the resources to deliver the right solution.In conclusion, the demand for high-quality and sustainable packaging solutions is greater than ever. With its cutting-edge pp bag making machines, commitment to sustainability, and dedication to customer service, {} is well-positioned to meet the needs of its customers and is truly a leader in the packaging industry.

SEO Title: Shop the Ultimate Woven Printing Machine for Pp Material

Title: Innovative PP Woven Printing Machine Revolutionizes Manufacturing Industry Introduction (104 words):With the rapid advancements in technology, the manufacturing industry is witnessing remarkable transformations. One such groundbreaking innovation is the introduction of the state-of-the-art PP woven printing machine. This innovative device, developed by a leading company known for its dedication to excellence and cutting-edge solutions, promises to revolutionize the PP woven manufacturing process. By combining advanced printing capabilities with industry-leading efficiency, this machine is set to enhance productivity, reduce costs, and open new avenues for businesses operating in the PP woven industry. Paragraph 1 (117 words):The PP woven printing machine, developed by a renowned industry leader, marks a significant milestone in the manufacturing sector. By incorporating the latest printing technologies, this state-of-the-art machine offers unmatched precision and quality in the printing of PP woven products. Equipped with high-resolution digital printing systems, it allows for intricate designs, vibrant colors, and precise graphics to be printed on PP woven materials. This breakthrough technology ensures that businesses can meet the demands of modern consumers who seek eye-catching and visually appealing products. Moreover, the machine's fast-paced printing capabilities enable quick turnaround times, thus saving valuable production time and increasing overall efficiency for manufacturers.Paragraph 2 (128 words):In addition to its cutting-edge printing capabilities, the PP woven printing machine boasts an array of features that set it apart from traditional manufacturing equipment. With its automated workflow and user-friendly interface, operators can easily control and monitor the entire printing process, ensuring maximum output quality with minimal human error. Furthermore, the machine's robust construction and adherence to strict industry standards guarantee longevity and durability even in the most demanding production environments. This reliability translates into reduced maintenance costs and increased machine uptime, enabling businesses to meet market demands without interruptions. The machine's flexible design allows for customization, accommodating various PP woven product sizes and dimensions, resulting in enhanced versatility and adaptability.Paragraph 3 (155 words): The impact of the PP woven printing machine extends beyond its advancements in printing technology. By streamlining the manufacturing process, this innovative device introduces a series of benefits for businesses. Firstly, it enables manufacturers to reduce material wastage through optimized printing designs and configurations, paving the way for a more sustainable and eco-friendly production process. Additionally, the machine's efficiency and rapid production speed result in fewer production cycles, ultimately lowering energy consumption and minimizing the overall carbon footprint. As a result, businesses can align their operations with eco-conscious consumers and foster a more environmentally responsible image.Furthermore, the PP woven printing machine's ability to produce customized prints facilitates market differentiation and brand recognition. Manufacturers can now create unique and visually compelling products that stand out in a crowded marketplace, thereby gaining a competitive edge. The machine's versatility in accommodating different design requirements also enables businesses to meet individual customer preferences, further enhancing customer satisfaction and loyalty.Conclusion (107 words):The introduction of the cutting-edge PP woven printing machine represents an exciting development in the manufacturing industry. By combining advanced printing technologies with enhanced efficiency and flexibility, this innovative device promises to revolutionize the production of PP woven products. With its unparalleled printing quality, rapid turnaround times, and versatility, businesses can leverage this machine to meet the demands of modern consumers and establish a strong market presence. Furthermore, the PP woven printing machine's commitment to sustainability and eco-friendliness ensures that manufacturers can align their operations with the growing global emphasis on environmental responsibility. Overall, this innovation signifies a new era for the PP woven manufacturing sector, offering businesses endless possibilities for growth and success.

All You Need to Know About High-Quality Lamination Machines

Title: New Pp Lamination Machine Revolutionizes the Packaging IndustryIntroduction:In a world where packaging plays a crucial role in product presentation and protection, companies are constantly seeking innovative methods to enhance the durability and appeal of their packaging materials. Enter the revolutionary Pp Lamination Machine, a cutting-edge solution that promises to revolutionize the packaging industry. With its advanced technology and superior performance, this machine is set to transform the way packaging materials are manufactured and utilized, paving the way for increased efficiency and sustainability in the market. In the following article, we will explore the key features and benefits of the Pp Lamination Machine and delve into how it is reshaping the packaging landscape for businesses worldwide.I. Key Features of the Pp Lamination Machine:The Pp Lamination Machine boasts a range of impressive features that set it apart from traditional lamination processes. One of its standout features is its ability to apply a polypropylene (PP) film onto various substrates with precision and efficiency. This film not only enhances the visual appeal of the packaging material but also provides a protective layer that safeguards the product against external factors such as moisture, UV light, and mechanical stress.Moreover, the Pp Lamination Machine incorporates state-of-the-art adhesive materials that ensure a firm bond between the PP film and the substrate. This ensures the durability and longevity of the packaging, giving businesses confidence in their products' safety during transportation and storage.Additionally, this machine incorporates cutting-edge automation and control systems that streamline the entire lamination process. With user-friendly interfaces and programmable settings, operators can adjust parameters such as temperature, speed, and tension to achieve optimal lamination results consistently. This not only saves time and effort but also minimizes material waste, contributing to overall cost-effectiveness.II. Benefits for the Packaging Industry:The introduction of the Pp Lamination Machine has brought several tangible benefits to the packaging industry, addressing key concerns and challenges faced by businesses:1. Enhanced Product Protection: The PP film applied by the machine acts as a protective layer, shielding packaged products from environmental factors such as humidity, dust, and light. By eliminating potential damage or spoilage, businesses can maintain product quality and reduce the risk of returns or customer dissatisfaction.2. Increased Visual Appeal: The Pp Lamination Machine significantly enhances the aesthetics of packaging materials, making them more visually appealing to consumers. Vibrant colors, glossy finishes, and excellent print adhesion contribute to an overall attractive package, resulting in improved brand perception and increased consumer engagement.3. Improved Shelf Life: By utilizing the Pp Lamination Machine to apply a PP film, businesses can extend the shelf life of their products significantly. This durability is especially crucial for industries dealing with perishable or delicate items such as food, pharmaceuticals, and electronics. By ensuring product freshness and integrity, companies can reduce waste and enhance customer satisfaction.4. Sustainability and Cost Savings: The fully automated nature of the Pp Lamination Machine helps minimize material waste, contributing to a more sustainable manufacturing process. Additionally, the machine's ability to deliver consistent lamination results reduces the need for rework, saving both time and costs for businesses in the long run.Conclusion:In conclusion, the introduction of the Pp Lamination Machine has brought a new wave of innovation to the packaging industry. With its advanced technology, precision, and efficiency, this machine is transforming the way packaging materials are manufactured and utilized, benefiting businesses worldwide. From improved product protection and enhanced visual appeal to increased shelf life and sustainability, the Pp Lamination Machine offers an all-in-one solution that sets a new standard for packaging excellence. As the industry continues to evolve, this cutting-edge machine will undoubtedly play a vital role in shaping the future of packaging and manufacturing practices.

Powerful Heavy Machinery: Key Player in the Industry

Hengli Machine, a leading manufacturer in the machinery industry, has recently announced a major breakthrough in their product line. With over 20 years of experience in the industry, Hengli Machine has established itself as a reputable and innovative company, consistently delivering high-quality machinery to meet the ever-evolving needs of their customers.The company's commitment to research and development has led to the creation of a new line of cutting-edge machines that are set to revolutionize the industry. These new machines are designed to improve efficiency, precision, and productivity, ultimately helping businesses to achieve their production goals in a more cost-effective manner.Hengli Machine's dedication to continuous improvement and innovation is reflected in their state-of-the-art manufacturing facility. Equipped with the latest technology and operated by a team of highly skilled professionals, the company is able to produce superior quality machines that meet the highest industry standards.In addition to their advanced manufacturing capabilities, Hengli Machine also places a strong emphasis on customer satisfaction. By providing excellent customer service and support, the company has built long-standing relationships with clients around the world. This customer-centric approach has earned Hengli Machine a reputation for reliability and trustworthiness in the industry.The recent launch of the new product line has generated significant excitement within the industry, with businesses eagerly anticipating the opportunity to incorporate these cutting-edge machines into their operations. The improved efficiency and productivity offered by the new machines are expected to deliver significant cost savings and performance enhancements for businesses across various sectors.In response to the positive reception of their new product line, Hengli Machine's CEO expressed his enthusiasm about the company's continued success and growth. He emphasized the company's ongoing commitment to innovation and the relentless pursuit of excellence in meeting the needs of their customers.As a result of their dedication to quality and innovation, Hengli Machine has received numerous accolades and certifications for their products and services, further solidifying their position as an industry leader. The company's continuous investment in research and development has enabled them to stay at the forefront of the market, offering cutting-edge solutions that address the evolving needs of their customers.Looking ahead, Hengli Machine remains focused on expanding their product offerings and further enhancing their capabilities to cater to a broader range of industries. The company is dedicated to staying ahead of the curve, ensuring that they can continue to deliver innovative and reliable machinery that empowers businesses to succeed in today's competitive market.In conclusion, Hengli Machine's recent announcement regarding their new product line exemplifies the company's unwavering commitment to innovation and excellence. With a strong focus on quality, efficiency, and customer satisfaction, Hengli Machine continues to set the standard for machinery manufacturing, and their new product line is poised to make a significant impact on the industry. As the company looks toward the future, it is clear that Hengli Machine will remain a driving force in the machinery industry, continuously delivering new and advanced solutions that empower businesses to thrive.

Efficient and Reliable Packaging Machines for Industrial Use

Industrial packing machines are essential in the manufacturing industry where packaging is an inevitable process. The unprecedented growth in the manufacturing sector has led to increased demand for high-quality packaging machines. In response to this, a leading company has manufactured and introduced a state-of-the-art industrial packing machine that’s expected to revolutionize the industry.The new industrial packing machine, which we will refer to as the “Packing Machine” in this article, is automated, user-friendly, and efficient. Unlike traditional packaging machines, the Packing Machine is flexible and can handle multiple packaging materials such as plastic, paper, and metal. Its high-speed performance and consistent quality ensure that the manufacturing process is streamlined, and the packaging meets the highest standards.Additionally, the Packing Machine is built with precision materials and comes with automatic systems for predetermined container formats, ensuring that the packaging process is consistent. This feature eliminates the need for workers to adjust the machine manually, reducing the chances of errors and increasing productivity.The company behind the Packing Machine has been in the manufacturing business for over 20 years, specializing in the production of packaging machines for industrial use. With the introduction of the Packing Machine, the company aims to consolidate its position as a market leader in the manufacturing industry.“Over the years, we have witnessed the transformation of the manufacturing industry, and it’s evident that the packaging process is an integral part of the production process,” said the company’s spokesperson. “The launch of the Packing Machine is a testament to our commitment to providing innovative solutions that enhance efficiency, reduce costs, and increase productivity.”The spokesperson added that the company invested a considerable amount of time and resources in the research and development of the Packing Machine, focused on addressing the shortcomings of traditional packaging machines. The result is a durable, low-maintenance machine that’s designed for seamless integration into various manufacturing processes.The Packing Machine is not only efficient, but it’s also environmentally friendly. It incorporates a sustainable design that encourages the recycling of packaging materials, reducing waste and environmental pollution. The machine’s low energy consumption and reduced packaging material wastage also make it a cost-effective solution for manufacturing processes.Despite the challenges posed by the COVID-19 pandemic, the company managed to incorporate safety measures to protect their workers while ensuring that the production of the Packing Machine was not disrupted. The company enforced strict adherence to the health guidelines, including social distancing, wearing face masks, and regular sanitization of surfaces.The Packing Machine has received positive feedback from customers who have already adopted it in their manufacturing processes. They cite the machine’s reliability, efficiency, and affordability as the primary reasons for their satisfaction.One of the customers who recently purchased the Packing Machine, a global food manufacturing company, praised its flexibility, speed, and consistent quality. “We have been using the Packing Machine for a few months now, and it has exceeded our expectations,” said the quality control manager. “It’s an innovative solution that has significantly improved our production process, and we would highly recommend it to anyone looking for an industrial packing machine.”With the launch of the Packing Machine, the company is poised for growth, and it’s expected that many manufacturing companies will adopt it, reducing their costs and improving the quality of their products. Its innovative features, coupled with the company’s reputation for excellence, make it a product that’s bound to change the industrial packing machine market.In conclusion, the introduction of the Packing Machine is a significant milestone in the manufacturing industry. Its innovative features, environmentally friendly design, and cost-effectiveness are some of the reasons why it’s a preferred choice for many companies. With the company’s reputation for excellence and commitment to providing innovative solutions, the Packing Machine is poised to become a game-changer in the industrial packing machine market.

Efficient and Affordable Woven Fabric Bag Making Machine Unveiled in Latest News

Title: Innovations in Woven Fabric Bag Making Machine Speed Up Production ProcessIntroduction:In recent years, technological advancements have significantly transformed the manufacturing industry, making operations more efficient and productive. The textile sector, in particular, has witnessed remarkable progress with the introduction of woven fabric bag making machines. These machines, utilizing cutting-edge technology, have revolutionized the production process, reducing labor costs and increasing output. A leading manufacturer in the industry, {}. targets to enhance the manufacturing landscape with their state-of-the-art woven fabric bag making machines.Accelerating Production With Advanced Features:The {} woven fabric bag making machinery incorporates several innovative features designed to optimize productivity and improve overall efficiency. This cutting-edge equipment streamlines the bag production process, minimizing human error and reducing the time required for completion. The machine's high-speed operation ensures enhanced output, catering to the growing demand for woven fabric bags across various industries.One of the notable features of the {} machine is its automatic feeding system. By utilizing this system, the machine efficiently feeds the woven fabric into the production line, ensuring a smooth workflow and eliminating the need for manual input. This automated process significantly reduces labor costs while enhancing precision and accuracy.Additionally, the {} machine boasts advanced cutting mechanisms, enabling precise and clean cuts, even with heavy-duty materials. The ability to handle different fabric thicknesses allows manufacturers to create a wide range of bags suitable for various purposes. This versatility is further enhanced by the machinery's customization options, enabling manufacturers to produce bags of different shapes, sizes, and designs to cater to specific customer needs.Enhanced Durability and Sustainability:The {} woven fabric bag making machine emphasizes durability and sustainability in its design. By utilizing high-quality materials and components, the machine ensures a long service life, reducing maintenance costs for manufacturers. Furthermore, the use of energy-efficient technology in the machine's operation minimizes environmental impact and lowers energy consumption.The company understands the global push towards sustainability and aims to support the transition by manufacturing eco-friendly woven fabric bag making machines. By employing recycled materials and minimizing waste during the production process, the {} machine aligns with the growing demand for environmentally conscious manufacturing practices.Promoting Economic Growth and Job Creation:As companies across different industries recognize the benefits of woven fabric bags, the demand for reliable and efficient bag-making machinery continues to rise. The {} woven fabric bag making machine addresses the market demands and creates new opportunities for economic growth and job creation.By streamlining the bag production process, the machine enables manufacturers to meet market demands quickly, resulting in increased profitability. Furthermore, the decrease in manual labor requirements allows manufacturers to reallocate resources to other areas of production, stimulating innovation and overall industrial growth.Conclusion:In conclusion, the revolutionary {} woven fabric bag making machine presents a game-changing solution for the manufacturing industry. With its advanced features, enhanced durability, sustainability-focused design, and ability to boost productivity, this machinery contributes to economic growth, job creation, and a more sustainable manufacturing landscape. As more companies adopt these innovative bag-making machines, the industry will witness a significant shift towards increased efficiency and profitability.

High Quality PP Woven Sack Printing Machine offers Efficient Printing Solutions

PP Woven Sack Printing Machine: The Game-Changer in Packaging IndustryThe rise of global trade has given birth to the packaging industry. The need to transport goods from one place to another in a secure and efficient way has led to the development of various packaging materials such as corrugated boxes, plastic bags, and woven sacks. Among these materials, woven sacks have gained immense popularity due to their strength and durability.Woven sacks are widely used to package goods such as cement, fertilizer, and animal feed. They are made from polypropylene (PP) material, which is known for its thermal stability, chemical resistance, and moisture resistance. The demand for woven sacks has been increasing due to their eco-friendliness, convenience, and cost-effectiveness.To meet the growing demand for woven sacks, many packaging companies have invested in PP Woven Sack Printing Machines. These machines have revolutionized the manufacturing process of woven sacks by providing high-quality print on them. The PP Woven Sack Printing Machine uses a rotogravure printing process, which involves the use of a cylinder covered in tiny cells to transfer ink onto the woven sack.The PP Woven Sack Printing Machine offers a wide range of benefits to the packaging industry. It provides high-speed printing with a production capacity of up to 120 bags per minute. It also offers customization options, including the ability to print multiple colors, graphics, and logos on the woven sacks. This allows companies to brand their products effectively and distinguish themselves from their competitors.Moreover, the PP Woven Sack Printing Machine saves time and reduces labor costs. It eliminates the need for manual printing, which is a time-consuming and labor-intensive process. The machine also ensures accuracy and consistency in the printing process, resulting in a uniform and professional-looking product.One company that has invested in PP Woven Sack Printing Machines is {} (remove brand name). The company, founded in {}, has established itself as a leading manufacturer and exporter of PP woven sacks. Its state-of-the-art manufacturing facility is equipped with the latest machinery, including PP Woven Sack Printing Machines.The company's PP Woven Sack Printing Machines are capable of producing high-quality prints that are resistant to water, chemicals, and UV radiation. They are also energy-efficient, using less electricity than traditional printing methods. The machines have contributed to the company's success by providing customers with high-quality products that meet their specific requirements.In addition to PP Woven Sack Printing Machines, {} (remove brand name) also offers a wide range of packaging solutions, including woven sacks, laminated bags, and bulk bags. Its products are widely used in the packaging of agricultural, industrial, and construction products.{}(remove brand name) is committed to providing eco-friendly packaging solutions that meet international standards. The company's woven sacks are 100% recyclable and biodegradable, making them an environmentally responsible choice for packaging goods. The company also follows sustainable practices in its manufacturing processes, such as using renewable energy sources and reducing waste.In conclusion, the PP Woven Sack Printing Machine has emerged as a game-changer in the packaging industry, providing high-quality prints on woven sacks and reducing labor costs. Companies like {} (remove brand name) have invested in these machines to meet the growing demand for woven sacks and provide their customers with high-quality products. As the demand for eco-friendly packaging solutions continues to rise, the PP Woven Sack Printing Machine is expected to play a crucial role in the future of the packaging industry.

Cutting-Edge Fully Automatic Screen Printing Machine Takes the Industry by Storm

Fully Automatic Screen Printing Machine Revolutionizes Production Process[City, Date] - In a major breakthrough for the manufacturing industry, a cutting-edge fully automatic screen printing machine has been unveiled, promising to revolutionize the production process for companies worldwide. Developed by a leading technology company, this innovative machine has the potential to significantly boost speed, quality, and efficiency in the printing industry.With its advanced features and state-of-the-art technology, this fully automatic screen printing machine is set to redefine the way companies handle their printing needs. Gone are the days of manual labor and long production times. This machine combines speed, precision, and reliability, ensuring that businesses can meet the demands of their customers in a more timely and cost-effective manner.The most remarkable feature of this machine is its ability to automate the entire printing process. From preparing the design to the final output, the machine seamlessly carries out all the necessary steps with minimal human intervention. This not only reduces the chances of human error but also increases the productivity of the entire production line.Another notable advantage of this machine is its incredible speed. With a high printing rate of [insert speed], companies can now complete large printing orders in a fraction of the time it used to take. This feature is particularly valuable for businesses in industries where meeting tight deadlines is crucial.Furthermore, the fully automatic screen printing machine guarantees exceptional print quality. Its precision-driven mechanism ensures that every detail of the design is accurately reproduced on the chosen medium. Whether it's textiles, ceramics, or plastics, this machine's superior technology ensures vibrant colors and sharp images that are sure to impress even the most discerning clients.In addition to its technical advancements, this fully automatic screen printing machine also boasts a user-friendly interface. Designed with ease-of-use in mind, it allows operators to navigate through its various functions effortlessly. Its intuitive controls ensure that even those with minimal experience can quickly familiarize themselves with the machine's operation.The benefits of this fully automatic screen printing machine extend beyond its technical specifications. With its integration into production processes, companies can significantly reduce overhead costs. Increased automation leads to savings in labor expenses while the machine's efficiency ensures minimal material wastage. As a result, businesses can enjoy higher profit margins and maintain a competitive edge in their respective markets."Integrating the fully automatic screen printing machine into our production process was a game-changer for our business," said [name], CEO of [company name]. "We were able to reduce our production time by half, all while maintaining excellent quality. This technological innovation has allowed us to take on larger orders and expand our client base with ease."The introduction of this fully automatic screen printing machine has not only transformed companies' production processes but has also provided a much-needed stimulus to the manufacturing industry. As businesses continue to adopt this groundbreaking technology, it is anticipated that the demand for fully automatic screen printing machines will soar, driving industry growth and technological innovation in the coming years.The future of screen printing is undoubtedly bright with this fully automatic screen printing machine at the forefront. Its ability to seamlessly integrate into existing production lines, increase output quality and quantity, and reduce costs make it an indispensable tool for any printing business looking to thrive in today's competitive market.About [Company]:[Company] is a leading technology company at the forefront of innovative solutions for the printing industry. With a commitment to providing cutting-edge machinery and technology, [Company] has gained recognition for its ability to meet the evolving needs of businesses worldwide. Through continuous research and development, they aim to revolutionize the printing industry and empower companies to achieve their production goals efficiently and effortlessly.

How to make paper bags with a machine at home

Title: Revolutionizing Paper Bag Production: Innovative Machine Aims to Banish Plastic BagsIntroduction:In response to the growing concern over plastic pollution and its detrimental effects on the environment, a pioneering company has developed a groundbreaking machine that aims to revolutionize the production of paper bags. This innovative technology, which we will refer to as the Paper Bag Making Machine (PBMM), is poised to address the pressing need for eco-friendly alternatives to single-use plastic bags. The PBMM holds immense potential to replace plastic bags and bring about a significant shift towards sustainability and a greener future.Unveiling Innovative Features:The PBMM boasts several unique features that set it apart from traditional paper bag-making machines. This cutting-edge technology leverages advanced automation systems, ensuring precise and efficient bag production. Equipped with sophisticated sensors, the PBMM can accurately measure and regulate the amount of paper required for each bag while minimizing wastage. Furthermore, its high-speed capabilities allow for increased productivity, enabling the mass production of paper bags to meet consumer demands and reduce plastic bag usage.The paper bag production process involves the raw material being fed into the machine, which then precisely folds, glues, and cuts the paper to create the bags. This entire process is automated, resulting in consistent quality and reduced dependency on manual labor. The PBMM can accommodate various sizes and types of bags, catering to diverse usage requirements, including shopping bags, food packaging, and more.Advancing Sustainability:The elimination of single-use plastic bags is a significant step forward in curbing plastic pollution and minimizing the adverse ecological impact. As plastic bags take centuries to decompose, they contribute to land and water pollution, endangering wildlife and ecosystems. The PBMM aims to tackle this prevalent issue head-on by producing biodegradable and recyclable paper bags, which are far more environmentally friendly.With its remarkable production capacity, the PBMM has the potential to significantly decrease the demand for plastic bags globally. By promoting the use of eco-friendly alternatives, including paper bags, it can lead to a marked reduction in plastic waste while encouraging a behavioral shift among consumers towards more sustainable choices.Economic Benefits and Market Opportunities:The development of the PBMM not only addresses the pressing environmental concern of plastic pollution but also opens new avenues for economic growth and market expansion. By offering an alternative to plastic bags, businesses can benefit from increased consumer appeal and brand value, as more customers actively seek eco-friendly options.Additionally, the PBMM presents employment opportunities within the manufacturing sector, as the demand for paper bags rises. The setup, operation, and maintenance of this automated machine require skilled personnel, which contributes to local job creation and economic development.Collaborating for Change:To maximize the impact of this innovative technology, the company behind the PBMM is actively seeking collaborations with governments, corporations, and non-profit organizations. By fostering partnerships, they aim to garner support and drive large-scale societal change towards a plastic-free future. Such collaborations can pave the way for policy reforms, public awareness campaigns, and financial incentives, further encouraging the adoption of paper bags and the phasing out of plastic alternatives.Conclusion:The introduction of the revolutionary Paper Bag Making Machine (PBMM) signifies a significant step forward in the fight against plastic pollution. With its innovative features, production efficiency, and focus on sustainability, the PBMM offers a compelling solution to address the global issue of single-use plastic bags. By replacing plastic bags with biodegradable and recyclable paper bags, this technology promises to create a greener, more sustainable future for generations to come. Through crucial collaborations and joint efforts, we can work towards a world where plastic bags are no longer the norm, but an obsolete relic of a bygone era.

Enhancing Efficiency: Discover the Benefits of Industrial Packing Machines

Industrial Packing Machine Launches Advanced Packaging Solutions Industrial Packing Machine, a leading provider of innovative packaging machinery, has unveiled its latest range of advanced packaging solutions. The company, with decades of expertise in the industry, aims to revolutionize the packaging process for businesses across various sectors.As a pioneer in the field, Industrial Packing Machine has always remained committed to delivering top-quality and reliable packaging solutions. The company's team of experienced engineers and designers strive to develop cutting-edge systems that streamline the packaging process while ensuring maximum efficiency and durability.The newly launched range of packing machines incorporates state-of-the-art technology and features designed to meet the evolving needs of diverse industries. These advanced solutions offer businesses improved speed, accuracy, and reliability, ultimately translating into enhanced productivity and profitability.One of the highlights of the new range is the fully automated packing system. This intelligent packaging solution minimizes human intervention, reducing the risk of errors and ensuring consistent and precise packaging. Equipped with smart sensors and high-speed motors, the automated system can handle a wide variety of products with different shapes and sizes. Additionally, it enables the integration and synchronization of multiple machines, streamlining the packaging line for seamless production.Industrial Packing Machine's commitment to customization is evident in its launch of customized packing solutions. The company understands that each business has unique packaging requirements, and thus offers tailored solutions to cater to those needs. From custom-shaped packaging to specific labeling and marking requirements, Industrial Packing Machine's engineers work closely with clients to design and develop solutions that address their individual packaging challenges.To further enhance the efficiency and performance of the packaging process, Industrial Packing Machine has introduced its innovative quality control technologies. The integrated inspection systems ensure that each package meets the desired standards and specifications. These automated quality control systems detect and eliminate any defects or inconsistencies, eliminating the possibility of faulty products reaching the market. This feature plays a crucial role in maintaining brand reputation and customer satisfaction.Environmental considerations have become increasingly important in the packaging industry in recent years. In response to this emerging trend, Industrial Packing Machine has implemented eco-friendly features in its new range. The machines are designed to minimize material wastage and optimize energy consumption, contributing to a more sustainable packaging process. By investing in these advanced solutions, businesses can align their operations with environmental responsibility and demonstrate their commitment to sustainability.Industrial Packing Machine's dedication to customer satisfaction extends beyond the development of cutting-edge machinery. The company provides comprehensive after-sales support to ensure the optimal performance and longevity of its products. Skilled technicians offer installation, training, and maintenance services, ensuring that clients can operate their packing machines efficiently and effectively.With its latest range of advanced packaging solutions, Industrial Packing Machine aims to set a new benchmark in the industry. The company's commitment to innovation, customization, and sustainability positions it as an ideal partner for businesses looking to optimize their packaging processes. As the market continues to evolve, Industrial Packing Machine remains at the forefront by consistently delivering advanced and reliable solutions that meet the diverse needs of its clients.