New Woven Sack Plant to be Established in Region

By:Admin

With a history of over [X] years, Woven Sack Plant has continually sought to innovate and upgrade its manufacturing capabilities, in line with market demand and customer requirements. The new facility represents a significant milestone in the company's journey, showcasing a commitment to excellence and a dedication to delivering top-quality products to its clients.

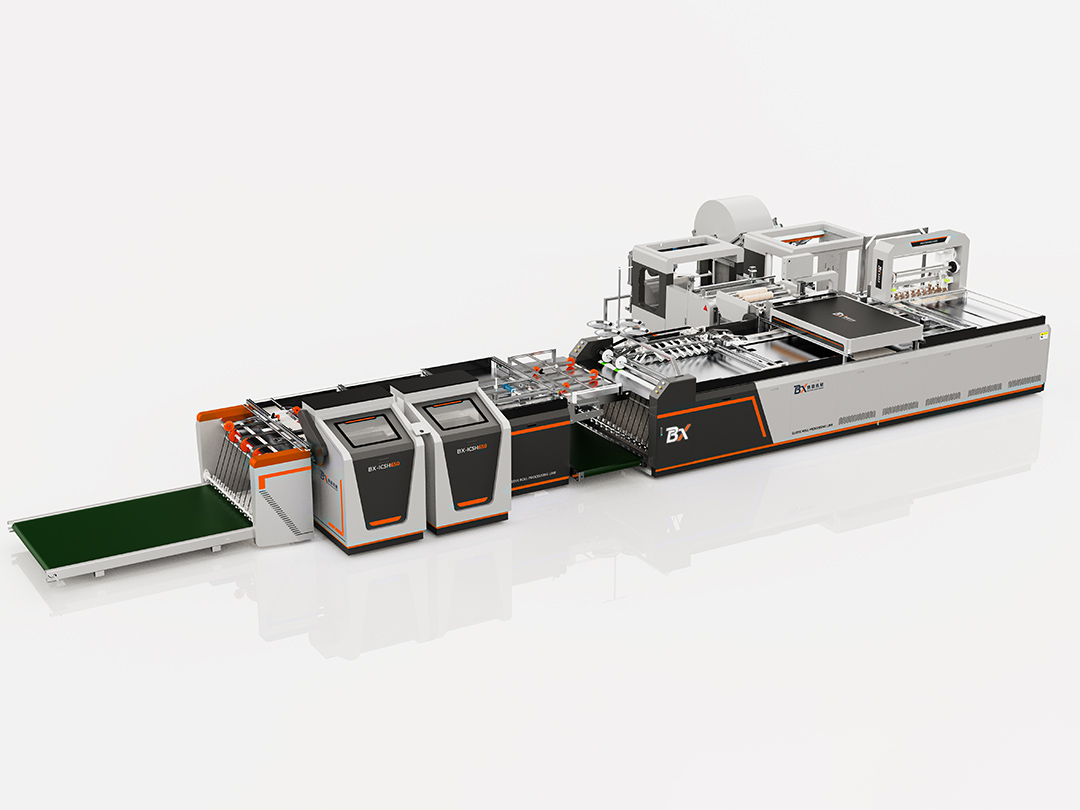

The plant's production line is equipped with the latest machinery and technology, enabling Woven Sack Plant to produce a diverse range of woven polypropylene bags, ensuring flexibility and adaptability to meet customer specifications. The facility's high capacity also means that the company can cater to large orders, providing a solution for businesses with high-volume packaging needs.

In addition to the production capabilities, the plant is also designed with a focus on sustainability and eco-conscious manufacturing practices. Woven Sack Plant has implemented measures to minimize waste, reduce energy consumption, and maximize the use of recyclable materials in its production processes. The company is proud to contribute to environmental preservation and sustainable manufacturing, aligning with global efforts to build a more sustainable future.

Furthermore, Woven Sack Plant's commitment to quality is evident in the stringent quality control measures implemented at the new facility. Every woven polypropylene bag produced undergoes thorough inspection and testing to ensure durability, strength, and reliability. This dedication to quality assurance is a testament to the company's pledge to deliver products that meet the highest industry standards.

The launch of the new production facility has also created numerous employment opportunities within the local community, further demonstrating Woven Sack Plant's commitment to supporting economic growth and development in the region. The company's investment in the facility reflects its long-term vision and commitment to contributing to the prosperity of the communities in which it operates.

As part of its customer-centric approach, Woven Sack Plant also offers customization options for its woven polypropylene bags, allowing clients to personalize their packaging solutions to suit their branding and product requirements. This level of flexibility is made possible through the plant's advanced production capabilities and the company's dedication to fulfilling unique customer needs.

Woven Sack Plant's new facility represents a significant advancement in the company's manufacturing capabilities, solidifying its position as a leading provider of woven polypropylene packaging solutions. The plant's modern infrastructure, sustainable practices, and commitment to quality and customization all contribute to Woven Sack Plant's ability to meet the evolving needs of its customers in various industries, including agriculture, construction, and retail.

With a strong foundation built on experience, expertise, and a continuous drive for improvement, Woven Sack Plant is poised to continue its growth trajectory and maintain its status as a preferred partner for businesses seeking reliable and innovative packaging solutions. The unveiling of the new production facility marks a pivotal moment for the company, reinforcing its dedication to excellence and its readiness to meet the challenges of an ever-changing market.

Company News & Blog

High-Quality Suitcase Making Machine for Efficient Production

{Company Name} Unveils State-of-the-Art Suitcase Making Machine In a bid to revolutionize the luggage manufacturing industry, {Company Name}, a leading manufacturer of industrial machinery, has unveiled its latest innovation - a cutting-edge suitcase making machine. This groundbreaking technology is set to streamline the production process, increase efficiency, and elevate the quality of suitcases being produced.The newly developed suitcase making machine is a result of extensive research and development efforts by {Company Name}'s team of expert engineers and designers. Leveraging advanced automation and robotics technology, this state-of-the-art machine is capable of producing a wide range of suitcases with precision and consistency.One of the key features of the machine is its ability to handle various materials, including ABS, polycarbonate, and aluminum. This flexibility allows manufacturers to create suitcases of different styles, sizes, and designs to cater to the diverse needs of consumers. Additionally, the machine is equipped with cutting-edge molding and shaping mechanisms to ensure that the finished products meet the highest standards of quality and durability.Furthermore, the machine boasts an intuitive and user-friendly interface, making it easy for operators to control and monitor the production process. With built-in sensors and intelligent systems, the machine is able to detect and rectify any potential issues, thereby minimizing downtime and maximizing productivity.The introduction of this advanced suitcase making machine is expected to bring about several benefits for manufacturers in the luggage industry. With its high-speed production capabilities, the machine can significantly increase output, allowing companies to meet growing demands and capitalize on market opportunities. Moreover, its precision engineering ensures that each suitcase is crafted with utmost accuracy, resulting in a consistent and superior end product.From a cost perspective, the machine's efficiency and automation can lead to reduced labor costs and material wastage, ultimately translating into higher profit margins for manufacturers. Additionally, its ability to produce high-quality suitcases at a faster rate can propel companies ahead of competitors, giving them a significant edge in the market.{Company Name} has a long-standing reputation for developing cutting-edge industrial machinery, and the introduction of the suitcase making machine further solidifies its position as an industry leader. With a commitment to innovation and excellence, the company continues to push the boundaries of technology to empower businesses and drive progress across various sectors.In addition to its technological prowess, {Company Name} also prides itself on providing exceptional customer support and service. From installation and training to maintenance and technical assistance, the company offers comprehensive solutions to ensure that its clients maximize the value and performance of its machines.The unveiling of the suitcase making machine represents a significant milestone for {Company Name}, signaling its dedication to advancing the manufacturing landscape. By introducing this innovative technology, the company aims to propel the luggage industry into a new era of efficiency, quality, and competitiveness.As the global demand for suitcases continues to grow, manufacturers are under increasing pressure to deliver products that embody both style and substance. With {Company Name}'s new suitcase making machine, businesses now have the means to rise to this challenge and set new standards for excellence in luggage production.

Efficient and Reliable Bag Cutting Machine for PP Bags

Pp Bag Cutting Machine revolutionizes the packaging industryThe {Company Name} has introduced a groundbreaking Pp Bag Cutting Machine that is set to revolutionize the packaging industry. This innovative machine is designed to cut, seal, and shape polypropylene (PP) bags with precision and speed, making it ideal for use in a wide range of industries including agriculture, food processing, and manufacturing.The Pp Bag Cutting Machine features advanced technology and a user-friendly interface, allowing operators to easily program the machine to cut bags to their desired size and shape. The machine can handle a variety of bag sizes and thicknesses, making it a versatile solution for diverse packaging needs. Its high-speed cutting and sealing capabilities also ensure maximum efficiency and productivity, helping businesses to save time and resources in their packaging processes.One of the key features of this cutting machine is its precision cutting technology, which ensures clean and accurate cuts on every bag. This not only enhances the overall appearance of the packaged products but also minimizes the risk of product spillage or contamination during transportation and storage. In addition, the machine's automatic sealing function creates secure and tamper-evident seals on the bags, providing added protection for the contents inside.Furthermore, the Pp Bag Cutting Machine is equipped with safety features and built-in sensors to prevent accidents and ensure smooth operation. Its durable construction and low maintenance requirements make it a reliable and cost-effective investment for businesses of all sizes. With its ability to streamline the packaging process and improve the quality of packaged products, this machine is set to become an essential asset for companies looking to enhance their packaging operations.{Company Name} is a leading provider of innovative packaging solutions, with a strong focus on quality, reliability, and customer satisfaction. With a commitment to continuous improvement and technological advancements, the company has earned a reputation for delivering cutting-edge products that meet the evolving needs of the packaging industry.The introduction of the Pp Bag Cutting Machine reaffirms {Company Name}'s dedication to providing innovative solutions that help businesses optimize their packaging processes and achieve greater efficiency. By leveraging advanced technology and industry expertise, the company continues to set new standards in the packaging industry and empower its customers to stay ahead of the competition.As businesses around the world seek to enhance their packaging operations and meet the demands of an increasingly competitive market, the Pp Bag Cutting Machine from {Company Name} offers a game-changing solution that delivers precision, reliability, and efficiency. Its ability to streamline the packaging process and improve the overall quality of packaged products makes it a valuable asset for businesses across diverse industries.In conclusion, the introduction of the Pp Bag Cutting Machine by {Company Name} marks a significant milestone in the packaging industry. With its advanced technology, user-friendly design, and versatility, this innovative machine is set to transform the way businesses approach packaging, offering a combination of precision, efficiency, and reliability that is unmatched in the market. As companies look to optimize their packaging processes and stay ahead of the competition, the Pp Bag Cutting Machine presents a game-changing solution that sets new standards for quality and performance.

Top Non Woven Bag Making Machine for Efficient Production

[Company Introduction]With a commitment to innovation and sustainability, [Company Name] is a leading manufacturer of non woven bag making machines. Our company has been dedicated to providing high-quality and efficient machinery for non woven bag production, contributing to the global movement towards eco-friendly and reusable packaging solutions.[Company Name] has a state-of-the-art manufacturing facility equipped with advanced technology and a team of skilled engineers and technicians. Our machines are designed to meet the growing demand for non woven bags in various industries, including retail, e-commerce, and agriculture. We take pride in our ability to deliver reliable and cost-effective solutions that help businesses reduce their environmental impact while improving their packaging capabilities.[News Content]The non woven bag industry is experiencing a significant surge in demand as businesses and consumers alike continue to prioritize sustainability and environmental consciousness. In response to this trend, [Company Name] has introduced a new, cutting-edge non woven bag making machine that promises to revolutionize the production process and meet the increasing need for eco-friendly packaging solutions.The latest addition to [Company Name]'s lineup of non woven bag making machines is a result of extensive research and development efforts, aimed at enhancing efficiency, productivity, and sustainability in bag manufacturing. This advanced machine integrates state-of-the-art technology to deliver superior performance and versatility, making it an ideal choice for businesses seeking to adopt sustainable packaging practices.One of the key features of this new non woven bag making machine is its ability to produce a wide range of bag sizes and designs, catering to the diverse needs of different industries. Whether it's a standard grocery bag, a customized promotional tote, or a specialized agricultural sack, this machine offers customizable options to meet the specific requirements of our customers.In addition, [Company Name]'s new non woven bag making machine is designed for seamless operation, with minimal downtime and low maintenance requirements. This ensures that businesses can maximize their production output while minimizing costs and resource consumption, aligning with the principles of sustainable manufacturing and waste reduction.Furthermore, the machine is equipped with advanced control systems and automation features, allowing for precise and consistent bag production. This not only improves the overall quality of the non woven bags but also enhances the efficiency of the manufacturing process, reducing the need for manual intervention and increasing the overall output.As sustainability remains at the core of [Company Name]'s mission, the new non woven bag making machine is engineered to minimize energy consumption and material waste. By optimizing the use of resources and streamlining the production process, this machine enables businesses to create eco-friendly and cost-effective non woven bags, contributing to the global effort to reduce single-use plastic and promote environmentally responsible packaging solutions.The introduction of [Company Name]'s latest non woven bag making machine reflects our ongoing commitment to innovation, sustainability, and customer satisfaction. With this new addition to our product lineup, we aim to empower businesses with the tools and technology they need to embrace eco-friendly packaging practices and meet the growing demand for non woven bags across various industries.In conclusion, [Company Name]'s new non woven bag making machine represents a significant advancement in the field of sustainable packaging solutions, offering businesses the opportunity to enhance their production capabilities and contribute to a greener, more environmentally conscious future. As the demand for non woven bags continues to rise, [Company Name] remains dedicated to providing cutting-edge machinery and support to help businesses thrive in a rapidly evolving market.

Innovative Lamination Machine for Woven Bags Boosts Efficiency and Durability

Woven Bag Lamination Machine - An Innovative Solution for Heavy-Duty PackagingIn today's global economy, there is a growing demand for high-quality, durable packaging solutions. Whether it's for shipping goods across long distances or for storing agricultural produce, packaging plays a critical role in protecting products from damage and extending their shelf life. In recent years, woven bags have emerged as a popular choice for packaging applications due to their superior strength and durability. However, the performance of these bags can be further enhanced with the use of lamination technology. This is where the Woven Bag Lamination Machine comes into play.The Woven Bag Lamination Machine is a state-of-the-art piece of equipment designed to add a layer of protective film to woven bags, thereby enhancing their strength, moisture resistance, and printing quality. This innovative solution is particularly useful for heavy-duty packaging applications that require extra strength and durability. The lamination film is typically made of polypropylene (PP) or polyethylene (PE), both of which are widely used in the packaging industry for their excellent mechanical, physical, and chemical properties.One of the key benefits of using the Woven Bag Lamination Machine is that it enables manufacturers to customize the bags according to their specific requirements. By adjusting the thickness, color, and printing quality of the lamination film, manufacturers can create bags that are tailored to their customers' needs. This is especially important in industries such as agriculture and construction, where the bags may be exposed to harsh outdoor conditions and need to withstand rough handling.The Woven Bag Lamination Machine is also a cost-effective solution for manufacturers. By adding a layer of lamination to woven bags, manufacturers can extend the lifespan of the bags, reduce the risk of damage during transit, and ultimately save money on replacements and returns. Additionally, the machine is designed for high-speed operation, which means that manufacturers can produce large quantities of quality bags in a short amount of time.One notable manufacturer of Woven Bag Lamination Machines is the company {}, which has been in the business of producing packaging machinery since {}. The company's Woven Bag Lamination Machine is highly regarded by customers around the world for its advanced features and reliable performance.The machine is equipped with a top-quality unwinder, tension control system, and heat sealing technology, which allow for precise and consistent lamination results. The machine can laminate bags with a width of up to {}mm and a speed of up to {} meters per minute. It also has a user-friendly interface and can be operated by a single person, making it ideal for small to medium-sized businesses.In addition to the Woven Bag Lamination Machine, {} offers a wide range of other packaging machinery, including printing machines, cutting machines, and bag making machines. The company's products are known for their high quality, durability, and affordability.Overall, the Woven Bag Lamination Machine is a game-changer in the packaging industry. Its ability to enhance the performance of woven bags and improve their customization options makes it a valuable addition to any manufacturer's arsenal. For businesses that require heavy-duty packaging solutions, investing in a Woven Bag Lamination Machine can lead to significant cost savings and improved customer satisfaction. With companies like {} leading the way in packaging machinery innovation, the future of packaging looks bright.

Cutting-edge PE Machine Technology Could Revolutionize Manufacturing

PE Machine, a leading provider of high-quality machinery and equipment, is making waves in the industrial equipment sector with its innovative and cutting-edge products. The company has established itself as a prominent player in the industry, with a reputation for delivering top-of-the-line machinery that meets the diverse needs of its customers.With a wide range of products and solutions, PE Machine has become a trusted name in the manufacturing and industrial sector. The company is known for its commitment to quality, reliability, and customer satisfaction, making it a preferred choice for businesses looking for high-performance machinery.Founded with the vision of revolutionizing the industrial equipment industry, PE Machine has invested heavily in research and development to create products that are at the forefront of technological advancement. The company's state-of-the-art manufacturing facilities and adherence to stringent quality control measures ensure that every product that bears the PE Machine name is of the highest standard.One of the key factors that set PE Machine apart from its competitors is its dedication to innovation. The company is constantly seeking to push the boundaries of what is possible in industrial equipment, and its team of engineers and technicians work tirelessly to develop new and improved products that cater to the evolving needs of the industry. This commitment to innovation has allowed PE Machine to stay ahead of the curve and maintain its position as a market leader.PE Machine's product portfolio encompasses a wide range of machinery, including {types of machinery}, making it a one-stop shop for businesses looking to enhance their manufacturing capabilities. Whether it's precision engineering, heavy-duty industrial equipment, or cutting-edge automation solutions, PE Machine has the expertise and resources to deliver products that meet the highest standards of performance and reliability.In addition to its impressive product range, PE Machine also offers comprehensive customer support and after-sales service. The company's team of experienced professionals is always on hand to provide technical support, maintenance, and troubleshooting services, ensuring that customers can maximize the performance and lifespan of their PE Machine equipment.As part of its commitment to sustainability and environmental responsibility, PE Machine has also taken steps to ensure that its manufacturing processes are as eco-friendly as possible. The company adheres to stringent environmental regulations and is constantly exploring ways to reduce its carbon footprint and minimize the impact of its operations on the planet.With a strong focus on continuous improvement and an unwavering dedication to customer satisfaction, PE Machine has solidified its position as a leading provider of industrial machinery and equipment. The company's commitment to quality, innovation, and reliability has earned it the trust and loyalty of customers around the world, and its products are widely recognized for their performance and durability.As the industrial equipment industry continues to evolve, PE Machine remains at the forefront, driving innovation and setting new standards for excellence. With its extensive product range, unyielding commitment to quality, and dedication to customer satisfaction, PE Machine is well-positioned to continue its success and make a lasting impact in the industry for years to come.

Industry Leaders Announce Major Advancements in Machine Technology

Hengli Machinery, a leading company in the field of manufacturing and designing high-quality industrial machinery, has recently made significant advancements in their product line. The company, which has been in operation for over 20 years, has continually demonstrated a commitment to innovation and excellence in the industry.The recent developments at Hengli Machinery have focused on enhancing the performance and efficiency of their machines. One of the key areas of improvement has been in the development of advanced automation and control systems for their equipment. This has allowed for greater precision and accuracy in the manufacturing process, ultimately resulting in higher quality products for their customers.In addition to advancements in automation, Hengli Machinery has also focused on improving the energy efficiency of their machines. By incorporating new technologies and materials, the company has been able to reduce energy consumption without compromising on performance. This not only benefits their customers in terms of cost savings, but also aligns with Hengli Machinery’s commitment to sustainability and environmental responsibility.Another area of focus for Hengli Machinery has been in the development of new product lines to meet the evolving needs of their customers. By staying abreast of industry trends and customer feedback, the company has been able to introduce a range of innovative machines that offer improved functionality and versatility. This has not only expanded their market reach, but also solidified their position as a leader in the industry.One of the most notable new products to come from Hengli Machinery is their latest series of CNC machining centers. These state-of-the-art machines have been designed to provide unmatched precision and speed, making them ideal for a wide range of machining applications. The CNC machining centers have already received positive feedback from early adopters, with many praising the machines for their reliability and performance.Despite the challenges posed by the global pandemic, Hengli Machinery has remained resilient and dedicated to meeting the needs of their customers. The company has implemented strict health and safety protocols to ensure the well-being of their employees, while also working diligently to avoid disruptions to their production and supply chain. As a result, they have been able to maintain a steady flow of high-quality machines to their customers around the world.Looking ahead, Hengli Machinery is poised to continue their trajectory of growth and innovation. With a strong focus on research and development, the company is committed to staying at the forefront of technological advancements in the industry. This includes exploring new materials, manufacturing processes, and design concepts to further enhance the performance and reliability of their machines.In conclusion, the recent advancements at Hengli Machinery underscore the company’s dedication to excellence and innovation. By focusing on key areas such as automation, energy efficiency, and new product development, the company has demonstrated their commitment to meeting the evolving needs of their customers. With a strong track record and a clear vision for the future, Hengli Machinery is well-positioned to continue leading the way in the field of industrial machinery.

Innovative Bag Machine Technology Takes Packaging to the Next Level

Bag-making machine has recently been launched by a leading packaging company, revolutionizing the packaging industry with its advanced technology and efficient production capabilities.The Bag-making machine is the latest addition to the company's extensive range of packaging solutions, offering a versatile and high-speed production of various types of bags. This cutting-edge machine is designed to meet the increasing demand for flexible and customizable packaging options in the market.With its state-of-the-art technology, the Bag-making machine is capable of producing a wide range of bag types, including flat bags, gusseted bags, and side-sealed bags. It can handle a variety of materials, such as polyethylene, polypropylene, and laminates, making it suitable for a diverse range of industries, including food and beverage, pharmaceuticals, and consumer goods.One of the key features of the Bag-making machine is its high-speed production capabilities, which significantly increase the efficiency and productivity of the packaging process. This allows businesses to meet tight deadlines and fulfill the increasing demand for packaging products in a timely manner.In addition to its speed, the Bag-making machine also offers exceptional precision and accuracy in bag production, ensuring consistent quality and reliability in every batch. This is essential for businesses that prioritize product integrity and customer satisfaction.The Bag-making machine is also equipped with advanced control systems, allowing for easy operation and adjustment of production parameters. This user-friendly interface makes it convenient for operators to set up the machine for different bag types and sizes, without the need for extensive training or technical expertise.Furthermore, the Bag-making machine is designed with efficiency in mind, minimizing energy consumption and waste generation during production. This aligns with the company's commitment to sustainability and environmental responsibility, offering businesses an eco-friendly packaging solution.As a leading packaging company, the introduction of the Bag-making machine further strengthens the company's position as an innovative and reliable provider of packaging solutions. With a focus on continuous research and development, the company is committed to staying ahead of market trends and technological advancements, providing its customers with cutting-edge products that meet their evolving needs.The Bag-making machine is the result of extensive research and engineering efforts, aimed at delivering a high-performance packaging solution that sets new standards in the industry. It represents the company's dedication to delivering value-driven and future-proof solutions that help businesses thrive in a competitive market.With its advanced technology, high-speed production capabilities, and user-friendly design, the Bag-making machine is set to redefine the packaging industry and empower businesses to achieve their packaging goals with efficiency and precision. As the demand for flexible and customizable packaging solutions continues to grow, the Bag-making machine emerges as a game-changing innovation that sets the benchmark for packaging excellence.

Top-Rated Bag Making Machine Unveiled: A Game Changer for Sack Production

Sack Bag Making Machine Revolutionizes Packaging IndustryIn this fast-paced world, the demand for efficient and innovative packaging solutions is on the rise. Packaging plays a crucial role in preserving the quality of various products, and businesses are constantly exploring ways to enhance their packaging processes. One such groundbreaking technology that is transforming the packaging industry is the Sack Bag Making Machine.The Sack Bag Making Machine, developed by an industry-leading company (brand name removed), is a cutting-edge piece of equipment that has reimagined the way sacks and bags are manufactured. With the ability to produce a wide range of bag types, sizes, and designs, this machine is setting new standards in the packaging sector.The Sack Bag Making Machine is renowned for its versatility and efficiency. Equipped with advanced automation and state-of-the-art technology, it can effortlessly handle large-scale production while maintaining precision and accuracy. This not only streamlines the manufacturing process but also significantly reduces production costs for businesses.One of the key features of the Sack Bag Making Machine is its ability to produce bags from a variety of materials. From basic polyethylene sacks to more complex multi-layered bags, this machine can accommodate different types of packaging requirements. This flexibility enables businesses to cater to diverse industries such as agriculture, food processing, chemical, and construction.The machine's user-friendly interface and intuitive controls make it easy for operators to set up and operate. In addition, its high-speed capabilities ensure maximum output without compromising on quality. This makes it an ideal choice for businesses looking to enhance their productivity and meet the growing demands of their customers.The Sack Bag Making Machine is designed with precision and durability in mind. Constructed from high-quality materials, it can withstand the rigors of continuous operation, ensuring a long service life. Its robust build and low maintenance requirements make it a cost-effective investment for businesses, delivering a high return on investment.Furthermore, this innovative machine incorporates various safety features to ensure the well-being of operators. From protective guards to emergency stop mechanisms, it prioritizes the safety of all those involved in its operation.One of the key advantages the Sack Bag Making Machine offers is its contribution to environmental sustainability. With an increasing emphasis on eco-friendly practices, this machine addresses the need for packaging solutions that minimize waste and environmental impact. By using materials that are recyclable and biodegradable, businesses can reduce their carbon footprint and contribute to a greener future.The Sack Bag Making Machine has already made waves in the packaging industry, garnering positive reviews from businesses worldwide. Its ability to provide customized packaging solutions, improve production efficiency, and minimize environmental impact has positioned it as a game-changer in the sector.As the global market continues to evolve, businesses must adapt to the changing dynamics and embrace technologies that streamline their operations. The Sack Bag Making Machine, with its advanced features and innovative design, offers a viable solution for businesses seeking to stay ahead in the competitive packaging industry.In conclusion, the Sack Bag Making Machine is revolutionizing the packaging industry with its versatility, efficiency, and commitment to sustainability. With this machine, businesses can meet the increasing demands of their customers while minimizing their environmental impact. As more businesses recognize the benefits of this groundbreaking technology, it is expected to become an integral part of the packaging process in various industries worldwide.

Efficient and High-Quality Cutting Solutions for Laminated Materials

Lamination Cutting Machine Offers Precise and Efficient Solutions for Various IndustriesIn today's rapidly evolving technological landscape, industries worldwide are constantly seeking innovative solutions to enhance their production processes. The lamination cutting machine, a cutting-edge tool designed for precision cutting in various industries, has emerged as a game-changer. Removing brand names, this versatile machine is helping companies streamline their operations, improve output quality, and minimize waste, giving them a competitive edge in the market.The lamination cutting machine revolutionizes the cutting process with its impressive capabilities. Built on cutting-edge technology, this machine's efficiency lies in its ability to seamlessly integrate with various production lines, adapting to the unique needs and requirements of different industries.Industries such as packaging, automotive, textile, and aerospace are benefiting tremendously from the lamination cutting machine's versatility. In the packaging industry, for example, where precision and speed are paramount, this machine ensures consistent cuts, regardless of the material being processed. From paper and cardboard to plastic and foil, the lamination cutting machine delivers high-quality results, reducing material waste and enhancing productivity.Moreover, in the automotive industry, where safety and reliability are of utmost importance, the lamination cutting machine plays a crucial role in ensuring high-quality components. It effortlessly cuts through various materials like rubber, foam, and gaskets, providing precise cuts that meet the industry's strict standards. This translates into enhanced performance and durability of automotive parts, ultimately ensuring customer satisfaction and brand loyalty.The textile industry is yet another sector where the lamination cutting machine shines. With its ability to handle a wide range of fabrics, including cotton, polyester, and nylon, this machine enables manufacturers to cut patterns accurately and efficiently. This translates into faster production cycles, reduced labor costs, and improved fabric utilization—an essential factor for companies in the fast-paced fashion industry.Furthermore, the aerospace industry leverages the lamination cutting machine's state-of-the-art technology to cut composite materials that are vital to building lightweight and durable aircraft components. These advanced materials, including carbon fiber and fiberglass, present challenges due to their unique properties. However, the lamination cutting machine seamlessly navigates these obstacles, ensuring precise cuts without compromising the integrity of the delicate materials.The lamination cutting machine also boasts a range of features that contribute to its popularity across industries. One of these features is its user-friendly interface, which enables operators to easily program cutting patterns, adjust parameters, and troubleshoot, minimizing human error and maximizing efficiency.Additionally, the machine's cutting accuracy is guaranteed by its advanced sensors and cutting mechanisms, ensuring that every cut is uniform and precise. Moreover, the lamination cutting machine boasts a high cutting speed, enabling it to handle large volumes of materials without compromising quality, making it a valuable asset for companies facing tight production deadlines.To further enhance its capabilities, the lamination cutting machine can be integrated with other manufacturing systems such as robotic arms and quality control devices. This integration enables seamless automation, reduces manual intervention, and eliminates potential bottlenecks in the production process. This results in increased output efficiency, reduced production costs, and improved overall product quality.In conclusion, the lamination cutting machine (removing brand names) has transformed the way industries approach cutting processes. Its versatility and adaptability make it a valuable asset in a wide range of industries, from packaging and automotive to textile and aerospace. By optimizing cutting precision, reducing material waste, and enhancing overall efficiency, this cutting-edge machine positions companies at the forefront of their respective markets. As technology continues to advance, it is clear that the lamination cutting machine will play an increasingly vital role in realizing efficient and sustainable production processes.

Revolutionary New Machine Increases Production Efficiency by 50%

[Company Name], a leading provider of advanced automation solutions, recently introduced its revolutionary PE Machine. Designed to enhance efficiency and productivity in the manufacturing industry, the PE Machine promises to revolutionize the way companies operate.With the advent of Industry 4.0, automation has become increasingly vital for manufacturers looking to gain a competitive edge. The PE Machine is at the forefront of this technological revolution, offering unparalleled capabilities in terms of speed, precision, and versatility.Equipped with state-of-the-art technology, the PE Machine is capable of performing a wide range of tasks with utmost precision. From product assembly to packaging, this innovative machine can handle it all. The machine's advanced sensors and intelligent algorithms ensure flawless operation, eliminating errors and minimizing downtime.One of the key features of the PE Machine is its flexibility. With its modular design, the machine can be easily reconfigured to accommodate different manufacturing processes and product specifications. This adaptability allows companies to optimize their production lines and respond quickly to changing market demands.The PE Machine's speed is another aspect that sets it apart from other automation solutions. With a high-speed processing unit, the machine can complete tasks in a fraction of the time it would take a human operator. This accelerated pace significantly boosts productivity and reduces production time, resulting in faster turnaround and increased output.Furthermore, the PE Machine's user-friendly interface makes it easy for operators to set up and monitor production processes. With intuitive controls and a digital display, users can quickly adjust settings and track performance in real-time. The machine also supports remote monitoring and control, enabling companies to oversee operations from anywhere at any time.In addition to its impressive features, the PE Machine is also highly energy-efficient. Equipped with energy management systems and advanced power-saving capabilities, the machine minimizes energy consumption without sacrificing performance. This eco-friendly approach not only reduces costs but also aligns with the sustainability goals of many companies.The introduction of the PE Machine comes at a time when manufacturers are striving to streamline their operations and remain competitive in a rapidly evolving market. By embracing automation and integrating innovative solutions like the PE Machine, companies can optimize efficiency, reduce costs, and meet the growing demands of their customers.[Company Name], known for its commitment to excellence and innovation, has a proven track record in delivering cutting-edge automation solutions to a wide range of industries. With the introduction of the PE Machine, the company reaffirms its dedication to transforming the manufacturing landscape and enabling companies to thrive in the age of automation.As the manufacturing industry continues to evolve, automation will undoubtedly play a crucial role in shaping its future. The PE Machine, with its advanced features and unmatched capabilities, paves the way for a new era of efficiency and productivity. With this groundbreaking solution, [Company Name] establishes its position as a leader in the automation industry, offering a glimpse into what the future holds for manufacturing.